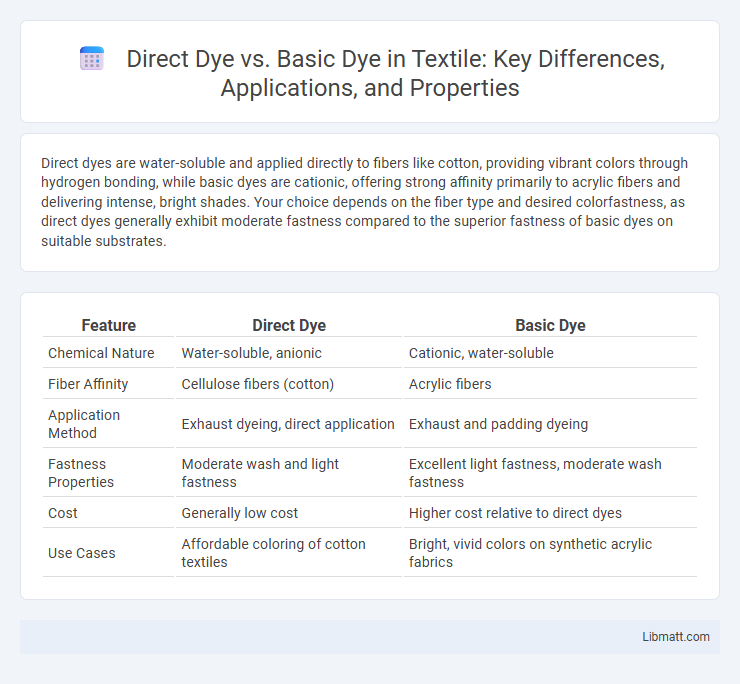

Direct dyes are water-soluble and applied directly to fibers like cotton, providing vibrant colors through hydrogen bonding, while basic dyes are cationic, offering strong affinity primarily to acrylic fibers and delivering intense, bright shades. Your choice depends on the fiber type and desired colorfastness, as direct dyes generally exhibit moderate fastness compared to the superior fastness of basic dyes on suitable substrates.

Table of Comparison

| Feature | Direct Dye | Basic Dye |

|---|---|---|

| Chemical Nature | Water-soluble, anionic | Cationic, water-soluble |

| Fiber Affinity | Cellulose fibers (cotton) | Acrylic fibers |

| Application Method | Exhaust dyeing, direct application | Exhaust and padding dyeing |

| Fastness Properties | Moderate wash and light fastness | Excellent light fastness, moderate wash fastness |

| Cost | Generally low cost | Higher cost relative to direct dyes |

| Use Cases | Affordable coloring of cotton textiles | Bright, vivid colors on synthetic acrylic fabrics |

Introduction to Direct and Basic Dyes

Direct dyes are water-soluble azo dyes primarily used for dyeing cellulose fibers such as cotton, providing vibrant colors through direct adsorption onto the fiber surface. Basic dyes, also known as cationic dyes, possess a positive charge and are mainly applied to acrylic fibers, ensuring bright, intense coloration with strong affinity via ionic bonding. Both dye types differ significantly in chemical structure, substantivity, and fiber compatibility, which influence their application and performance in textile dyeing processes.

Chemical Structure Differences

Direct dyes possess larger, planar molecules with sulfonic acid groups enhancing water solubility and fiber affinity, primarily used for cellulose fibers like cotton. Basic dyes contain smaller, cationic molecules with positively charged groups that bind strongly to negatively charged fibers such as acrylics and wool. Understanding these chemical structure differences enables you to select the appropriate dye type for optimal colorfastness and fabric compatibility.

Application Methods for Fabrics

Direct dyes are applied to fabrics primarily through immersion in a hot dye bath, allowing the dye molecules to penetrate cellulose fibers such as cotton via a simple dyeing process that requires minimal mordanting. Basic dyes use a different method, typically applied to acrylic fibers through a dye bath or printing, where their cationic nature enables strong affinity and vibrant coloration on synthetic fabrics. Your choice between direct and basic dyes depends on the fabric type and desired dyeing technique, optimizing color fastness and intensity.

Color Fastness Comparison

Direct dyes typically exhibit moderate color fastness to washing and light due to their substantive nature, making them suitable for cellulose fibers like cotton. Basic dyes, however, demonstrate superior color fastness to light and washing on synthetic fibers such as acrylic and polyester, owing to their cationic properties that enable strong fiber-dye interactions. Consequently, basic dyes are preferred for applications requiring vibrant hues with enhanced durability under frequent laundering and exposure.

Shade Range and Brightness

Direct dyes offer a broad shade range with rich, deep colors suitable for cotton and other cellulose fibers, although their brightness tends to be moderate due to lower affinity and dye uptake. Basic dyes provide exceptionally bright and vivid colors with high tinting strength, primarily used for acrylic fibers and paper, yet their shade range is narrower compared to direct dyes. Understanding these differences in shade range and brightness helps in selecting the appropriate dye type based on fabric compatibility and desired visual impact.

Key Uses in Textile Industry

Direct dyes are widely used for dyeing cotton, rayon, and other cellulosic fibers due to their excellent affinity and bright colors, making them ideal for printing and commercial fabric finishing. Basic dyes are primarily utilized for acrylic fibers and paper coloring, offering vibrant shades and strong brilliance but with limited wash fastness on natural fibers. Understanding your fabric type ensures optimal dye selection for durability and desired coloration in textile production.

Advantages of Direct Dyes

Direct dyes offer excellent ease of application with no need for mordants, making the dyeing process more environmentally friendly and cost-effective. They provide vibrant colors with good colorfastness on cellulose fibers such as cotton, enhancing durability in everyday use. Their ability to dye fibers at low temperatures reduces energy consumption, contributing to sustainable textile manufacturing.

Benefits of Basic Dyes

Basic dyes exhibit high affinity for negatively charged substrates such as acrylic fibers, providing vibrant and intense coloration with excellent brightness. Their strong cationic nature facilitates rapid dye uptake and superior wash fastness compared to direct dyes, making them ideal for textile applications requiring durable and vivid colors. Furthermore, basic dyes offer enhanced mordanting properties, resulting in improved color retention and resistance to fading under light exposure.

Environmental Impact and Safety

Direct dyes generally have a lower environmental impact compared to basic dyes because they are less toxic and more biodegradable, reducing water pollution risks during textile processing. Basic dyes often contain heavy metals and harmful chemicals that pose safety hazards to both workers and aquatic life due to their poor biodegradability and toxicity. Proper treatment of wastewater containing basic dyes is essential to minimize their long-term ecological damage and protect human health.

Choosing the Right Dye for Your Needs

Direct dyes are best suited for dyeing cellulose fibers such as cotton, offering easy application and good colorfastness without the need for mordants. Basic dyes, on the other hand, provide vibrant, intense colors primarily on acrylic and wool fibers but may require careful handling due to their affinity for cationic sites. Understanding the fiber type and desired color properties ensures you select the dye that maximizes performance and durability for your specific project.

Direct dye vs Basic dye Infographic

libmatt.com

libmatt.com