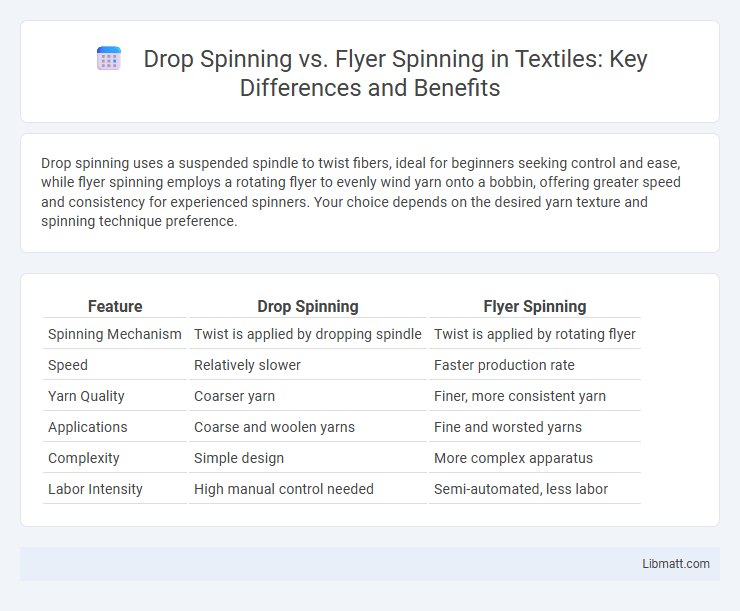

Drop spinning uses a suspended spindle to twist fibers, ideal for beginners seeking control and ease, while flyer spinning employs a rotating flyer to evenly wind yarn onto a bobbin, offering greater speed and consistency for experienced spinners. Your choice depends on the desired yarn texture and spinning technique preference.

Table of Comparison

| Feature | Drop Spinning | Flyer Spinning |

|---|---|---|

| Spinning Mechanism | Twist is applied by dropping spindle | Twist is applied by rotating flyer |

| Speed | Relatively slower | Faster production rate |

| Yarn Quality | Coarser yarn | Finer, more consistent yarn |

| Applications | Coarse and woolen yarns | Fine and worsted yarns |

| Complexity | Simple design | More complex apparatus |

| Labor Intensity | High manual control needed | Semi-automated, less labor |

Introduction to Drop Spinning and Flyer Spinning

Drop spinning and flyer spinning are traditional textile techniques used to twist fibers into yarn. Drop spinning involves a weighted spindle that twists the fiber by dropping and spinning simultaneously, producing fine and delicate yarns ideal for hand spinning. Flyer spinning uses a rotating flyer and bobbin system, allowing greater control over yarn tension and thickness, commonly utilized in mechanized spinning processes.

Historical Background of Spinning Techniques

Drop spinning dates back to ancient civilizations, with evidence of its use found in archeological sites from the Neolithic period, highlighting its role as one of the earliest spinning methods. Flyer spinning emerged later during the Industrial Revolution, revolutionizing textile production with its mechanized flyer arm designed to twist and wind fibers simultaneously, improving efficiency over the simpler drop spindle. Both techniques reflect significant advancements in textile technology, illustrating the evolution from manual craftsmanship to industrial manufacturing.

Key Equipment: Drop Spindle vs Spinning Wheel

Drop spinning utilizes a drop spindle, a simple handheld tool consisting of a weighted shaft that twists fibers into yarn through manual rotation. Flyer spinning employs a spinning wheel featuring a flyer mechanism that twists and winds yarn simultaneously, allowing for higher production speed and consistency. The drop spindle offers portability and ease of use for beginners, while the spinning wheel demands a stationary setup but provides greater efficiency for larger-scale yarn production.

Process and Technique Overview

Drop spinning involves twisting fibers by dropping a weighted spindle, allowing gravity to control the spin speed and tension, resulting in a more natural and consistent yarn. Flyer spinning uses a rotating flyer mechanism to twist and wind the fiber simultaneously, offering greater control over yarn thickness and tension. Your choice between these techniques depends on the desired yarn characteristics and personal mastery of spinning tools.

Material Compatibility and Yarn Types

Drop spinning excels in handling fine, delicate fibers such as silk and wool, producing lightweight, smooth yarns ideal for high-quality textiles. Flyer spinning accommodates a broader range of materials, including cotton, flax, and synthetic fibers, enabling the creation of both fine and coarse yarns with varied textures. Both methods influence yarn strength and uniformity, with flyer spinning offering greater versatility in producing diverse yarn types for different fabric applications.

Speed and Efficiency Comparison

Drop spinning generally offers slower production speeds but provides greater control over yarn tension, making it efficient for fine and delicate yarns. Flyer spinning achieves higher speed and volume output by simultaneously twisting and winding yarn, enhancing overall efficiency for large-scale manufacturing. Your choice between the two methods depends on whether speed or precision is the primary priority in your textile production process.

Portability and Space Requirements

Drop spinning offers superior portability due to its compact, lightweight design, making it ideal for spinners with limited space or those who travel frequently. Flyer spinning typically requires a larger, stationary wheel setup, demanding more dedicated space and less convenience in mobility. Choosing drop spinning can optimize your spinning experience when space constraints or portability are key considerations.

Learning Curve and Skill Development

Drop spinning offers a gentler learning curve, making it ideal for beginners seeking to develop foundational fiber control and drafting skills with less complexity. Flyer spinning demands more advanced hand coordination and tension management, accelerating your skill development in producing consistent yarn but requiring greater practice and precision. Mastering flyer spinning often leads to enhanced craftsmanship, while drop spinning provides a solid skill base for diverse spinning techniques.

Cost and Accessibility

Drop spinning requires minimal equipment, making it highly cost-effective and accessible for individual artisans and small-scale producers. Flyer spinning involves more complex machinery, resulting in higher initial investment and maintenance costs, which can limit accessibility to large-scale or industrial operations. The simplicity of drop spinning supports widespread use in regions with limited resources, while flyer spinning suits environments with greater capital and technical expertise.

Choosing the Right Method for Your Needs

Drop spinning offers greater simplicity and portability, making it ideal for small-scale or mobile fiber projects. Flyer spinning provides enhanced control over thread tension and thickness, suitable for more precise, high-volume yarn production. Selecting the right method depends on your fiber type, desired yarn consistency, and project scale.

Drop spinning vs Flyer spinning Infographic

libmatt.com

libmatt.com