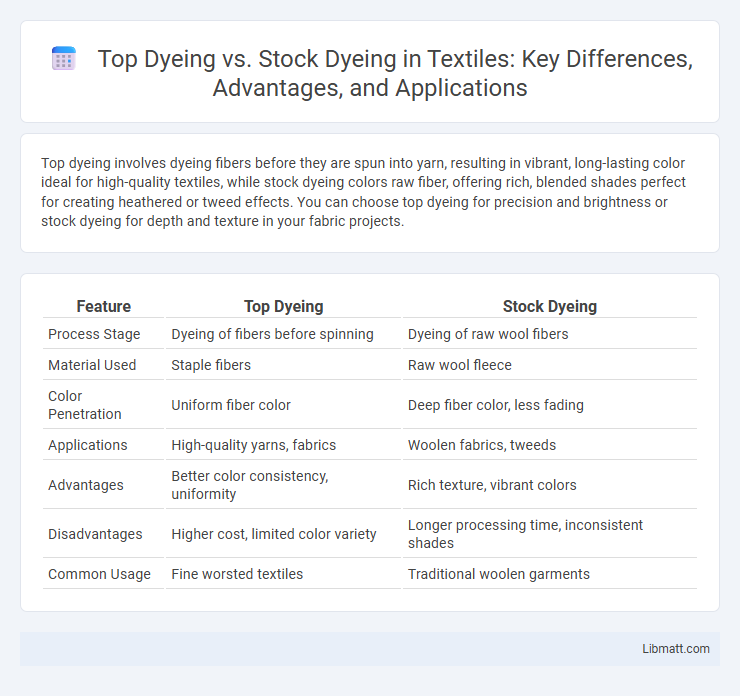

Top dyeing involves dyeing fibers before they are spun into yarn, resulting in vibrant, long-lasting color ideal for high-quality textiles, while stock dyeing colors raw fiber, offering rich, blended shades perfect for creating heathered or tweed effects. You can choose top dyeing for precision and brightness or stock dyeing for depth and texture in your fabric projects.

Table of Comparison

| Feature | Top Dyeing | Stock Dyeing |

|---|---|---|

| Process Stage | Dyeing of fibers before spinning | Dyeing of raw wool fibers |

| Material Used | Staple fibers | Raw wool fleece |

| Color Penetration | Uniform fiber color | Deep fiber color, less fading |

| Applications | High-quality yarns, fabrics | Woolen fabrics, tweeds |

| Advantages | Better color consistency, uniformity | Rich texture, vibrant colors |

| Disadvantages | Higher cost, limited color variety | Longer processing time, inconsistent shades |

| Common Usage | Fine worsted textiles | Traditional woolen garments |

Introduction to Top Dyeing and Stock Dyeing

Top dyeing involves coloring fibers before they are spun into yarn, ensuring uniform and vibrant hues ideal for high-quality textiles. Stock dyeing refers to the process of dyeing raw fibers in loose, unspun form, allowing for excellent color penetration and blending potential in wool and other natural fibers. Both methods are integral to textile manufacturing, influencing fabric appearance, texture, and dye-fastness.

What is Top Dyeing?

Top dyeing refers to the process of dyeing fibers after they have been carded and aligned into a sliver but before spinning them into yarn. This technique ensures more uniform color distribution and vibrant shades throughout the fiber, resulting in high-quality, consistent yarn. You can achieve precise color control with top dyeing, making it ideal for premium textile production.

What is Stock Dyeing?

Stock dyeing is a textile dyeing process where raw fibers or yarns are dyed before they are spun into fabric, enabling deep color penetration and excellent color fastness. This method offers greater control over the intensity and uniformity of shades, making it ideal for producing vibrant and long-lasting colors in wool and other staple fibers. You benefit from enhanced durability and consistency in the final fabric, especially for high-quality garments and upholstery.

Key Differences Between Top Dyeing and Stock Dyeing

Top dyeing involves applying color to the finished fabric, allowing for precise color control and vibrant patterns, while stock dyeing colors the fibers before spinning, resulting in better colorfastness and uniformity. You benefit from top dyeing when detailed designs are required, whereas stock dyeing excels in producing consistent shades for bulk textile production. Understanding these key differences helps determine the most suitable dyeing process for your textile needs.

Advantages of Top Dyeing

Top dyeing offers superior color uniformity and penetration compared to stock dyeing, ensuring consistent and vibrant fabric appearance. It allows for better control over specific sections of the fiber, leading to enhanced design precision and reduced color wastage. This method also improves fabric softness and tensile strength, making it a preferred choice for high-quality textile production.

Advantages of Stock Dyeing

Stock dyeing offers superior color consistency and long-term colorfastness, making it ideal for fabrics requiring uniformity throughout production. This method allows for greater flexibility in inventory management, as undyed fibers can be stored and dyed on demand to match specific color requirements. Your manufacturing process benefits from reduced waste and enhanced dye penetration, resulting in higher-quality textiles.

Disadvantages of Top Dyeing

Top dyeing often results in inconsistent color penetration, leading to uneven shades and potential color fading after washing. The process can also weaken fabric fibers due to repeated exposure to dye chemicals, reducing garment durability. Higher production costs and longer turnaround times make top dyeing less efficient compared to stock dyeing.

Disadvantages of Stock Dyeing

Stock dyeing often results in higher production costs due to the dyeing of large fabric quantities before garment manufacturing. There is limited flexibility in color customization as the entire fabric batch is dyed uniformly, increasing the risk of excess inventory if demand shifts. Color matching issues may arise when mixing dyed stock with other materials, causing inconsistencies in final garment hues.

Applications and End-Uses

Top dyeing offers precise color control and vibrant hues ideal for high-end fashion, upholstery, and premium home textiles, where fabric quality and color fastness are critical. Stock dyeing, also known as fiber dyeing, excels in producing heathered and melange effects for yarns used in casual wear, sports apparel, and artisanal knits, providing better depth and color blending before fabric formation. Applications involving complex color patterns and consistency often favor top dyeing, while stock dyeing suits mass production of varied textures and tonal ranges.

Choosing the Right Dyeing Method

Choosing the right dyeing method depends on fabric type, production volume, and desired colorfastness. Top dyeing is ideal for natural, durable fibers offering deep color penetration, while stock dyeing provides vibrant hues for synthetic and blended fabrics with superior color uniformity. Your decision should balance cost efficiency and fabric performance to ensure optimal results.

Top dyeing vs Stock dyeing Infographic

libmatt.com

libmatt.com