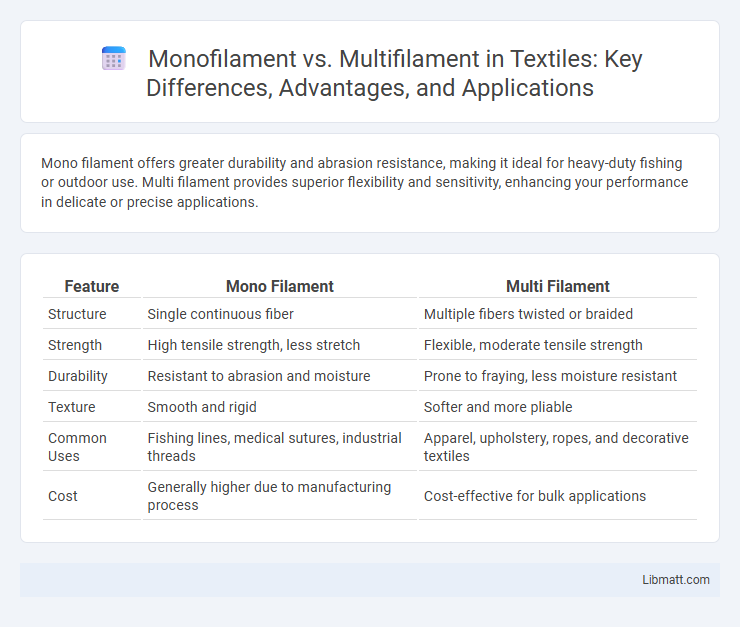

Mono filament offers greater durability and abrasion resistance, making it ideal for heavy-duty fishing or outdoor use. Multi filament provides superior flexibility and sensitivity, enhancing your performance in delicate or precise applications.

Table of Comparison

| Feature | Mono Filament | Multi Filament |

|---|---|---|

| Structure | Single continuous fiber | Multiple fibers twisted or braided |

| Strength | High tensile strength, less stretch | Flexible, moderate tensile strength |

| Durability | Resistant to abrasion and moisture | Prone to fraying, less moisture resistant |

| Texture | Smooth and rigid | Softer and more pliable |

| Common Uses | Fishing lines, medical sutures, industrial threads | Apparel, upholstery, ropes, and decorative textiles |

| Cost | Generally higher due to manufacturing process | Cost-effective for bulk applications |

Introduction to Monofilament and Multifilament

Monofilament fishing lines consist of a single, continuous strand of nylon, providing high abrasion resistance and stretch, making them ideal for beginners and versatile fishing conditions. Multifilament lines, made from multiple braided fibers, offer superior sensitivity, strength, and less stretch, improving hook-setting power and performance in clear water. Your choice between monofilament and multifilament will depend on your fishing style, target species, and specific environmental factors.

Defining Monofilament: Features and Structure

Monofilament fishing line consists of a single, continuous strand of nylon or similar synthetic material, providing uniform strength and durability. Its smooth surface reduces water resistance and enhances casting distance, while the elasticity offers shock absorption to prevent line breakage during sudden tension. The simple structure results in less stretch compared to multifilament lines, making it ideal for detecting subtle bites and improving control.

Understanding Multifilament: Composition and Characteristics

Multifilament fishing lines consist of multiple fine fibers braided or twisted together, creating a strong, flexible, and sensitive line with excellent knot strength and abrasion resistance. These lines are typically made from materials such as braided polyethylene or nylon, offering enhanced smoothness and reduced stretch compared to monofilament lines. The complex fiber structure of multifilament lines provides superior casting performance and increased sensitivity, making them ideal for various fishing techniques requiring precision and durability.

Key Differences Between Monofilament and Multifilament

Monofilament fishing lines consist of a single strand of material, offering higher abrasion resistance and greater durability, making them ideal for rough conditions. Multifilament lines, made from multiple braided fibers, provide superior sensitivity, flexibility, and knot strength, enhancing your ability to detect bites and improve casting performance. The choice between monofilament and multifilament depends on your specific fishing environment and technique preferences.

Performance Comparison: Strength, Flexibility, and Durability

Monofilament fishing lines offer superior strength and durability due to their single, solid strand construction, making them ideal for heavy-duty fishing and resisting abrasion. Multifilament lines, composed of multiple intertwined fibers, provide enhanced flexibility and sensitivity, allowing you to detect subtle bites more effectively. Choosing between monofilament and multifilament depends on your specific fishing needs, where durability and strength contrast with the need for flexibility and precision.

Applications of Monofilament in Various Industries

Monofilament fibers are widely used in industries such as fishing, textile manufacturing, and medical sutures due to their strength, durability, and resistance to abrasion. You'll find monofilament in applications requiring precision and longevity, including fishing lines, surgical threads, and industrial filters. Their single-strand construction offers superior tensile strength and minimal stretch, making them ideal for products demanding consistent performance under stress.

Uses of Multifilament Across Different Sectors

Multifilament fibers are widely used in various sectors due to their flexibility, strength, and softness, making them ideal for textile manufacturing, including sportswear, lingerie, and upholstery fabrics. In the medical industry, multifilament sutures provide enhanced knot security and pliability, improving wound healing outcomes. The fishing industry relies on multifilament lines for their high tensile strength and abrasion resistance, ensuring durability and performance in diverse aquatic environments.

Pros and Cons: Monofilament vs Multifilament

Monofilament fishing lines offer high durability, excellent abrasion resistance, and low stretch, providing strong hook-setting power but can be less sensitive and prone to memory issues. Multifilament lines boast superior sensitivity, lower diameter for the same strength, and greater flexibility, yet they tend to absorb water, reducing strength over time and are more susceptible to abrasion. Your choice depends on whether you prioritize strength and durability with monofilament or sensitivity and finesse with multifilament.

Choosing the Right Filament for Your Needs

Choosing the right filament depends on the specific application: monofilament offers higher abrasion resistance and durability, making it ideal for fishing lines and outdoor gear exposed to rough conditions. Multifilament features superior flexibility and softness, preferred for activities requiring sensitive touch, such as fly fishing or sewing delicate fabrics. Understanding the performance characteristics of each filament type ensures optimal strength, comfort, and overall effectiveness tailored to your project requirements.

Future Trends in Filament Technology

Future trends in filament technology emphasize the development of hybrid filaments combining the strength of monofilament with the flexibility of multifilament for enhanced performance in diverse applications. Advances in nanomaterials and bio-based polymers aim to create filaments with superior durability, environmental sustainability, and improved mechanical properties. Innovations such as smart filaments with embedded sensors and self-healing capabilities are poised to transform industries like textiles, medical devices, and automotive manufacturing.

Mono filament vs Multi filament Infographic

libmatt.com

libmatt.com