Rope dyeing offers deeper color penetration and better yarn-to-yarn dye consistency compared to slasher dyeing, making it ideal for high-quality denim production. Your choice depends on fabric type and desired finish, with slasher dyeing providing a faster, more economical process suitable for lighter weight fabrics.

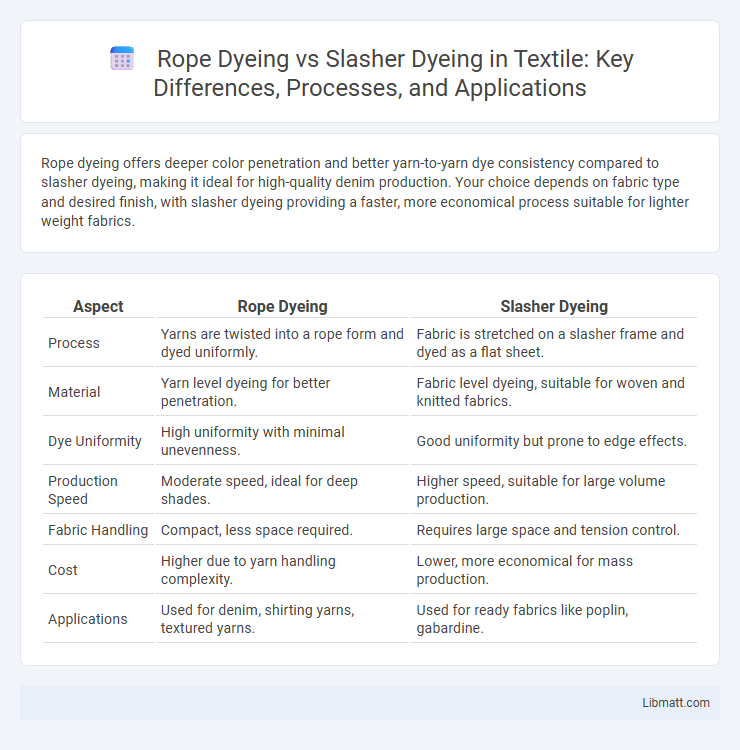

Table of Comparison

| Aspect | Rope Dyeing | Slasher Dyeing |

|---|---|---|

| Process | Yarns are twisted into a rope form and dyed uniformly. | Fabric is stretched on a slasher frame and dyed as a flat sheet. |

| Material | Yarn level dyeing for better penetration. | Fabric level dyeing, suitable for woven and knitted fabrics. |

| Dye Uniformity | High uniformity with minimal unevenness. | Good uniformity but prone to edge effects. |

| Production Speed | Moderate speed, ideal for deep shades. | Higher speed, suitable for large volume production. |

| Fabric Handling | Compact, less space required. | Requires large space and tension control. |

| Cost | Higher due to yarn handling complexity. | Lower, more economical for mass production. |

| Applications | Used for denim, shirting yarns, textured yarns. | Used for ready fabrics like poplin, gabardine. |

Introduction to Denim Dyeing Methods

Rope dyeing involves twisting yarns into a rope form before dyeing, allowing deep indigo penetration for durable, authentic denim with highly sought-after fading properties. Slasher dyeing, also known as sheet dyeing, passes yarns in flat sheets through dye baths, offering higher production speed and cost efficiency but less intense color depth. Both methods play crucial roles in denim manufacturing, balancing dye uniformity, fabric aesthetics, and production scalability.

What is Rope Dyeing?

Rope dyeing is a fabric dyeing method where yarns are tightly twisted into a rope form before being immersed in dye baths, ensuring uniform color penetration and minimal tension on fibers. This process is widely used for denim production due to its ability to produce deep indigo shades with excellent colorfastness and fabric softness. Compared to slasher dyeing, rope dyeing allows precise control over dye absorption, resulting in higher-quality finished textiles.

What is Slasher Dyeing?

Slasher dyeing is a continuous fabric dyeing process where woven fabric is passed through dye baths in a rope form and then spread out to dry, offering efficient color absorption and uniformity. Compared to rope dyeing, which involves dyeing yarns before weaving, slasher dyeing works directly on the fabric, reducing production time and costs. Your choice between these methods depends on fabric type and desired color fastness, with slasher dyeing favored for high-volume, consistent fabric dyeing.

Comparison of Dyeing Processes

Rope dyeing involves twisting fabric into a rope form before dyeing, ensuring even color penetration and superior colorfastness, especially for denim. Slasher dyeing passes the fabric in open width under dye baths, offering higher production speed but sometimes less uniform dyeing quality. The choice between rope and slasher dyeing depends on fabric type, desired color consistency, and production efficiency requirements.

Color Consistency and Dye Penetration

Rope dyeing offers superior color consistency due to the fabric being tightly twisted into a rope, allowing even exposure to dyes and reducing uneven patches. Dye penetration in rope dyeing is deep and thorough, ensuring vibrant and long-lasting color absorption throughout the fabric fibers. In contrast, slasher dyeing provides quicker processing but often results in less uniform color consistency and shallower dye penetration, which can affect the overall durability and vibrancy of the fabric's color.

Production Efficiency: Rope vs Slasher

Rope dyeing offers higher production efficiency due to continuous processing of fabric in rope form, enabling deeper color penetration and reduced water usage. Slasher dyeing, while suitable for high-volume runs, involves fabric running flat and requires more water and energy, resulting in slower throughput. Your choice between rope and slasher dyeing impacts overall productivity and sustainability depending on fabric type and batch size.

Impact on Fabric Quality

Rope dyeing enhances fabric quality by allowing thorough dye penetration and producing uniform color fastness, making it ideal for high-quality denim and woven fabrics. Slasher dyeing, while faster and more economical, may result in less consistent dye absorption and surface color variations due to its continuous processing method. Your choice between these methods will directly affect the fabric's durability, texture, and overall aesthetic.

Environmental Considerations

Rope dyeing generally consumes less water and energy compared to slasher dyeing, making it a more environmentally friendly option for fabric processing. The continuous processing in rope dyeing reduces chemical waste and lowers the overall effluent load released into the environment. Slasher dyeing, involving flat fabric handling, often results in higher water usage and more chemical discharge, increasing the environmental impact.

Cost Implications of Each Method

Rope dyeing typically incurs higher initial costs due to the complex machinery and longer processing time required, but it offers superior dye penetration and uniformity, which can reduce waste and reprocessing expenses in high-quality fabric production. Slasher dyeing is generally more cost-effective for large-scale production with faster throughput and lower energy consumption, making it suitable for basic fabric dyeing where color precision and depth are less critical. Evaluating the total cost impact involves balancing dye quality requirements against production volume and energy usage for each method.

Choosing the Right Dyeing Technique

Selecting the appropriate dyeing technique depends on fabric type, production volume, and desired colorfastness; rope dyeing excels with lightweight or delicate yarns, ensuring uniform color penetration and minimal tension, while slasher dyeing is ideal for flat fabrics requiring rapid processing and cost efficiency. Rope dyeing offers superior dye uptake and fabric hand, making it preferable for high-quality textiles demanding vibrant, long-lasting colors. Slasher dyeing supports continuous processing, reducing dye liquor usage and enabling faster turnaround for large-scale manufacturing.

Rope dyeing vs Slasher dyeing Infographic

libmatt.com

libmatt.com