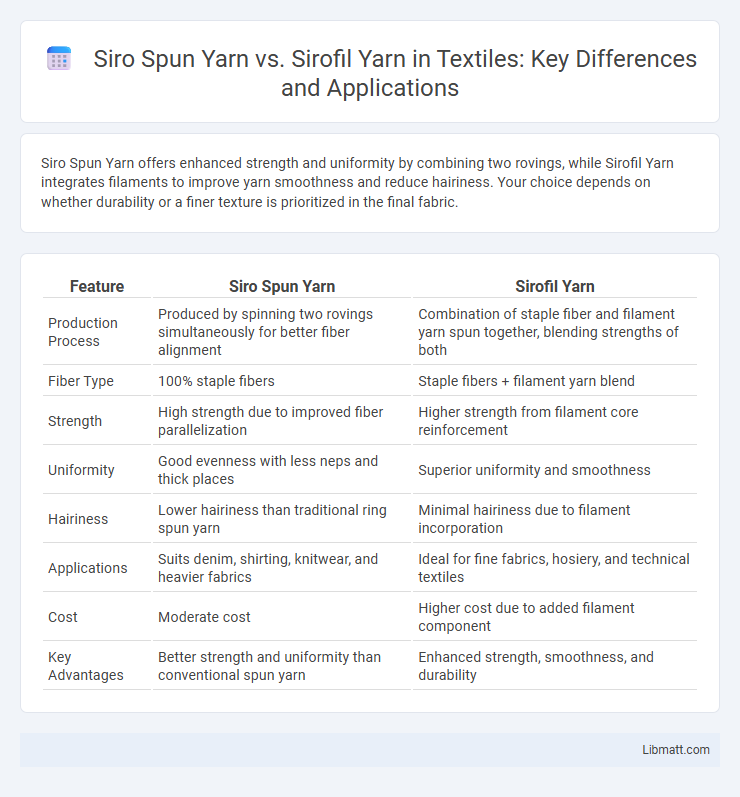

Siro Spun Yarn offers enhanced strength and uniformity by combining two rovings, while Sirofil Yarn integrates filaments to improve yarn smoothness and reduce hairiness. Your choice depends on whether durability or a finer texture is prioritized in the final fabric.

Table of Comparison

| Feature | Siro Spun Yarn | Sirofil Yarn |

|---|---|---|

| Production Process | Produced by spinning two rovings simultaneously for better fiber alignment | Combination of staple fiber and filament yarn spun together, blending strengths of both |

| Fiber Type | 100% staple fibers | Staple fibers + filament yarn blend |

| Strength | High strength due to improved fiber parallelization | Higher strength from filament core reinforcement |

| Uniformity | Good evenness with less neps and thick places | Superior uniformity and smoothness |

| Hairiness | Lower hairiness than traditional ring spun yarn | Minimal hairiness due to filament incorporation |

| Applications | Suits denim, shirting, knitwear, and heavier fabrics | Ideal for fine fabrics, hosiery, and technical textiles |

| Cost | Moderate cost | Higher cost due to added filament component |

| Key Advantages | Better strength and uniformity than conventional spun yarn | Enhanced strength, smoothness, and durability |

Introduction to Siro Spun Yarn and Sirofil Yarn

Siro Spun Yarn is a two-end yarn produced by simultaneously spinning two rovings, enhancing strength and uniformity, commonly used in textiles requiring durability and smooth texture. Sirofil Yarn, on the other hand, integrates filament fibers with staple fibers in a single spinning process, combining the strength of filaments with the softness of cotton or wool. Both yarn types improve fabric performance and feel, with Siro Spun ideal for woven and knitted fabrics and Sirofil suited for applications demanding higher tensile strength and sheen.

What is Siro Spun Yarn?

Siro Spun Yarn is a unique type of yarn created by spinning two strands of fiber simultaneously, resulting in a stronger and finer yarn compared to traditional ring-spun yarn. This innovative spinning process enhances fiber alignment and reduces pilling, making it popular in premium textile applications where durability and smoothness are essential. Your choice of Siro Spun Yarn offers improved fabric strength and a softer hand feel, ideal for high-quality garments.

What is Sirofil Yarn?

Sirofil yarn is a hybrid yarn made by combining staple fibers with filament fibers through the siro spinning process, resulting in enhanced strength, uniformity, and smoothness compared to traditional spun yarns. This yarn offers lower hairiness and higher tensile strength, making it ideal for high-performance textiles and applications requiring durability and softness. Unlike siro spun yarn, which uses only staple fibers, sirofil yarn integrates continuous filaments to improve fabric quality and appearance.

Key Differences Between Siro Spun and Sirofil Yarn

Siro Spun Yarn is made by twisting two parallel slivers simultaneously, resulting in a soft yet strong yarn ideal for fine textiles, while Sirofil Yarn combines filaments with staple fibers, offering enhanced strength and uniformity suitable for durable fabrics. The key differences lie in their production processes and fiber compositions, where Siro Spun emphasizes natural fiber cohesion and Sirofil integrates filament fibers for higher performance. Your choice between these yarns depends on the fabric's desired texture, strength, and application requirements.

Yarn Manufacturing Processes: Siro Spun vs Sirofil

Siro Spun yarn is produced using a modified ring spinning process where two rovings are fed simultaneously into the drafting system, creating a softer, stronger yarn with reduced hairiness. Sirofil yarn manufacturing integrates an air-jet technique that combines staple fibers with continuous filaments, enhancing yarn uniformity and tensile strength. These distinct processes affect the yarn's texture, durability, and application suitability in textile production.

Comparative Yarn Properties and Characteristics

Siro Spun Yarn offers a unique blend of strength and softness due to its dual air-jet spinning process, producing a compact and uniform yarn ideal for durable fabrics. Sirofil Yarn, combining filament and staple fibers, provides enhanced smoothness and reduced hairiness, which improves fabric sheen and reduces pilling. Understanding these comparative yarn properties helps you choose the right yarn for your textile applications, balancing durability, texture, and aesthetic qualities.

Applications and Uses in the Textile Industry

Siro Spun Yarn is widely used in apparel and home textiles due to its strength and smooth texture, making it ideal for woven and knitted fabrics. Sirofil Yarn combines filament and spun yarn properties, offering durability and a lustrous finish, commonly applied in high-performance garments and upholstery. Your choice between these yarns depends on the desired fabric characteristics, such as softness, durability, and appearance, tailored to specific textile industry applications.

Advantages and Disadvantages of Siro Spun Yarn

Siro Spun Yarn offers enhanced strength and uniformity due to its two parallel rovings twisted together, resulting in reduced hairiness and improved fabric appearance compared to conventional yarns. Its disadvantages include higher production costs and slightly lower softness compared to Sirofil yarn, which combines Siro spinning with filament fiber for extra smoothness and sheen. Understanding these trade-offs helps you choose the right yarn based on your fabric durability and texture requirements.

Pros and Cons of Sirofil Yarn

Sirofil yarn combines the benefits of spun yarn and filament yarn, offering high strength, smooth texture, and enhanced durability, making it ideal for both apparel and industrial uses. Its consistent quality reduces pilling and increases fabric longevity, but it may come at a higher cost compared to traditional Siro spun yarn. You can achieve superior fabric performance with Sirofil yarn, though the initial investment might be a consideration for budget-sensitive projects.

Choosing the Right Yarn: Siro Spun or Sirofil?

Choosing between Siro Spun yarn and Sirofil yarn depends on your desired fabric qualities and end-use. Siro Spun yarn offers enhanced strength and uniformity through its twin-filament spinning process, making it ideal for durable textiles and high-performance garments. Sirofil yarn combines the softness of staple fibers with the strength of filament fibers, providing a balanced texture perfect for comfortable yet resilient fabrics suited to your specific project needs.

Siro Spun Yarn vs Sirofil Yarn Infographic

libmatt.com

libmatt.com