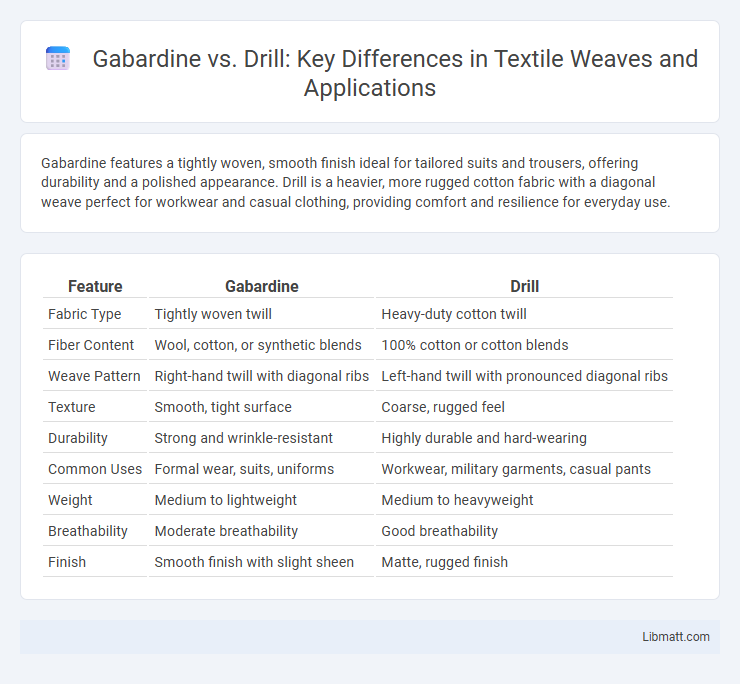

Gabardine features a tightly woven, smooth finish ideal for tailored suits and trousers, offering durability and a polished appearance. Drill is a heavier, more rugged cotton fabric with a diagonal weave perfect for workwear and casual clothing, providing comfort and resilience for everyday use.

Table of Comparison

| Feature | Gabardine | Drill |

|---|---|---|

| Fabric Type | Tightly woven twill | Heavy-duty cotton twill |

| Fiber Content | Wool, cotton, or synthetic blends | 100% cotton or cotton blends |

| Weave Pattern | Right-hand twill with diagonal ribs | Left-hand twill with pronounced diagonal ribs |

| Texture | Smooth, tight surface | Coarse, rugged feel |

| Durability | Strong and wrinkle-resistant | Highly durable and hard-wearing |

| Common Uses | Formal wear, suits, uniforms | Workwear, military garments, casual pants |

| Weight | Medium to lightweight | Medium to heavyweight |

| Breathability | Moderate breathability | Good breathability |

| Finish | Smooth finish with slight sheen | Matte, rugged finish |

Introduction to Gabardine and Drill

Gabardine is a tightly woven fabric known for its smooth finish and durability, primarily made from wool, cotton, or blends, often used in suiting and outerwear. Drill fabric features a strong, heavy-duty cotton weave with a distinct diagonal pattern, favored for workwear and military uniforms due to its ruggedness. Understanding the differences in texture, weight, and typical applications between gabardine and drill helps you select the best fabric for your garment or project needs.

Historical Origins of Gabardine and Drill

Gabardine, invented by Thomas Burberry in 1879, was designed as a durable, tightly woven fabric used initially for outdoor and military clothing, renowned for its waterproof qualities due to its twill weave. Drill fabric originated in the United States during the early 20th century as a heavy-duty cotton cloth used for workwear and military uniforms, prized for its strength and durability. Understanding the historical origins of gabardine and drill highlights their evolution into versatile fabrics ideal for your tailored garments and rugged apparel.

Fabric Composition and Weave Structure

Gabardine is typically composed of tightly woven worsted wool or cotton, featuring a distinctive twill weave with diagonal ribs that create a smooth, durable surface. Drill fabric, often made from cotton or cotton blends, uses a heavier, more pronounced twill weave with a stronger diagonal grain, resulting in a sturdier and more rigid texture. The differences in fiber content and twill tightness influence gabardine's sleek appearance versus drill's rugged durability.

Key Differences in Texture and Weight

Gabardine features a tightly woven, smooth texture with a twill weave, resulting in a firm yet flexible fabric often used in suiting and outerwear. Drill has a coarser, heavier texture with a more open twill weave, known for its durability and use in workwear and military uniforms. The weight of gabardine is typically lighter compared to the denser, heavier drill fabric, making gabardine more suitable for tailored garments.

Durability and Wear Resistance Comparison

Gabardine features a tightly woven twill weave made from worsted wool or cotton, providing exceptional durability and smooth surface wear resistance ideal for formal garments. Drill fabric, characterized by its strong cotton twill weave, offers high abrasion resistance and robustness, making it suitable for workwear and uniforms that endure heavy use. While both fabrics are durable, gabardine excels in wrinkle resistance and smooth texture, whereas drill stands out for its toughness and ability to withstand rough conditions.

Common Applications in Fashion and Industry

Gabardine is widely used in fashion for tailored suits, trench coats, and uniforms due to its smooth texture and durability, providing a polished and professional appearance. Drill fabric, characterized by its heavy-duty twill weave, is favored in industrial and workwear applications such as overalls, utility jackets, and military gear for its robustness and resistance to abrasion. Both fabrics excel in creating functional yet stylish apparel, with gabardine focusing more on formal wear and drill serving heavy-duty, practical needs.

Comfort and Breathability Factors

Gabardine features a tight weave with a smooth finish, providing moderate breathability while maintaining durability, making it comfortable for both casual and formal wear. Drill fabric, characterized by a sturdy twill weave, offers enhanced breathability and softness, ideal for active use and warmer climates. Choosing between gabardine and drill depends on your preference for a balance between comfort, breathability, and the intended garment's purpose.

Care, Maintenance, and Longevity

Gabardine fabric requires gentle care, ideally dry cleaning or hand washing in cold water to maintain its tight weave and smooth finish, which preserves its durability and wrinkle resistance over time. Drill fabric, made from heavier cotton twill, can withstand machine washing and regular use, offering excellent longevity with minimal maintenance, thanks to its rugged construction. Proper storage away from direct sunlight and prompt stain treatment extend the lifespan of both gabardine and drill textiles, ensuring long-lasting performance.

Environmental Impact and Sustainability

Gabardine, woven from tightly spun wool or polyester, often requires intensive processing that can contribute to water pollution and increased carbon emissions, while drill fabric, typically made from cotton, involves high water usage and pesticide application during cultivation. Sustainable options within both fabrics include organic cotton drill and recycled polyester gabardine, which reduce environmental impact by conserving resources and minimizing chemical use. Your choice between gabardine and drill can support eco-friendly fashion when prioritizing sustainably sourced and certified textile materials.

Choosing Between Gabardine and Drill: Which Is Better?

Gabardine offers a smooth, tightly woven fabric ideal for formal garments, providing durability and a refined appearance, while drill features a heavier, coarser weave suited for workwear and casual use due to its rugged strength. Selecting between gabardine and drill depends on the garment's intended purpose: gabardine excels in tailored suits and uniforms requiring a polished finish, whereas drill is better for heavy-duty items like utility trousers and jackets. Consider fabric weight, weave, and end-use requirements to determine if gabardine's sleek finish or drill's robust texture best meets your project needs.

Gabardine vs Drill Infographic

libmatt.com

libmatt.com