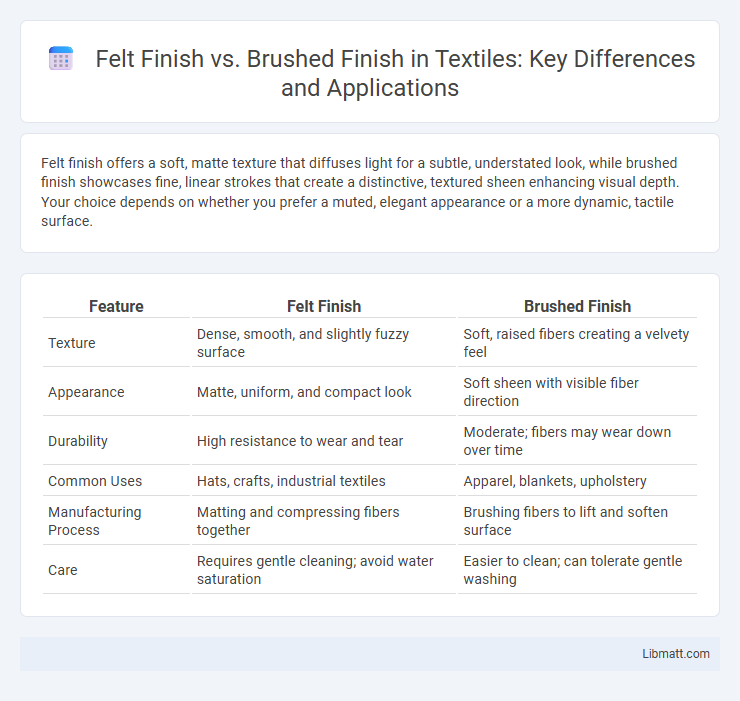

Felt finish offers a soft, matte texture that diffuses light for a subtle, understated look, while brushed finish showcases fine, linear strokes that create a distinctive, textured sheen enhancing visual depth. Your choice depends on whether you prefer a muted, elegant appearance or a more dynamic, tactile surface.

Table of Comparison

| Feature | Felt Finish | Brushed Finish |

|---|---|---|

| Texture | Dense, smooth, and slightly fuzzy surface | Soft, raised fibers creating a velvety feel |

| Appearance | Matte, uniform, and compact look | Soft sheen with visible fiber direction |

| Durability | High resistance to wear and tear | Moderate; fibers may wear down over time |

| Common Uses | Hats, crafts, industrial textiles | Apparel, blankets, upholstery |

| Manufacturing Process | Matting and compressing fibers together | Brushing fibers to lift and soften surface |

| Care | Requires gentle cleaning; avoid water saturation | Easier to clean; can tolerate gentle washing |

Introduction to Metal Finishes

Metal finishes such as felt and brushed finishes play a crucial role in determining the texture, appearance, and functionality of metal surfaces in various applications. Felt finishes provide a soft, matte look with a slightly textured surface, ideal for reducing glare and enhancing tactile appeal. Brushed finishes, characterized by fine parallel lines created through abrasive brushing, offer a modern, sleek aesthetic that improves resistance to scratches and fingerprints.

What is Felt Finish?

Felt finish is a unique surface texture created by subjecting metal, wood, or other materials to a controlled abrasive process that produces a soft, matte-like appearance with tiny, closely spaced indentations. This finish enhances tactile sensation and reduces surface glare, making it ideal for decorative applications and functional components where grip or subtle aesthetics are important. Felt finish also improves scratch resistance and hides fingerprints, distinguishing it from the more reflective and linear pattern of a brushed finish.

What is Brushed Finish?

Brushed finish is a surface treatment that creates a distinctive texture by using an abrasive belt or wire brush to produce fine, uniform scratches on metal or wood surfaces. This technique enhances the material's aesthetic appeal while also reducing glare and hiding minor imperfections. Commonly applied in stainless steel appliances, automotive parts, and furniture, brushed finishes offer a modern, matte look with increased durability.

Key Differences Between Felt and Brushed Finishes

Felt finish offers a smooth, matte surface achieved by pressing fabric against the material, creating a soft texture and reducing glare, while brushed finish involves mechanically abrading the surface with wire brushes, resulting in a textured, directional grain that enhances durability and hides scratches. The felt finish is ideal for applications requiring a low-reflective, gentle feel, whereas brushed finishes are preferred for industrial and aesthetic uses needing enhanced grip and resilience. Your choice depends on whether you prioritize tactile softness or textured robustness in the final product.

Visual Appearance Comparison

Felt finish offers a smooth, matte surface with a soft, muted texture that minimizes reflections, creating a subtle and elegant visual appeal. Brushed finish features fine, linear grooves resulting from abrasive brushing, producing a satin-like metallic sheen with visible texture and directional grain that enhances depth and character. Your choice between felt and brushed finishes will impact the overall look, with felt providing a more understated and uniform appearance, while brushed adds dynamic texture and light play.

Durability and Maintenance

Felt finishes offer moderate durability but tend to show wear and stains more easily, requiring gentle cleaning methods to maintain their texture. Brushed finishes provide superior durability due to their textured surface, which effectively hides scratches and fingerprints while necessitating only routine cleaning for upkeep. Your choice between felt and brushed finishes should consider the balance between desired aesthetic and long-term maintenance efforts.

Applications and Ideal Uses

Felt finish is ideal for applications requiring a matte, smooth surface that minimizes light reflection, commonly used in luxury automotive interiors and high-end furniture to enhance tactile comfort and aesthetic appeal. Brushed finish, characterized by its linear texture and subtle sheen, is perfect for metal surfaces in kitchen appliances, architectural panels, and electronic devices, offering increased durability and a modern look while hiding fingerprints and scratches. You can select felt finish for soft, understated elegance, whereas brushed finish suits environments demanding both functionality and contemporary style.

Cost Considerations

Felt finish typically incurs a higher cost due to the specialized materials and labor-intensive process required to achieve its soft, textured surface. Brushed finish is generally more cost-effective, benefiting from a quicker manufacturing process and less expensive tooling. These cost differences influence project budgets, with felt finishes often reserved for premium applications and brushed finishes favored for their affordability and durability.

Pros and Cons of Each Finish

Felt finish offers a smooth, velvety texture that resists fingerprints and minor scratches, making it ideal for surfaces needing a refined appearance, but it can be harder to clean if dirt embeds in the texture. Brushed finish provides a sleek, linear grain that hides scratches and wear over time, enhancing durability but may attract more visible smudges and require regular maintenance to keep its luster. Your choice depends on balancing aesthetics with practical wear resistance and ease of cleaning for the intended application.

Choosing the Right Finish for Your Project

Choosing the right finish for your project depends on the desired texture and durability. Felt finish offers a soft, matte surface ideal for diffusing light and reducing glare, making it perfect for delicate art or crafts. Brushed finish provides a sleek, directional texture with enhanced scratch resistance, suitable for metal surfaces and industrial design applications where robustness is key.

Felt finish vs Brushed finish Infographic

libmatt.com

libmatt.com