Yarn strength refers to the maximum force a yarn can withstand before breaking, while yarn tenacity measures this force relative to the yarn's linear density, indicating its efficiency and performance. Understanding the difference between these terms helps you select the appropriate yarn for durability and fabric quality in textile production.

Table of Comparison

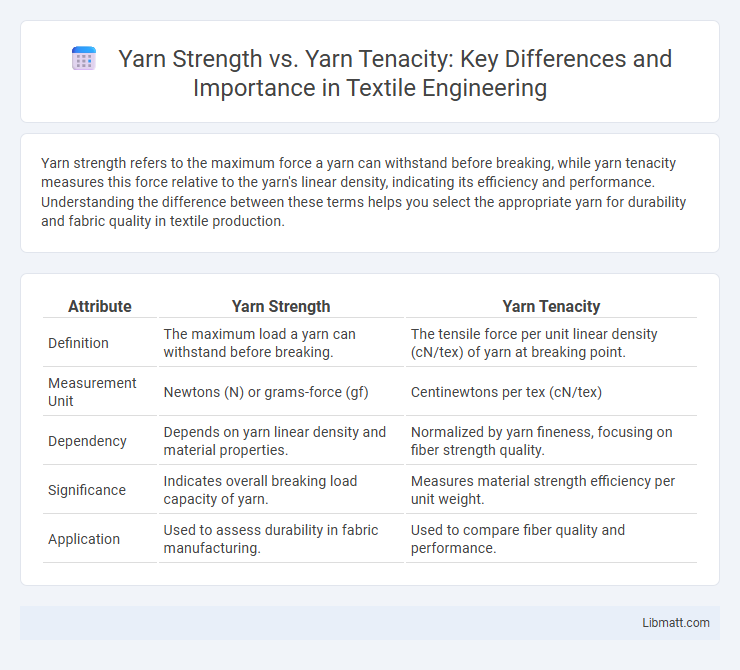

| Attribute | Yarn Strength | Yarn Tenacity |

|---|---|---|

| Definition | The maximum load a yarn can withstand before breaking. | The tensile force per unit linear density (cN/tex) of yarn at breaking point. |

| Measurement Unit | Newtons (N) or grams-force (gf) | Centinewtons per tex (cN/tex) |

| Dependency | Depends on yarn linear density and material properties. | Normalized by yarn fineness, focusing on fiber strength quality. |

| Significance | Indicates overall breaking load capacity of yarn. | Measures material strength efficiency per unit weight. |

| Application | Used to assess durability in fabric manufacturing. | Used to compare fiber quality and performance. |

Introduction to Yarn Strength and Tenacity

Yarn strength refers to the maximum load a yarn can withstand before breaking, typically measured in grams per denier or newtons. Yarn tenacity quantifies the strength relative to the yarn's linear density, providing a precise assessment of fiber performance in grams per tex or newtons per tex. Understanding the distinction between strength and tenacity is crucial for selecting materials suitable for specific textile applications and ensuring product durability.

Defining Yarn Strength

Yarn strength refers to the maximum load or force a yarn can withstand before breaking, measured in units such as newtons or grams-force. It is a critical parameter in textile manufacturing, indicating the durability and performance of the yarn under tensile stress. Unlike yarn tenacity, which normalizes strength by yarn linear density (typically expressed in centiNewtons per tex), yarn strength provides an absolute measure of the yarn's resistance to breakage.

Understanding Yarn Tenacity

Yarn tenacity measures the tensile strength of yarn relative to its linear density, expressed in grams per denier (gpd) or newtons per tex (N/tex), providing a critical indicator of yarn performance under stress. Unlike absolute yarn strength, tenacity accounts for yarn fineness, enabling comparison across different fiber types and yarn counts. Understanding yarn tenacity is essential for optimizing textile durability, fabric development, and quality control in industrial applications.

Key Differences Between Strength and Tenacity

Yarn strength measures the maximum load a yarn can withstand before breaking, while yarn tenacity refers to the strength per unit linear density, often expressed in grams per denier. Strength is an absolute value influenced by yarn size and structure, whereas tenacity provides a normalized measure of fiber quality by accounting for yarn fineness. Understanding this difference helps you optimize fabric performance and durability based on specific application requirements.

Measurement Methods for Yarn Strength

Yarn strength is typically measured using tensile testing machines that apply controlled force until the yarn breaks, providing values in grams force (gf) or Newtons (N). Yarn tenacity is calculated by dividing the yarn's breaking force by its linear density, commonly expressed in grams per tex (g/tex), highlighting the yarn's strength relative to its fineness. Accurate measurement requires standardized procedures such as ASTM D2256 or ISO 2062 to ensure consistent evaluation of tensile properties across different yarn types.

Measurement Methods for Yarn Tenacity

Yarn tenacity is measured by the maximum tensile force a yarn can withstand before breaking, typically expressed in grams per tex or cN/dtex, using instruments like the single fiber tensile tester or universal testing machines. Measurement methods involve clamping the yarn sample and applying a controlled tensile load until failure, with elongation and load data recorded to calculate tenacity accurately. Standardized test methods such as ASTM D2256 and ISO 2062 ensure consistent evaluation of yarn tenacity across different fiber types and production batches.

Factors Influencing Yarn Strength

Yarn strength is influenced by multiple factors including fiber type, fiber length, and yarn twist level, which directly affect the load-bearing capacity before breaking. Yarn tenacity, defined as the strength per unit linear density, depends significantly on the uniformity of fiber alignment and the presence of defects or weak points within the yarn structure. Environmental conditions such as humidity and processing techniques like spinning method also play critical roles in determining both yarn strength and tenacity.

Factors Affecting Yarn Tenacity

Yarn tenacity primarily depends on fiber properties, spinning methods, and yarn structure, with fiber length, fineness, and strength playing crucial roles. The tension during spinning, twist per inch, and yarn uniformity influence the ability of the yarn to withstand stress without breaking. Environmental factors such as humidity and temperature can alter fiber elasticity, thereby affecting the overall tenacity of the yarn.

Relevance in Textile Applications

Yarn strength and yarn tenacity are critical parameters in textile applications, directly influencing fabric durability and performance. Yarn strength measures the maximum load a yarn can withstand before breaking, while yarn tenacity relates this strength to the yarn's linear density, providing insight into material efficiency. Understanding these factors helps you select the appropriate yarn for high-stress applications such as upholstery, activewear, or industrial fabrics, ensuring product longevity and reliability.

Conclusion: Comparing Yarn Strength and Tenacity

Yarn strength measures the maximum force a yarn can withstand before breaking, whereas yarn tenacity expresses this strength relative to the yarn's linear density, typically in grams per denier. Comparing yarn strength and tenacity provides a clearer understanding of yarn performance by factoring in both absolute breaking force and yarn fineness. This comparison helps in selecting the appropriate yarn for specific textile applications, ensuring durability and efficiency.

Yarn Strength vs Yarn Tenacity Infographic

libmatt.com

libmatt.com