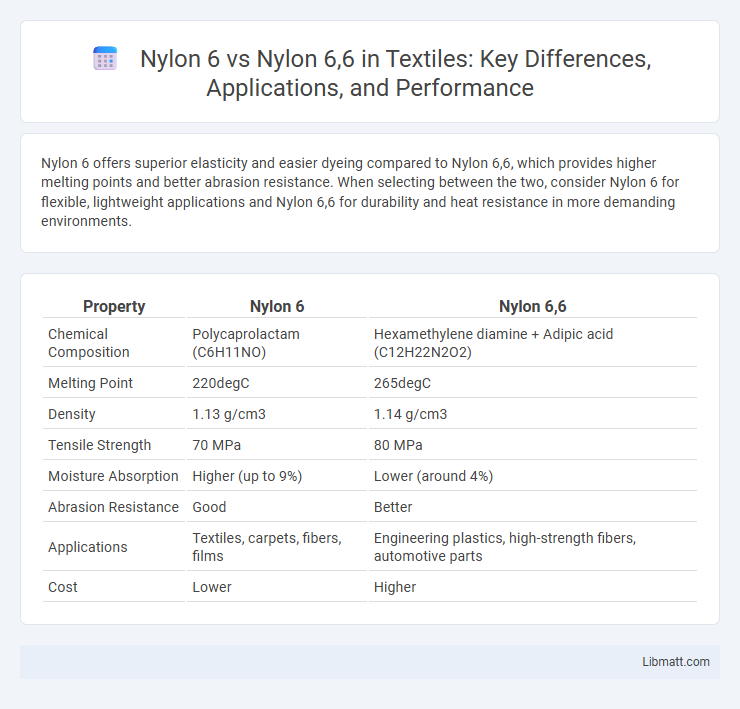

Nylon 6 offers superior elasticity and easier dyeing compared to Nylon 6,6, which provides higher melting points and better abrasion resistance. When selecting between the two, consider Nylon 6 for flexible, lightweight applications and Nylon 6,6 for durability and heat resistance in more demanding environments.

Table of Comparison

| Property | Nylon 6 | Nylon 6,6 |

|---|---|---|

| Chemical Composition | Polycaprolactam (C6H11NO) | Hexamethylene diamine + Adipic acid (C12H22N2O2) |

| Melting Point | 220degC | 265degC |

| Density | 1.13 g/cm3 | 1.14 g/cm3 |

| Tensile Strength | 70 MPa | 80 MPa |

| Moisture Absorption | Higher (up to 9%) | Lower (around 4%) |

| Abrasion Resistance | Good | Better |

| Applications | Textiles, carpets, fibers, films | Engineering plastics, high-strength fibers, automotive parts |

| Cost | Lower | Higher |

Introduction to Nylon 6 and Nylon 6,6

Nylon 6 and Nylon 6,6 are two common types of polyamides widely used in engineering plastics. Nylon 6 is produced from caprolactam through ring-opening polymerization, while Nylon 6,6 is synthesized from hexamethylene diamine and adipic acid via condensation polymerization. Your choice between these materials depends on desired properties such as tensile strength, heat resistance, and chemical durability, with Nylon 6,6 generally offering higher melting points and strength.

Chemical Structure Differences

Nylon 6 features a single type of monomer, caprolactam, resulting in a linear polymer chain with repeating units of six carbon atoms. Nylon 6,6 is composed of two monomers, hexamethylenediamine and adipic acid, creating a polymer with alternating amide groups and six carbon atoms in each repeating unit. Your choice between Nylon 6 and Nylon 6,6 depends on the specific chemical structure differences that impact properties like melting point, strength, and moisture absorption.

Manufacturing Processes Compared

Nylon 6 is produced through ring-opening polymerization of caprolactam, resulting in a simpler and more cost-effective manufacturing process compared to Nylon 6,6, which requires a polycondensation reaction between hexamethylene diamine and adipic acid. The production of Nylon 6 involves fewer steps and lower energy consumption, making it more efficient for large-scale manufacturing. Your decision between these materials should consider these process differences alongside performance characteristics for optimal application.

Mechanical Properties Analysis

Nylon 6 exhibits lower tensile strength and modulus compared to Nylon 6,6, making Nylon 6,6 more suitable for high-stress applications. The crystallinity of Nylon 6,6 enhances its mechanical properties, including superior abrasion resistance and higher melting temperature around 265degC. Nylon 6, with a melting point near 220degC, offers better impact resistance and flexibility but generally lower stiffness and mechanical endurance.

Thermal Resistance and Stability

Nylon 6,6 exhibits superior thermal resistance compared to Nylon 6, with a higher melting point around 265degC versus 220degC, making it more suitable for high-temperature applications. Its molecular structure provides enhanced thermal stability, reducing deformation under heat stress and extending the material's lifespan in demanding environments. Your choice between these polymers should consider the operational temperature requirements to ensure optimal performance and durability.

Moisture Absorption and Effects

Nylon 6 absorbs more moisture than Nylon 6,6, typically around 2.5% to 3% compared to 1.5% to 2% at equilibrium, impacting dimensional stability and mechanical properties. This higher moisture absorption in Nylon 6 leads to increased flexibility but can reduce tensile strength and stiffness over time. Understanding these differences is crucial for selecting the right material for applications where moisture exposure affects your product's performance.

Application Areas for Each Nylon

Nylon 6 is widely used in automotive parts, textiles, and packaging films due to its excellent elasticity, impact resistance, and easier processing compared to Nylon 6,6. Nylon 6,6 offers superior mechanical strength, thermal resistance, and durability, making it ideal for industrial applications such as electrical components, high-performance gears, and heavy-duty tire cords. Both materials serve distinct roles in engineering plastics, with Nylon 6 favored for flexible consumer products and Nylon 6,6 preferred in demanding structural and engineering applications.

Environmental Impact and Recyclability

Nylon 6 and Nylon 6,6 differ significantly in environmental impact and recyclability due to their chemical structures; Nylon 6 is made from caprolactam, which allows for more efficient chemical recycling processes, reducing waste and energy consumption. Nylon 6,6, composed of hexamethylenediamine and adipic acid, tends to have a higher carbon footprint because its production emits more greenhouse gases and utilizes more energy-intensive steps. Choosing Nylon 6 can enhance your sustainability efforts since it offers better recyclability options and a slightly lower environmental impact compared to Nylon 6,6.

Cost Considerations and Market Availability

Nylon 6 generally offers lower manufacturing costs and better market availability due to its simpler polymerization process and widespread production, making it a cost-effective choice for many applications. Nylon 6,6, although typically more expensive, provides superior mechanical properties and heat resistance, which justifies its higher price in performance-critical markets such as automotive and industrial manufacturing. Both polymers have well-established global supply chains, but Nylon 6's broader use in textiles and packaging contributes to its greater overall market presence and price competitiveness.

Which Nylon is Best for Your Needs?

Nylon 6 offers excellent flexibility, impact resistance, and faster drying times, making it ideal for applications requiring elasticity and toughness. Nylon 6,6 provides superior heat resistance, higher tensile strength, and better abrasion resistance, which suits demanding industrial or automotive uses. Evaluating your specific performance needs, such as durability versus flexibility, will help determine which nylon type best matches your project requirements.

Nylon 6 vs Nylon 6,6 Infographic

libmatt.com

libmatt.com