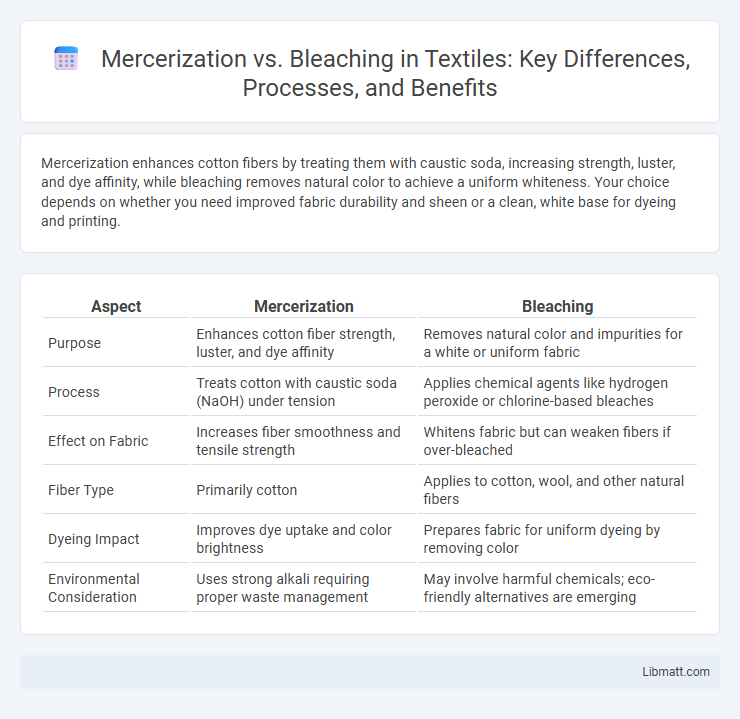

Mercerization enhances cotton fibers by treating them with caustic soda, increasing strength, luster, and dye affinity, while bleaching removes natural color to achieve a uniform whiteness. Your choice depends on whether you need improved fabric durability and sheen or a clean, white base for dyeing and printing.

Table of Comparison

| Aspect | Mercerization | Bleaching |

|---|---|---|

| Purpose | Enhances cotton fiber strength, luster, and dye affinity | Removes natural color and impurities for a white or uniform fabric |

| Process | Treats cotton with caustic soda (NaOH) under tension | Applies chemical agents like hydrogen peroxide or chlorine-based bleaches |

| Effect on Fabric | Increases fiber smoothness and tensile strength | Whitens fabric but can weaken fibers if over-bleached |

| Fiber Type | Primarily cotton | Applies to cotton, wool, and other natural fibers |

| Dyeing Impact | Improves dye uptake and color brightness | Prepares fabric for uniform dyeing by removing color |

| Environmental Consideration | Uses strong alkali requiring proper waste management | May involve harmful chemicals; eco-friendly alternatives are emerging |

Introduction to Mercerization and Bleaching

Mercerization is a chemical treatment process applied to cotton fibers involving sodium hydroxide, which enhances fiber strength, luster, and dye affinity. Bleaching, on the other hand, uses oxidizing agents like hydrogen peroxide or chlorine to remove natural color and impurities from fibers, resulting in a clean, white fabric. Both processes are essential in textile manufacturing to improve the quality and appearance of cotton products.

Definition and Purpose of Mercerization

Mercerization is a chemical treatment applied to cotton fibers to increase luster, strength, and affinity for dye, enhancing fabric quality and appearance. Unlike bleaching, which primarily removes natural color and impurities to brighten textiles, mercerization alters the fiber structure to improve durability and dye uptake. This process involves treating cotton with concentrated sodium hydroxide solution, resulting in smoother, more reflective fibers with superior dye retention.

Definition and Purpose of Bleaching

Bleaching is a chemical treatment process that removes natural color, impurities, and unwanted pigments from fibers or fabrics, primarily to achieve uniform whiteness and enhance dye uptake. This technique uses agents such as hydrogen peroxide or sodium hypochlorite to degrade colored substances without damaging the fiber's structure. By improving brightness and cleanliness, bleaching prepares textiles for subsequent processing stages like dyeing, printing, or finishing.

Key Chemical Processes Involved

Mercerization involves treating cotton fibers with a strong sodium hydroxide (NaOH) solution, causing fiber swelling, increased surface area, and enhanced luster and strength through structural rearrangement of cellulose. Bleaching employs oxidative chemicals such as hydrogen peroxide (H2O2) or sodium hypochlorite (NaClO) to break down colored impurities and natural pigments, resulting in a whitened fabric. Mercerization alters the cellulose crystalline structure to improve dye affinity, while bleaching chemically removes colorants without significantly changing fiber morphology.

Effects on Fiber Structure and Strength

Mercerization alters cotton fibers by causing swelling and increased crystallinity, which enhances fiber strength, luster, and dye affinity. In contrast, bleaching primarily removes natural pigments and impurities without significantly changing fiber morphology but can weaken fibers due to chemical degradation. Mercerized fibers exhibit greater tensile strength and durability compared to bleached fibers, making them more suitable for high-quality textile applications.

Differences in Appearance and Luster

Mercerization enhances the luster and smoothness of cotton fibers, resulting in a shiny, silky appearance that improves fabric dye affinity and strength. Bleaching removes natural pigments and impurities, producing a brighter, whiter fabric but can leave fibers dull and weakened. Your choice between mercerized or bleached fabrics depends on whether you prioritize sheen and texture or simply a cleaner, lighter look.

Environmental Impact and Sustainability

Mercerization uses caustic soda to enhance cotton's luster and dye affinity, but it generates alkaline wastewater requiring proper treatment to prevent environmental harm. Bleaching involves strong oxidizers like chlorine, which can release toxic byproducts affecting aquatic ecosystems and increasing chemical waste. Your choice between these processes should consider their sustainability profiles, with modern methods focusing on reducing chemical use and improving wastewater management to minimize environmental impact.

Common Applications in the Textile Industry

Mercerization enhances cotton fibers by increasing luster, strength, and dye affinity, making it ideal for high-quality garments, upholstery, and luxury textiles. Bleaching removes natural pigments and impurities, producing a uniform white base essential for printed fabrics, hosiery, and medical textiles. Your choice between mercerization and bleaching depends on the desired fabric finish and end-use requirements in the textile industry.

Cost Implications and Efficiency

Mercerization involves treating cotton fibers with sodium hydroxide, enhancing luster, strength, and dye affinity but incurs higher costs due to chemical usage and energy consumption compared to bleaching, which primarily removes impurities to improve whiteness at a lower expense. Bleaching processes typically offer faster throughput and lower operational costs, making them more efficient for large-scale production focused on fabric appearance rather than fiber properties. The cost efficiency of bleaching is offset by mercerization's added value in premium textiles where improved durability and dye uptake justify the investment.

Choosing Between Mercerization and Bleaching

Choosing between mercerization and bleaching depends on the desired fabric characteristics and end-use. Mercerization enhances cotton's strength, luster, and dye affinity, making it ideal for high-quality textiles requiring durability and vivid colors. Bleaching, on the other hand, removes natural pigments to achieve whiteness and softness, suitable for fabrics that prioritize a clean, bright appearance.

Mercerization vs Bleaching Infographic

libmatt.com

libmatt.com