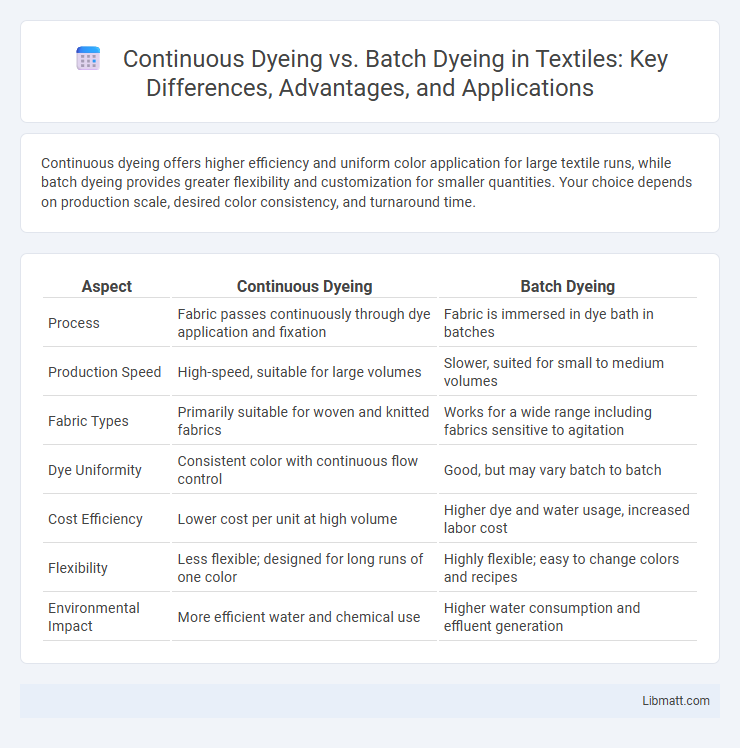

Continuous dyeing offers higher efficiency and uniform color application for large textile runs, while batch dyeing provides greater flexibility and customization for smaller quantities. Your choice depends on production scale, desired color consistency, and turnaround time.

Table of Comparison

| Aspect | Continuous Dyeing | Batch Dyeing |

|---|---|---|

| Process | Fabric passes continuously through dye application and fixation | Fabric is immersed in dye bath in batches |

| Production Speed | High-speed, suitable for large volumes | Slower, suited for small to medium volumes |

| Fabric Types | Primarily suitable for woven and knitted fabrics | Works for a wide range including fabrics sensitive to agitation |

| Dye Uniformity | Consistent color with continuous flow control | Good, but may vary batch to batch |

| Cost Efficiency | Lower cost per unit at high volume | Higher dye and water usage, increased labor cost |

| Flexibility | Less flexible; designed for long runs of one color | Highly flexible; easy to change colors and recipes |

| Environmental Impact | More efficient water and chemical use | Higher water consumption and effluent generation |

Introduction to Continuous and Batch Dyeing

Continuous dyeing and batch dyeing represent two fundamental methods for imparting color to textiles with distinct operational efficiencies and applications. Continuous dyeing processes involve moving fabric continuously through dye baths and drying units, optimizing production for large volumes with consistent color application. Batch dyeing treats textile fibers in fixed quantities, allowing precise color control and flexibility suitable for varied material types and smaller production runs, making it essential to choose the right method based on your fabric's requirements and production scale.

Overview of Dyeing Processes

Continuous dyeing involves fabric moving steadily through a series of dye baths and fixation stages, enabling high-speed production with consistent color quality ideal for large volumes. Batch dyeing, on the other hand, processes fabric or yarn in discrete quantities within dyeing machines, allowing flexibility in color choice and better control over complex patterns. Your selection between these processes depends on factors like production scale, fabric type, and design requirements.

Equipment Used in Continuous and Batch Dyeing

Continuous dyeing utilizes advanced machines such as padder, stenter, and tenter frames, designed for high-speed fabric processing and uniform color application. Batch dyeing relies on equipment like jet dyeing machines, jiggers, and winches, which are ideal for smaller production volumes and diverse fabric types. Selecting the right equipment impacts your dyeing efficiency, fabric quality, and production scalability.

Process Workflow: Step-by-Step Comparison

Continuous dyeing involves fabric moving through a series of controlled stages, including pre-treatment, dye application, fixation, washing, and drying, allowing for uninterrupted processing of large fabric rolls. Batch dyeing processes fabric or yarn in discrete lots within dyeing vessels, where steps like loading, dyeing, rinsing, and unloading occur sequentially, making it suitable for small production runs or specialized colors. The continuous method emphasizes speed and uniformity, while batch dyeing offers flexibility and precise color control through repetitive cycles.

Fabric Suitability and End-Use Applications

Continuous dyeing is ideal for lightweight, uniform fabrics such as knits and woven textiles, offering high-speed production for large volumes used in apparel and home textiles. Batch dyeing suits heavier or delicate fabrics like upholstery and technical textiles, allowing precise color matching and quality control for fashion and industrial applications. Your choice depends on fabric type and end-use requirements, balancing efficiency with customization needs.

Efficiency and Production Output

Continuous dyeing offers higher efficiency and production output due to its uninterrupted process, allowing large volumes of fabric to be dyed rapidly with consistent quality. Batch dyeing, while flexible for smaller quantities and varied color requirements, involves more downtime between cycles, reducing overall throughput. Your choice should consider production scale and the need for speed versus customization in dyeing operations.

Color Consistency and Quality Control

Continuous dyeing offers superior color consistency by maintaining a steady flow of fabric through the dyeing process, ensuring uniform absorption of dye molecules and reducing color variation. Batch dyeing, while flexible for smaller runs, often faces challenges in quality control due to inconsistencies in dye liquor concentration and temperature fluctuations between batches. Your choice between these methods directly impacts the precision of color matching and overall fabric quality in textile manufacturing.

Environmental Impact and Resource Consumption

Continuous dyeing significantly reduces water usage and energy consumption compared to batch dyeing due to its efficient process flow and lower liquor ratios. Batch dyeing generates higher effluent volumes with concentrated chemical loads, leading to increased wastewater treatment challenges and environmental pollution. The reduced processing time and chemical use in continuous dyeing contribute to a smaller carbon footprint and enhanced sustainability in textile manufacturing.

Cost Analysis: Operational and Investment Aspects

Continuous dyeing offers lower operational costs due to higher throughput and reduced labor intensity compared to batch dyeing, which requires frequent setup changes and longer processing times. Investment costs for continuous dyeing machinery are significantly higher but justified by economies of scale in large production volumes, while batch dyeing equipment involves lower initial capital expenditure and greater flexibility for smaller runs. The choice between continuous and batch dyeing depends on production scale, with continuous dyeing favored for high-volume, uniform products, and batch dyeing preferred for diverse or custom fabric batches.

Choosing the Right Dyeing Method: Key Considerations

Selecting the appropriate dyeing method depends on fabric type, production volume, and color consistency requirements. Continuous dyeing offers high efficiency and uniformity for large-scale production of synthetic fabrics, while batch dyeing provides flexibility and cost-effectiveness for small runs and natural fibers. Evaluating factors such as resource availability, environmental impact, and desired colorfastness ensures optimal results tailored to specific textile applications.

Continuous dyeing vs Batch dyeing Infographic

libmatt.com

libmatt.com