Water jet looms use high-pressure water to propel the weft yarn through the warp shed, offering faster weaving speeds and energy efficiency for synthetic fibers. Projectile looms, on the other hand, employ a small projectile to carry the weft thread, providing higher fabric quality and greater versatility for heavier or coarser materials.

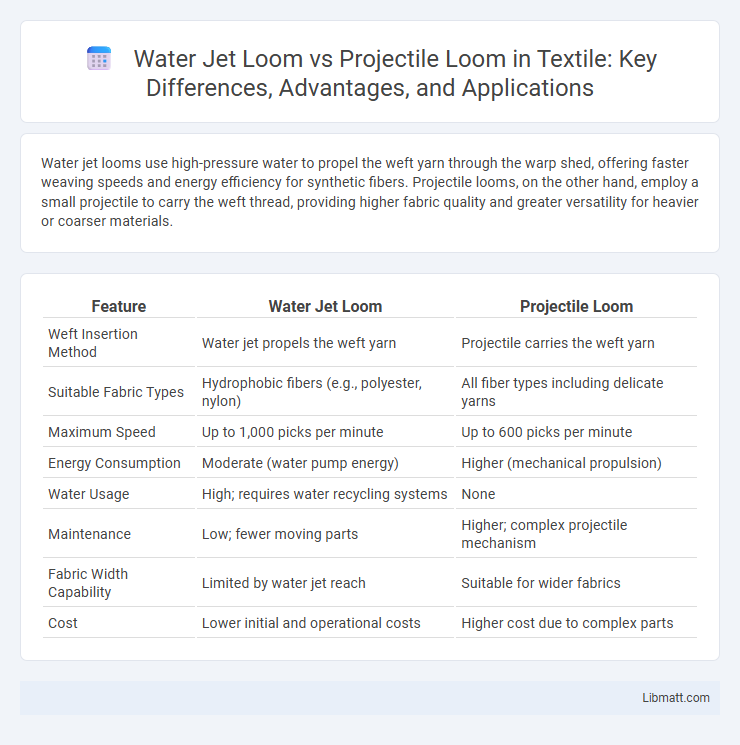

Table of Comparison

| Feature | Water Jet Loom | Projectile Loom |

|---|---|---|

| Weft Insertion Method | Water jet propels the weft yarn | Projectile carries the weft yarn |

| Suitable Fabric Types | Hydrophobic fibers (e.g., polyester, nylon) | All fiber types including delicate yarns |

| Maximum Speed | Up to 1,000 picks per minute | Up to 600 picks per minute |

| Energy Consumption | Moderate (water pump energy) | Higher (mechanical propulsion) |

| Water Usage | High; requires water recycling systems | None |

| Maintenance | Low; fewer moving parts | Higher; complex projectile mechanism |

| Fabric Width Capability | Limited by water jet reach | Suitable for wider fabrics |

| Cost | Lower initial and operational costs | Higher cost due to complex parts |

Introduction to Water Jet Looms and Projectile Looms

Water jet looms use high-pressure water streams to propel the weft yarn through the warp shed, making them ideal for weaving hydrophobic fibers like polyester. Projectile looms employ small, bullet-shaped projectiles to carry the weft yarn across, offering superior performance with heavy, coarse, or textured yarns. Both looms are widely used in textile manufacturing for rapid, efficient weaving but differ significantly in energy consumption and fabric compatibility.

Working Principles of Water Jet Looms

Water jet looms operate by propelling a fine jet of water through the shed to carry the weft yarn across the warp threads, offering precise and high-speed fabric weaving suitable for synthetic fibers. The weaving process involves generating a controlled water pressure that propels the yarn without friction, reducing yarn breakage and increasing productivity. Understanding your fabric types and production needs helps determine if the water jet loom's efficient and smooth weft insertion matches your manufacturing requirements.

Working Principles of Projectile Looms

Projectile looms operate by using small, bullet-shaped projectiles to carry the weft yarn through the warp shed, propelled across the loom by a high-speed mechanism. These projectiles grip the weft yarn securely, allowing for precise and rapid insertion without tension disruptions, making them ideal for heavy or dense fabrics. Your choice of a projectile loom can enhance weaving efficiency and fabric quality when handling thicker or coarser materials.

Key Differences Between Water Jet and Projectile Looms

Water jet looms use high-pressure water to propel the weft yarn through the warp shed, making them ideal for weaving hydrophilic fibers like cotton and polyester, whereas projectile looms use a small gripper or projectile to carry the weft yarn, suitable for a wide range of yarn types including heavy and textured yarns. Water jet looms offer faster weaving speeds and lower energy consumption but are limited by the need for water-compatible yarns, while projectile looms provide greater versatility and improved fabric quality at higher operating costs. Understanding these differences helps you select the best loom for specific fabric requirements and production efficiency.

Material Compatibility and Applications

Water jet looms are primarily compatible with hydrophobic synthetic fibers such as polyester and nylon due to their reliance on water as the weft insertion medium, making them ideal for producing lightweight, breathable fabrics used in sportswear and technical textiles. Projectile looms handle a broader range of materials, including heavy and delicate fabrics like wool, cotton, and blended textiles, because they utilize mechanical projectiles to insert the weft yarn without water, allowing for diverse applications in upholstery, denim, and industrial textiles. The choice between these looms depends on fabric weight, moisture sensitivity, and end-use requirements, with water jet looms excelling in fast, efficient production of synthetic textiles, while projectile looms offer versatility for thicker, multi-fiber materials.

Efficiency and Production Speed Comparison

Water jet looms offer high-speed weaving with efficiency rates up to 1100 picks per minute, making them ideal for lightweight synthetic fabrics. Projectile looms operate at slower speeds, typically around 400-600 picks per minute, but excel in weaving heavier and more diverse materials due to their robust projectile insertion method. Your choice depends on balancing the faster production speeds of water jet looms against the versatility and fabric compatibility offered by projectile looms.

Energy Consumption and Operating Costs

Water jet looms consume significantly less energy compared to projectile looms due to their efficient use of high-pressure water jets for weft insertion, resulting in lower operating costs. Projectile looms require more power to propel the projectile carrying the weft yarn, increasing energy consumption and maintenance expenses. If you prioritize reducing your textile production energy footprint, a water jet loom offers a more cost-effective solution.

Fabric Quality and Weaving Performance

Water jet looms produce fabrics with smoother surfaces and higher dimensional stability due to precise water jet insertion, ideal for lightweight and synthetic materials. Projectile looms, known for high shedding and picking efficiency, excel in weaving heavy, complex fabrics with superior edge strength and fewer defects. Weaving performance in projectile looms typically surpasses water jet looms in terms of versatility and fabric density, while water jet looms offer faster production rates for specific fabric types.

Maintenance and Operational Challenges

Water jet looms require frequent maintenance of water pressure systems and filtration units to prevent clogging and ensure consistent jet performance, posing challenges in areas with hard water. Projectile looms experience higher wear on mechanical components such as projectiles and guide bars, necessitating regular inspection and replacement to avoid operational downtime. Both loom types demand specialized knowledge for troubleshooting, but water jet looms typically incur higher water consumption costs while projectile looms face challenges related to projectile damage and lint accumulation.

Choosing the Right Loom for Textile Manufacturing

Water jet looms offer high-speed weaving with reduced energy consumption and are ideal for fine synthetic fabrics, while projectile looms excel in versatility, handling heavy and diverse yarn types efficiently. Your choice depends on the fabric type, production speed, and material compatibility, as water jet looms suit lightweight blends and projectile looms accommodate thicker, more varied textiles. Evaluating operational costs and maintenance requirements ensures selecting the right loom aligns with your manufacturing goals.

Water jet loom vs Projectile loom Infographic

libmatt.com

libmatt.com