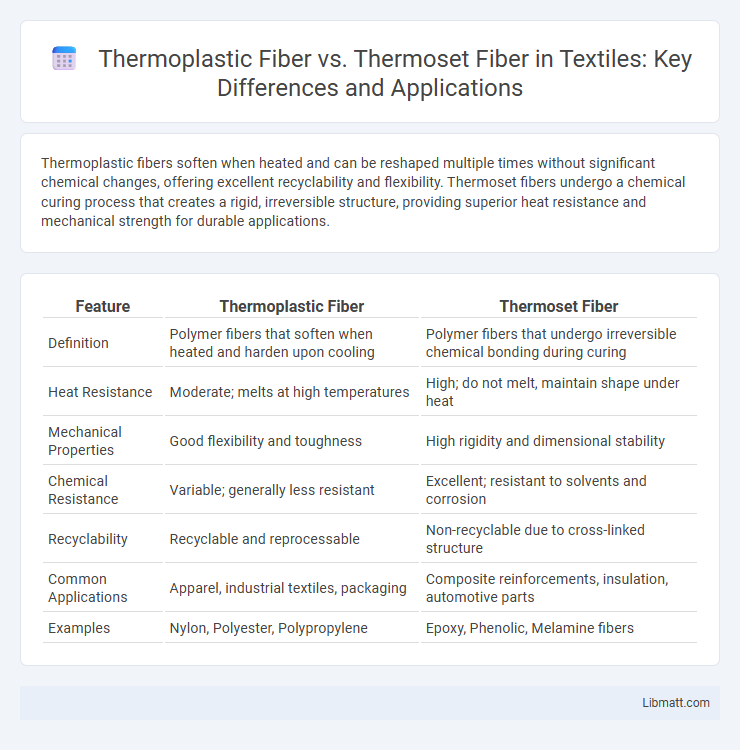

Thermoplastic fibers soften when heated and can be reshaped multiple times without significant chemical changes, offering excellent recyclability and flexibility. Thermoset fibers undergo a chemical curing process that creates a rigid, irreversible structure, providing superior heat resistance and mechanical strength for durable applications.

Table of Comparison

| Feature | Thermoplastic Fiber | Thermoset Fiber |

|---|---|---|

| Definition | Polymer fibers that soften when heated and harden upon cooling | Polymer fibers that undergo irreversible chemical bonding during curing |

| Heat Resistance | Moderate; melts at high temperatures | High; do not melt, maintain shape under heat |

| Mechanical Properties | Good flexibility and toughness | High rigidity and dimensional stability |

| Chemical Resistance | Variable; generally less resistant | Excellent; resistant to solvents and corrosion |

| Recyclability | Recyclable and reprocessable | Non-recyclable due to cross-linked structure |

| Common Applications | Apparel, industrial textiles, packaging | Composite reinforcements, insulation, automotive parts |

| Examples | Nylon, Polyester, Polypropylene | Epoxy, Phenolic, Melamine fibers |

Introduction to Thermoplastic and Thermoset Fibers

Thermoplastic fibers are polymers that soften when heated and solidify upon cooling, enabling easy reshaping and recycling, commonly used in applications requiring flexibility and impact resistance. Thermoset fibers, in contrast, undergo an irreversible curing process that forms a rigid, heat-resistant network, ideal for high-strength composites in automotive and aerospace industries. Understanding the molecular structure differences between thermoplastic and thermoset fibers is crucial for selecting materials based on mechanical performance and thermal stability.

Chemical Structure and Composition

Thermoplastic fibers consist of linear or slightly branched polymer chains that can melt and be reshaped repeatedly due to their non-crosslinked structure. Thermoset fibers feature heavily crosslinked polymer networks, providing rigidity and thermal stability but preventing them from melting or reshaping after curing. Understanding the chemical structure differences helps you select the appropriate fiber type for applications requiring flexibility or high thermal resistance.

Manufacturing Processes

Thermoplastic fibers are produced through melting and solidifying processes, allowing for easy reshaping and recycling during manufacturing. Thermoset fibers undergo chemical curing reactions that create irreversible cross-linked structures, providing high thermal stability but limiting post-processing flexibility. Manufacturing thermoset fibers typically involves molding or casting, contrasting with the extrusion and drawing commonly used for thermoplastic fibers.

Mechanical Properties Comparison

Thermoplastic fibers exhibit higher impact resistance and greater flexibility due to their ability to undergo plastic deformation, while thermoset fibers provide superior thermal stability and stiffness because of their cross-linked molecular structure. Your choice between thermoplastic and thermoset fibers depends on the specific mechanical property requirements of your application, such as the need for toughness versus rigidity. Thermoset fibers typically maintain strength at elevated temperatures better than thermoplastic fibers, making them ideal for high-performance composites.

Thermal Stability and Performance

Thermoplastic fibers exhibit high thermal stability with the ability to soften and remold upon heating, making them ideal for applications requiring flexibility and recyclability under elevated temperatures. Thermoset fibers provide superior thermal performance with strong heat resistance and dimensional stability due to their cross-linked polymer structure, which does not soften when exposed to heat. Your choice depends on whether you prioritize reusability and moldability (thermoplastics) or enhanced heat durability and mechanical strength (thermosets).

Processing and Fabrication Techniques

Thermoplastic fibers can be processed using melting and reshaping techniques such as extrusion, injection molding, and thermoforming, allowing for recycling and reshaping after initial fabrication. Thermoset fibers require curing through heat or chemical agents, forming irreversible cross-linked structures that provide high thermal stability but limit recyclability and reshaping options. Your choice between these fibers depends on the desired manufacturing flexibility and end-use durability requirements.

Recyclability and Environmental Impact

Thermoplastic fibers offer superior recyclability due to their ability to be melted and reshaped multiple times without significant degradation, reducing waste and environmental burden. In contrast, thermoset fibers are chemically crosslinked and cannot be remelted, resulting in limited recyclability and greater environmental impact through landfill accumulation or incineration. The recycling efficiency of thermoplastic fibers supports circular economy initiatives, making them more sustainable for industries aiming to minimize ecological footprints.

Common Applications and Industries

Thermoplastic fibers are widely used in automotive parts, packaging, and consumer goods due to their flexibility, recyclability, and rapid processing times. Thermoset fibers find common applications in aerospace, construction, and electronics industries, where enhanced heat resistance, structural durability, and chemical stability are essential. Understanding the specific requirements of your industry helps determine whether thermoplastic or thermoset fibers best optimize performance and longevity.

Cost Analysis and Market Trends

Thermoplastic fibers generally offer lower production costs due to their recyclability and faster processing times compared to thermoset fibers, which require more energy-intensive curing processes. Market trends indicate increasing demand for thermoplastic fibers in automotive and aerospace industries driven by sustainability goals and cost efficiency, while thermoset fibers maintain a strong presence in high-performance applications due to superior heat resistance and mechanical properties. Your choice between these fibers should consider cost-effectiveness aligned with specific application requirements and evolving industry standards.

Future Developments in Fiber Technology

Future developments in fiber technology emphasize enhanced performance and sustainability of thermoplastic fibers, including improved recyclability, increased strength-to-weight ratios, and faster processing times compared to thermoset fibers. Innovations in composite materials leverage thermoplastic fibers for their ability to be remolded and repaired, reducing environmental impact and production costs. Emerging applications in aerospace, automotive, and renewable energy sectors drive research towards hybrid fibers that combine the durability of thermoset fibers with the versatility of thermoplastics.

Thermoplastic fiber vs Thermoset fiber Infographic

libmatt.com

libmatt.com