RFD fabric is ready-for-dyeing, meaning it has been pre-washed to remove impurities without any color, allowing for easier customization in your projects. Greige fabric, on the other hand, is raw, unprocessed textile straight from the loom that requires additional finishing before it can be dyed or used in garment production.

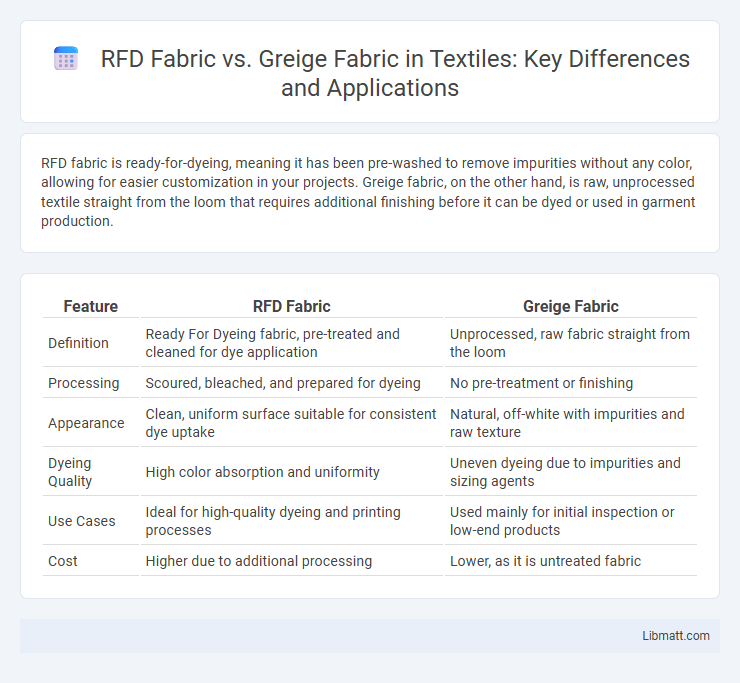

Table of Comparison

| Feature | RFD Fabric | Greige Fabric |

|---|---|---|

| Definition | Ready For Dyeing fabric, pre-treated and cleaned for dye application | Unprocessed, raw fabric straight from the loom |

| Processing | Scoured, bleached, and prepared for dyeing | No pre-treatment or finishing |

| Appearance | Clean, uniform surface suitable for consistent dye uptake | Natural, off-white with impurities and raw texture |

| Dyeing Quality | High color absorption and uniformity | Uneven dyeing due to impurities and sizing agents |

| Use Cases | Ideal for high-quality dyeing and printing processes | Used mainly for initial inspection or low-end products |

| Cost | Higher due to additional processing | Lower, as it is untreated fabric |

Introduction to RFD Fabric and Greige Fabric

RFD fabric, or Ready-for-Dye fabric, undergoes minimal finishing processes, making it ideal for custom dyeing and printing to achieve specific color requirements. Greige fabric, also known as grey or greyish fabric, is the raw, unprocessed textile straight from the loom, lacking any finishing, bleaching, or dyeing treatments. Your choice between RFD and greige fabrics depends on the level of preparation needed for subsequent processing and the desired quality for final production.

Defining RFD Fabric: Characteristics & Uses

RFD fabric, known as "Ready for Dye" fabric, is a type of textile that has been fully processed through spinning, weaving, and finishing but remains undyed, offering a clean and uniform base ideal for customization. Compared to greige fabric, which is raw, unprocessed, and often contains impurities from the manufacturing process, RFD fabric provides better durability, consistent texture, and higher quality for printing and dyeing applications. Your choice of RFD fabric ensures more predictable color results and improved fabric performance in fashion, upholstery, and other textile industries.

What is Greige Fabric? Key Features Explained

Greige fabric is unprocessed textile material that has not undergone dyeing, bleaching, or finishing, preserving its raw and natural state. Key features of greige fabric include its versatility for further customization, cost-effectiveness, and the ability to evaluate fabric quality before finishing treatments. Your choice between RFD fabric and greige fabric depends on whether you prefer ready-to-dye material or fabric requiring additional processing.

Manufacturing Process: RFD vs Greige

RFD (Ready for Dye) fabric undergoes preliminary processing such as desizing, scouring, and bleaching to remove impurities, making it prepared for subsequent dyeing or printing. In contrast, Greige fabric is in its raw, unprocessed state, straight from the loom without any chemical treatments or finishing. The manufacturing process of RFD fabric ensures enhanced fabric quality and dye absorption, while Greige fabric requires additional processing before use in textile production.

Differences in Appearance and Texture

RFD fabric, meaning Ready For Dye, exhibits a softer texture and a cleaner, more polished appearance compared to Greige fabric, which is unprocessed and often features a rougher, coarser surface with visible weaving inconsistencies. The RFD treatment removes natural impurities and tightens the weave, resulting in a smoother finish and enhanced color absorption during dyeing. Greige fabric maintains a raw, natural look with its undyed and untreated fibers, offering a stiffer texture that may vary in uniformity.

Applications in the Textile Industry

RFD fabric, or Ready For Dyeing fabric, is primarily used in applications where customization and vibrant color finishes are essential, such as in fashion apparel and home textiles. Greige fabric, being in its unprocessed and undyed form, finds applications in industrial textiles, upholstery, and as a base for further finishing processes like bleaching or dyeing. Understanding the differences between RFD and Greige fabrics helps you select the right material for textile manufacturing, ensuring optimal performance and aesthetic appeal in final products.

Environmental Impact: RFD vs Greige Fabric

RFD (Ready for Dye) fabric undergoes minimal chemical processing compared to greige fabric, resulting in a lower environmental footprint due to reduced wastewater and chemical usage. Greige fabric, being untreated and unbleached, requires extensive wet processing that consumes more water, energy, and chemicals, increasing its overall environmental impact. Choosing RFD fabric supports sustainable textile production by minimizing pollution and resource consumption in the dyeing and finishing stages.

Cost Comparison: RFD Fabric vs Greige Fabric

RFD fabric, or Ready For Dye fabric, generally incurs higher costs compared to greige fabric due to added processing such as scouring and bleaching that prepare it for immediate dyeing. Greige fabric, being in its raw, unprocessed state directly from the loom, offers a lower price point but requires further treatment before dyeing or finishing. Manufacturers often choose greige fabric to minimize upfront costs, while RFD fabric is preferred for time-sensitive production that demands faster turnaround times.

Advantages and Disadvantages of Each Fabric

RFD fabric, or Ready-for-Dye fabric, offers the advantage of consistent color absorption and ease of customization, making it ideal for achieving vibrant, uniform shades, but it may exhibit higher production costs and environmental impact due to chemical treatments. Greige fabric, being untreated and unprocessed, provides maximum versatility for various finishes and lower initial costs, yet it requires additional processing before use, which can delay production timelines and potentially increase long-term expenses. Your choice between RFD and Greige fabric depends on balancing the need for immediate usability and color precision against budget and environmental considerations.

Which Fabric Should You Choose?

RFD fabric, or Ready For Dye fabric, offers a smooth, pre-treated surface ideal for vibrant, consistent coloring, while Greige fabric is unfinished and requires multiple processing steps before use. You should choose RFD fabric if your project demands high-quality dye absorption and minimal preparation time. Greige fabric suits applications where customization and cost-effectiveness are priorities, as it allows for greater flexibility in finishing processes.

RFD fabric vs Greige fabric Infographic

libmatt.com

libmatt.com