Melt spinning produces fibers by melting polymers and extruding them through a spinneret, resulting in cost-effective, high-speed fiber formation ideal for synthetic materials like polyester. Gel spinning involves extruding a polymer solution in a gel state, yielding ultra-strong, highly oriented fibers such as ultra-high-molecular-weight polyethylene, making it suitable when superior mechanical properties are required for your applications.

Table of Comparison

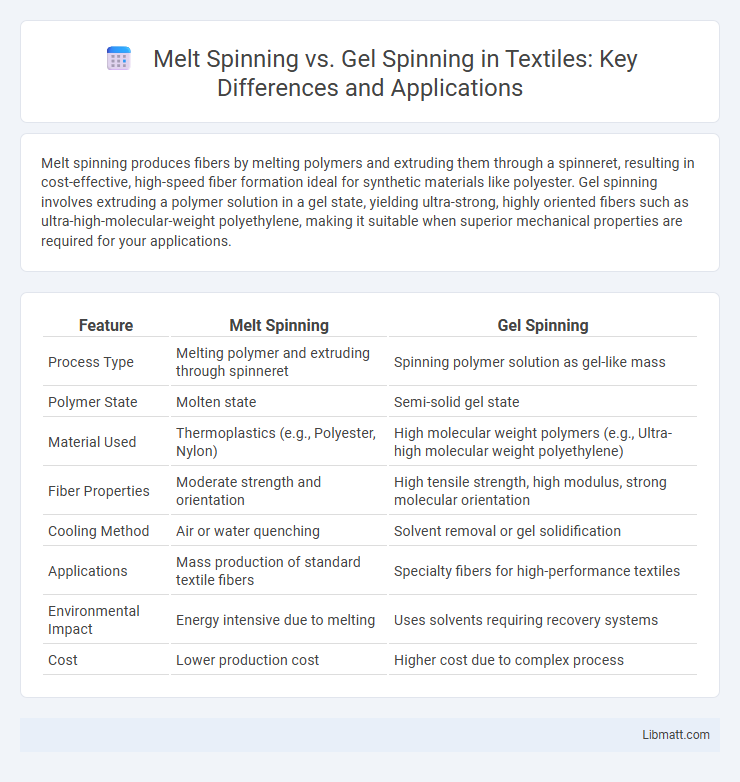

| Feature | Melt Spinning | Gel Spinning |

|---|---|---|

| Process Type | Melting polymer and extruding through spinneret | Spinning polymer solution as gel-like mass |

| Polymer State | Molten state | Semi-solid gel state |

| Material Used | Thermoplastics (e.g., Polyester, Nylon) | High molecular weight polymers (e.g., Ultra-high molecular weight polyethylene) |

| Fiber Properties | Moderate strength and orientation | High tensile strength, high modulus, strong molecular orientation |

| Cooling Method | Air or water quenching | Solvent removal or gel solidification |

| Applications | Mass production of standard textile fibers | Specialty fibers for high-performance textiles |

| Environmental Impact | Energy intensive due to melting | Uses solvents requiring recovery systems |

| Cost | Lower production cost | Higher cost due to complex process |

Introduction to Melt Spinning and Gel Spinning

Melt spinning involves melting a polymer and extruding it through a spinneret to form fibers rapidly cooled to solidify. Gel spinning uses a polymer solution or gel, producing highly oriented and stronger fibers due to controlled cooling and stretching. Your choice between these methods depends on the desired fiber properties and application requirements.

Understanding the Spinning Processes

Melt spinning involves melting polymer pellets and extruding the molten polymer through spinnerets to form continuous fibers rapidly cooled and solidified upon exiting. Gel spinning, by contrast, processes polymer solutions at lower temperatures, where fibers are formed as semi-solid gels, resulting in higher molecular orientation and enhanced mechanical properties. The key difference lies in the phase of the polymer during spinning, affecting fiber strength, processing conditions, and end-use performance.

Raw Materials Used in Melt and Gel Spinning

Melt spinning primarily utilizes thermoplastic polymers such as polyester, nylon, and polypropylene, which are melted and extruded through spinnerets to form fibers. Gel spinning employs high molecular weight polymers like ultra-high-molecular-weight polyethylene (UHMWPE) dissolved in solvents to create a gel state before fiber formation, enabling superior strength and molecular alignment. Your choice of raw material directly impacts fiber properties such as tensile strength, flexibility, and application suitability in melt versus gel spinning processes.

Key Differences Between Melt Spinning and Gel Spinning

Melt spinning involves melting a polymer resin and extruding it through spinnerets to form fibers, while gel spinning dissolves the polymer in a solvent forming a gel before extrusion. Melt spinning is faster and suitable for thermoplastics like polypropylene, whereas gel spinning produces higher strength fibers such as Ultra-High Molecular Weight Polyethylene (UHMWPE) due to better molecular alignment. The structural differences result in superior tensile strength and modulus in gel-spun fibers compared to melt-spun fibers.

Process Parameters and Operating Conditions

Melt spinning involves extruding molten polymer through a spinneret at temperatures typically between 200-300degC, with spinning speeds ranging from 500 to 2000 meters per minute, requiring precise control of cooling rates and take-up speeds to optimize fiber crystallinity and strength. Gel spinning operates by extruding a polymer solution or gel at lower temperatures, often below the polymer melting point, with controlled solvent evaporation and stretching ratios exceeding 20 times to achieve ultra-high molecular orientation and tensile strength. Process parameters such as solvent concentration, gelation temperature, and drawing speed critically influence gel spinning outcomes, while melt spinning depends heavily on melting temperature, extrusion pressure, and quenching conditions.

Advantages of Melt Spinning

Melt spinning offers significant advantages including higher production speeds and cost-effectiveness due to the elimination of solvents. This process enables the production of fibers with uniform diameters and enhanced strength, suitable for industrial-scale manufacturing. Melt spinning also allows for easier control over fiber properties such as crystallinity and orientation, contributing to consistent quality in textiles and composites.

Benefits of Gel Spinning

Gel spinning offers superior fiber strength and high tensile properties by producing ultra-high molecular weight polyethylene fibers with minimal defects. Its low-temperature process preserves polymer integrity, resulting in enhanced durability and flexibility compared to melt spinning. You can achieve finer, lightweight, and more resilient fibers ideal for advanced applications like medical sutures and ballistic materials.

Typical Applications for Melt and Gel Spinning

Melt spinning is commonly used for producing synthetic fibers such as polyester, nylon, and polypropylene, which are integral to textiles, automotive components, and packaging materials. Gel spinning is primarily employed to create high-performance fibers like ultra-high-molecular-weight polyethylene (UHMWPE), utilized in applications requiring exceptional strength and durability, including bulletproof vests, medical sutures, and high-strength ropes. The distinct fiber properties achieved through these spinning methods determine their suitability across diverse industrial and commercial applications.

Fiber Properties: Strength, Density, and Performance

Melt spinning produces fibers with moderate strength and density, optimized for cost-effective manufacturing and good durability in everyday applications. Gel spinning creates ultra-high-strength fibers characterized by exceptional tensile strength and low density, enhancing performance in high-stress environments like ballistic protection and medical sutures. Your choice between melt spinning and gel spinning impacts the fiber's mechanical properties, influencing its suitability for specialized technical applications.

Environmental Impact and Sustainability Considerations

Gel spinning produces fibers with lower environmental impact due to reduced energy consumption and fewer harmful emissions compared to melt spinning, which requires higher temperatures and greater energy input. Melt spinning often involves the use of petrochemical-based polymers, contributing to non-biodegradable waste, whereas gel spinning can utilize more sustainable or bio-based polymers, enhancing material recyclability. Your choice between these methods can significantly influence the sustainability profile of the produced fibers and overall ecological footprint.

Melt spinning vs Gel spinning Infographic

libmatt.com

libmatt.com