Loose pick allows strings to ring freely for a more fluid and dynamic sound, often used in genres like blues and rock, while tight pick involves precise, controlled string contact to create sharper, cleaner tones favored in styles such as jazz and metal. Your choice between loose and tight pick techniques can significantly impact the articulation and expression of your guitar playing.

Table of Comparison

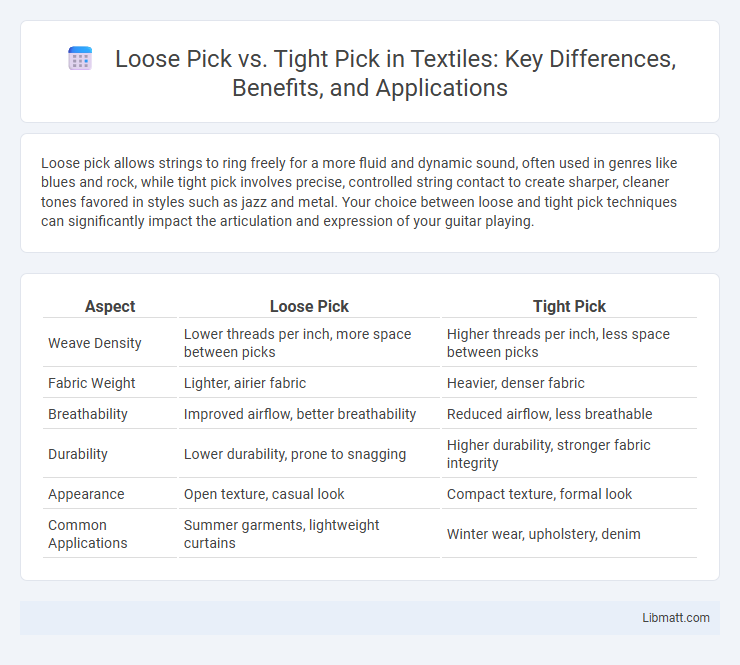

| Aspect | Loose Pick | Tight Pick |

|---|---|---|

| Weave Density | Lower threads per inch, more space between picks | Higher threads per inch, less space between picks |

| Fabric Weight | Lighter, airier fabric | Heavier, denser fabric |

| Breathability | Improved airflow, better breathability | Reduced airflow, less breathable |

| Durability | Lower durability, prone to snagging | Higher durability, stronger fabric integrity |

| Appearance | Open texture, casual look | Compact texture, formal look |

| Common Applications | Summer garments, lightweight curtains | Winter wear, upholstery, denim |

Understanding Loose Pick and Tight Pick

Loose pick refers to a weaving technique where the weft threads are spaced further apart, resulting in a fabric with increased airflow and a lighter texture. Tight pick involves closely packed weft threads, creating a denser, more durable fabric often used for upholstery or heavy-duty applications. Understanding the difference helps you select the right fabric texture and strength for your specific project needs.

Key Differences Between Loose Pick and Tight Pick

Loose pick features longer pick attack angles and more string contact, producing a warmer, more textured sound with greater dynamic variability. Tight pick involves shorter, precise picking angles with minimal string contact, delivering a brighter, cleaner tone and enhanced control for fast, articulate playing. Differences in pick grip tension, pick attack speed, and string contact directly affect tonal characteristics and playing styles in both techniques.

Advantages of Loose Pick

Loose pick offers greater speed and fluidity in guitar playing by allowing more wrist and finger movement, which helps you achieve faster alternate picking. It provides increased flexibility and a lighter touch, reducing fatigue during extended playing sessions. This technique is especially beneficial for complex solos and intricate patterns where precision and agility are crucial.

Benefits of Tight Pick

Tight pick guitar playing enhances precision and control, allowing musicians to execute fast, intricate passages with greater accuracy. The reduced string escape during tight picking improves note clarity and articulation, essential for genres like jazz and metal. Additionally, tight pick techniques minimize string noise and increase playing efficiency, contributing to cleaner, more professional sound production.

Applications Best Suited for Loose Pick

Loose pick cabling is ideal for applications that require greater flexibility and ease of installation, such as temporary setups, horizontal cable runs in office environments, and data centers with frequent reconfigurations. This type of cabling reduces stress on fibers during bends and movements, making it well-suited for environments where cables need to be easily routed or frequently adjusted. Loose pick offers enhanced protection against microbends and macrobends, ensuring signal integrity in dynamic or less controlled installations.

Industries Favoring Tight Pick Methods

Industries such as e-commerce, pharmaceuticals, and electronics heavily favor tight pick methods due to their need for high accuracy and inventory control. Tight pick strategies reduce picking errors and improve traceability, which is essential in sectors with strict regulatory standards and high-value products. Warehouses managing perishable or time-sensitive goods also benefit from tight picking by minimizing waste and ensuring timely order fulfillment.

Impact on Efficiency: Loose Pick vs. Tight Pick

A loose pick in weaving creates more space between warp threads, resulting in lower fabric density but increased speed and efficiency in shuttle movement. Tight pick ensures higher fabric density by closely spacing the threads, enhancing quality but potentially reducing production speed due to increased mechanical resistance. Your choice between loose and tight pick directly impacts weaving efficiency, balancing fabric quality with machine throughput.

Quality Control Considerations

Loose pick fabric features a looser weave, resulting in increased breathability but reduced durability, which requires careful quality control to ensure consistent texture and avoid defects like snagging. Tight pick fabric boasts a denser weave, enhancing strength and resistance to wear, demanding stringent inspection to detect any weaving flaws or tension inconsistencies. Your choice between loose and tight pick significantly impacts quality control processes, influencing factors like fabric resilience and overall product lifespan.

Cost Implications of Each Picking Method

Loose pick methods typically result in higher labor costs due to increased picking time and potential errors, impacting overall warehouse efficiency. Tight pick systems, while often requiring upfront investment in automation or precise inventory management, reduce picking errors and labor expenses over time, improving cost-effectiveness. Your choice between loose and tight picking should weigh initial setup costs against long-term savings in operational expenses.

How to Choose Between Loose Pick and Tight Pick

Choosing between loose pick and tight pick depends on the specific knitting or weaving project requirements, including the desired texture, durability, and flexibility of the fabric. Loose pick creates a softer, more flexible textile with greater drape, ideal for garments needing comfort and stretch, while tight pick results in denser, more durable fabric suited for upholstery or heavy-duty use. Assessing the yarn type, machine capability, and end-use performance helps determine the optimal pick tension for achieving the best balance of strength and elasticity.

Loose Pick vs Tight Pick Infographic

libmatt.com

libmatt.com