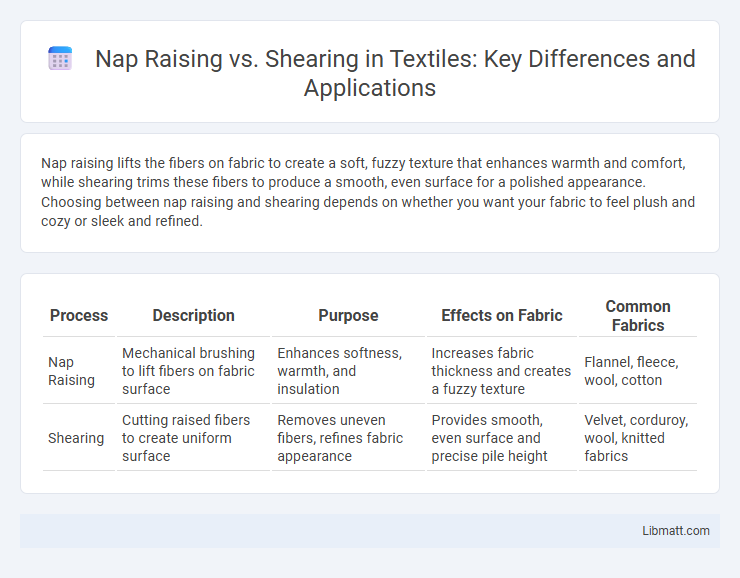

Nap raising lifts the fibers on fabric to create a soft, fuzzy texture that enhances warmth and comfort, while shearing trims these fibers to produce a smooth, even surface for a polished appearance. Choosing between nap raising and shearing depends on whether you want your fabric to feel plush and cozy or sleek and refined.

Table of Comparison

| Process | Description | Purpose | Effects on Fabric | Common Fabrics |

|---|---|---|---|---|

| Nap Raising | Mechanical brushing to lift fibers on fabric surface | Enhances softness, warmth, and insulation | Increases fabric thickness and creates a fuzzy texture | Flannel, fleece, wool, cotton |

| Shearing | Cutting raised fibers to create uniform surface | Removes uneven fibers, refines fabric appearance | Provides smooth, even surface and precise pile height | Velvet, corduroy, wool, knitted fabrics |

Introduction to Nap Raising and Shearing

Nap raising and shearing are essential fabric finishing techniques used to enhance the texture and appearance of textiles. Nap raising involves brushing the fabric surface to lift fibers, creating a soft, fuzzy texture found in materials like flannel or velvet. Shearing follows by precisely trimming the raised fibers to achieve a uniform pile height, improving fabric smoothness and durability.

Defining Nap Raising: Techniques and Purposes

Nap raising involves lifting the fibers on a fabric surface using tools such as teasels, wire brushes, or specialized machines to create a soft, fuzzy texture, enhancing the tactile feel and insulation properties. This technique is commonly applied to materials like flannel, velvet, and fleece, serving both aesthetic and functional purposes by increasing warmth and visual depth. You can distinguish nap raising from shearing, which precisely trims the fiber surface to achieve uniform height and a smooth finish, often used for maintaining velvet or plush fabrics' appearance.

Understanding Shearing in Textile Processing

Shearing in textile processing involves precisely cutting the fabric surface to create an even, smooth texture by removing protruding fibers, which enhances the fabric's appearance and feel. This method contrasts with nap raising, where fibers are lifted to create a soft, fuzzy surface, often used for materials like flannel or velvet. Understanding shearing helps you achieve a clean finish in textiles, ensuring consistent quality and improved aesthetics in your fabric products.

Historical Context: Evolution of Nap Raising and Shearing

Nap raising and shearing evolved during the textile industry's development, with nap raising originating in the medieval period to create softer, insulating fabric surfaces through brushing techniques. Shearing became prominent in the 18th century as a precision method to produce even fabric surfaces by trimming raised fibers to a uniform height. Your understanding of these processes highlights their historical significance in fabric finishing and modern textile refinement.

Key Differences Between Nap Raising and Shearing

Nap raising involves lifting the surface fibers of fabric using a brushing or teasing technique to create a soft, fuzzy texture often found in materials like flannel or velvet. Shearing, on the other hand, is a precision cutting process that trims the raised fibers to an even height, producing a smooth, uniform surface commonly used in wool or pile fabrics. The key differences lie in nap raising enhancing fabric thickness and warmth by elevating fibers, while shearing controls fabric appearance and texture by cutting fibers to achieve a consistent finish.

Materials Best Suited for Nap Raising vs Shearing

Nap raising is best suited for natural fibers like wool, cotton, and flannel, as these materials respond well to brushing techniques that enhance softness and warmth. Shearing works effectively on dense, woven fabrics such as wool suits, blankets, and certain synthetics, where uniform pile length and smooth surfaces are desired. Both processes improve texture but are selected based on fiber type and fabric density for optimal results.

Impact on Fabric Texture and Appearance

Nap raising enhances fabric texture by lifting fibers to create a soft, fuzzy surface that increases warmth and visual depth, often seen in materials like flannel and velvet. Shearing removes the raised fibers, resulting in a smoother, more uniform appearance that prevents pilling and provides a sleek finish preferred in suiting and upholstery. The choice between nap raising and shearing significantly affects the tactile feel and aesthetic, influencing fabric suitability for specific applications.

Role in Enhancing Fabric Performance

Nap raising improves fabric performance by creating a soft, textured surface that enhances warmth and insulation, making it ideal for winter garments and upholstery. Shearing refines fabric quality by trimming surface fibers evenly, resulting in a smooth, uniform appearance that boosts durability and maintains fabric shape. You can choose nap raising for comfort and warmth or shearing for a sleek finish and improved fabric longevity.

Environmental and Economic Considerations

Nap raising, which involves lifting fabric fibers to create a textured surface, typically consumes less energy and produces minimal waste compared to shearing, which mechanically trims fibers and generates significant textile offcuts. Environmentally, nap raising offers a lower carbon footprint due to reduced machine operation time and less material discard, making it a greener choice for fabric finishing. Economically, nap raising can reduce production costs by minimizing energy consumption and waste management expenses, whereas shearing often incurs higher costs related to raw material loss and increased operational complexity.

Choosing the Right Method: Industry Best Practices

Choosing between nap raising and shearing depends on fabric type and desired texture, with nap raising excelling in enhancing softness on boucle, velvet, or fleece materials, while shearing smooths and evens out surface fibers for a polished finish on wool or synthetic blends. Industry best practices recommend nap raising for applications requiring loft and insulation, particularly in upholstery and outerwear, whereas shearing is favored in tailoring and high-end garment production to achieve precise surface uniformity. Evaluating fabric composition, end-use, and aesthetic goals guides manufacturers in selecting the optimal finishing technique to balance tactile appeal and performance.

Nap raising vs Shearing Infographic

libmatt.com

libmatt.com