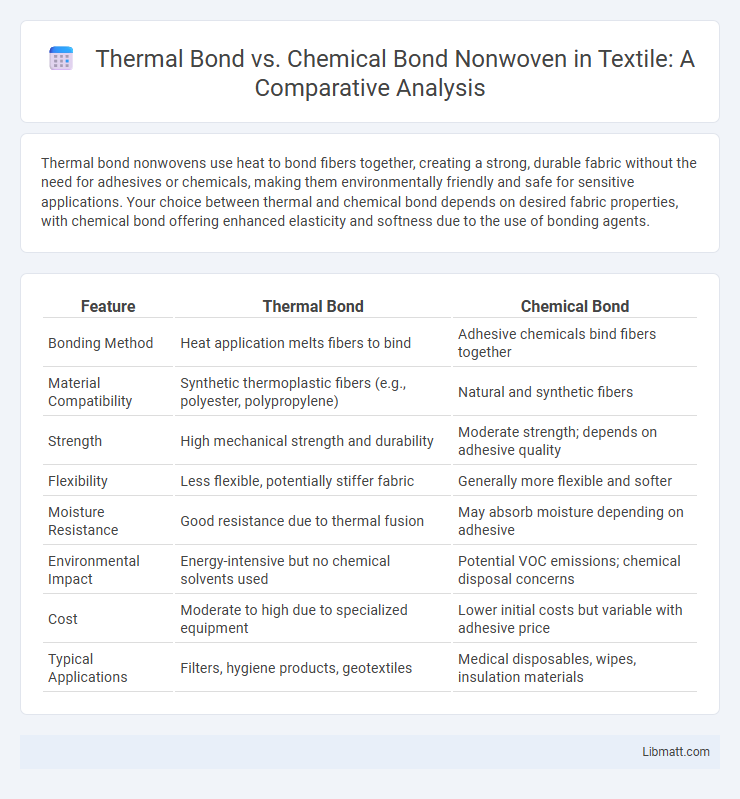

Thermal bond nonwovens use heat to bond fibers together, creating a strong, durable fabric without the need for adhesives or chemicals, making them environmentally friendly and safe for sensitive applications. Your choice between thermal and chemical bond depends on desired fabric properties, with chemical bond offering enhanced elasticity and softness due to the use of bonding agents.

Table of Comparison

| Feature | Thermal Bond | Chemical Bond |

|---|---|---|

| Bonding Method | Heat application melts fibers to bind | Adhesive chemicals bind fibers together |

| Material Compatibility | Synthetic thermoplastic fibers (e.g., polyester, polypropylene) | Natural and synthetic fibers |

| Strength | High mechanical strength and durability | Moderate strength; depends on adhesive quality |

| Flexibility | Less flexible, potentially stiffer fabric | Generally more flexible and softer |

| Moisture Resistance | Good resistance due to thermal fusion | May absorb moisture depending on adhesive |

| Environmental Impact | Energy-intensive but no chemical solvents used | Potential VOC emissions; chemical disposal concerns |

| Cost | Moderate to high due to specialized equipment | Lower initial costs but variable with adhesive price |

| Typical Applications | Filters, hygiene products, geotextiles | Medical disposables, wipes, insulation materials |

Introduction to Nonwoven Bonding Methods

Thermal bond nonwovens utilize heat and pressure to fuse synthetic fibers together, creating strong and durable fabrics without the use of adhesives or chemicals. Chemical bond nonwovens employ binders or adhesives to adhere fibers, offering flexibility in texture and enhanced tensile strength. Each bonding method impacts the physical properties and applications of nonwoven materials in industries such as filtration, hygiene, and automotive.

What is Thermal Bonding in Nonwovens?

Thermal bonding in nonwovens involves using heat to fuse fibers together without adhesives, creating strong, durable fabrics primarily from thermoplastic fibers like polypropylene or polyester. This process enhances fabric strength, softness, and water resistance by melting fiber surfaces and bonding them upon cooling. Compared to chemical bonding, thermal bonded nonwovens avoid chemical residues, offering eco-friendly and cost-effective production with consistent quality.

What is Chemical Bonding in Nonwovens?

Chemical bonding in nonwovens involves using adhesives or binders to fuse fibers together, creating a strong and durable fabric structure without the need for heat or pressure. This method provides enhanced flexibility and softness compared to thermal bonds, making it ideal for applications requiring comfort and durability. Your choice of chemical bonding can significantly impact the nonwoven's properties such as absorbency, strength, and resistance to washing or chemicals.

Key Differences: Thermal Bond vs Chemical Bond

Thermal bond nonwoven fabrics use heat to melt fibers together, creating strong, durable bonds without the need for adhesives, while chemical bond nonwoven fabrics rely on bonding agents or adhesives to join fibers. Thermal bonding enhances fabric rigidity and improves breathability due to the absence of chemicals, whereas chemical bonding offers more flexibility in fabric softness and texture. Your choice between these bonding methods depends on the desired strength, texture, and application of the nonwoven material.

Strength and Durability Comparison

Thermal bond nonwovens exhibit moderate strength with fibers fused through heat, offering consistent durability and resistance to moisture and chemicals. Chemical bond nonwovens provide higher tensile strength and enhanced durability due to adhesive resins that create stronger fiber cohesion, but they may exhibit reduced flexibility and increased sensitivity to chemicals. Strength and durability in thermal bonds rely on fiber melting points and bonding patterns, while chemical bonds depend on resin type and curing processes, influencing long-term performance in various applications.

Applications of Thermal Bond Nonwovens

Thermal bond nonwovens are extensively used in hygiene products such as diapers and sanitary napkins due to their softness, strength, and breathability. They find applications in automotive interiors and filtration systems where durability and resistance to chemicals are essential. These nonwovens are preferred in medical textiles for wound care and surgical gowns because of their sterilization compatibility and barrier properties.

Applications of Chemical Bond Nonwovens

Chemical bond nonwovens are widely used in medical textiles, including surgical gowns, masks, and wound dressings, due to their excellent barrier properties and biocompatibility. These nonwovens also find applications in filtration systems, such as air and liquid filters, where chemical bonding provides durable strength and resistance to harsh environments. Additionally, chemical bond nonwovens are utilized in automotive interiors and geotextiles, offering enhanced durability and stability under mechanical stress.

Environmental Impact: Thermal vs Chemical Bonding

Thermal bonded nonwovens typically have a lower environmental impact compared to chemical bonded alternatives because they use heat to fuse fibers without additional adhesives or solvents, reducing chemical emissions and potential toxicity. Chemical bonding often involves synthetic resins and binders that may release volatile organic compounds (VOCs) and require energy-intensive manufacturing processes, contributing to pollution and resource depletion. Choosing thermal bonded nonwoven fabrics can enhance sustainability in your projects by minimizing harmful environmental effects while maintaining material strength and durability.

Cost Considerations in Bonding Methods

Thermal bond nonwovens typically incur lower production costs due to energy-efficient processes and reduced use of adhesives, making them more economical for large-scale manufacturing. Chemical bonds involve pricey adhesives and longer processing times, increasing material and labor expenses. Cost considerations favor thermal bonding in applications demanding budget-friendly, durable nonwoven fabrics.

Choosing the Right Bonding Technique for Your Needs

Thermal bond nonwovens utilize heat to melt fibers together, creating a strong, durable fabric ideal for medical masks and filtration applications where softness and breathability are essential. Chemical bond nonwovens rely on adhesives to bind fibers, offering flexibility in texture and strength, making them suitable for automotive interiors and hygiene products requiring enhanced elasticity. Selecting the right bonding technique depends on factors such as desired product strength, softness, application requirements, and environmental considerations like biodegradability and chemical resistance.

Thermal bond vs Chemical bond nonwoven Infographic

libmatt.com

libmatt.com