Spun yarn consists of short fibers twisted together, providing a soft texture and greater warmth, ideal for cozy garments and knitwear. Filament yarn, made from continuous long fibers, offers smoothness, strength, and sheen, making it perfect for fine fabrics and high-performance textiles.

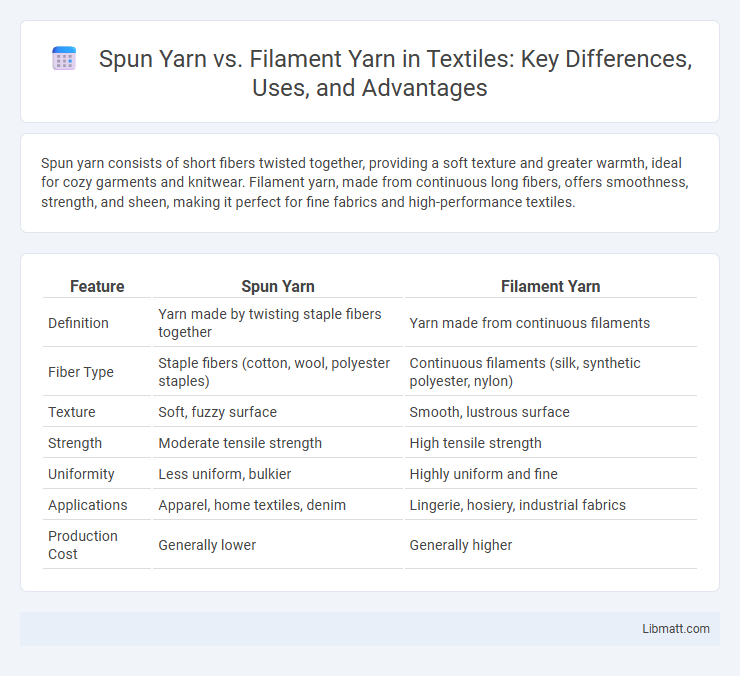

Table of Comparison

| Feature | Spun Yarn | Filament Yarn |

|---|---|---|

| Definition | Yarn made by twisting staple fibers together | Yarn made from continuous filaments |

| Fiber Type | Staple fibers (cotton, wool, polyester staples) | Continuous filaments (silk, synthetic polyester, nylon) |

| Texture | Soft, fuzzy surface | Smooth, lustrous surface |

| Strength | Moderate tensile strength | High tensile strength |

| Uniformity | Less uniform, bulkier | Highly uniform and fine |

| Applications | Apparel, home textiles, denim | Lingerie, hosiery, industrial fabrics |

| Production Cost | Generally lower | Generally higher |

Introduction to Yarn Types

Spun yarn consists of short staple fibers twisted together, offering a soft, textured feel ideal for casual wear and comfort-focused textiles. Filament yarn is made from continuous strands of fiber, creating a smooth, lustrous surface commonly used in high-performance and luxury fabrics. Understanding the distinct structures and properties of spun and filament yarns is crucial for textile manufacturing and fabric selection.

What is Spun Yarn?

Spun yarn consists of short staple fibers twisted together to form a continuous thread, commonly made from cotton, wool, or synthetic fibers. It offers a soft, warm texture ideal for comfort and insulation in garments and home textiles. If you seek breathable, versatile fabric with a natural feel, spun yarn is a suitable choice for your textile needs.

What is Filament Yarn?

Filament yarn consists of long, continuous fibers that are smooth and uniform, typically made from synthetic materials like nylon, polyester, or silk. This type of yarn offers high tensile strength, sheen, and durability, making it ideal for applications requiring smooth textures and minimal pilling. Understanding filament yarn helps you choose fabrics that provide a sleek finish and enhanced performance in textiles or apparel.

Manufacturing Process Comparison

Spun yarn is produced by twisting together short staple fibers such as cotton or wool, using processes like carding, combing, and ring spinning to create a cohesive thread with a slightly uneven texture. Filament yarn, made from continuous synthetic or natural fibers like polyester or silk, involves extrusion through spinnerets or reeling from cocoons, resulting in a smoother and stronger yarn with consistent thickness. Your choice depends on the desired fabric characteristics, with spun yarn offering breathability and softness and filament yarn providing durability and sheen.

Key Physical Properties

Spun yarn consists of short staple fibers twisted together, resulting in a soft, breathable texture with slightly higher porosity and irregular surface, ideal for comfort and warmth. Filament yarn is made from continuous fibers, yielding a smooth, strong, and lustrous thread with low stretch and excellent durability. Your choice impacts fabric strength, appearance, and comfort, depending on whether softness or tensile strength is prioritized.

Performance and Durability

Spun yarn, made from short staple fibers twisted together, offers excellent breathability and softness, making it ideal for comfort-focused textiles but with moderate durability due to fiber ends that can cause pilling. Filament yarn, composed of continuous synthetic or natural fibers like polyester or silk, provides superior strength, smoothness, and resistance to abrasion, resulting in enhanced durability and longevity in performance fabrics. The construction differences lead filament yarns to outperform spun yarns in high-stress applications requiring abrasion resistance and tensile strength.

Common Applications

Spun yarn, made from short staple fibers twisted together, is commonly used in apparel fabrics, home textiles, and casual wear, offering softness and breathability. Filament yarns, composed of continuous fibers, are preferred in high-performance activewear, lingerie, and industrial textiles for their strength, smooth texture, and sheen. Your choice between spun and filament yarns should align with the specific durability and aesthetic requirements of your textile project.

Cost Differences

Spun yarn typically incurs lower production costs due to the use of short staple fibers and simpler manufacturing processes, making it more affordable for everyday textiles. Filament yarn, made from continuous synthetic or silk fibers, involves higher expenses linked to raw materials and advanced machinery, resulting in a cost premium. Understanding these cost differences helps you select the most economical yarn type suited for your textile applications.

Environmental Impact

Spun yarn, produced from short staple fibers, often relies on natural or recycled materials with lower energy consumption during manufacturing, resulting in a smaller carbon footprint compared to filament yarn made from synthetic polymers. Filament yarn, typically derived from petrochemical-based fibers like polyester or nylon, entails high fossil fuel usage and generates significant microplastic pollution during washing and wear. Sustainable alternatives in spun yarn, such as organic cotton or recycled wool, offer enhanced biodegradability and reduced environmental impact relative to the predominantly non-biodegradable nature of synthetic filament yarns.

Choosing the Right Yarn

Choosing the right yarn depends on the application and desired fabric characteristics; spun yarn, composed of short staple fibers twisted together, offers softness and breathability ideal for casual wear and knit fabrics, while filament yarn consists of continuous strands providing smoothness, strength, and sheen suited for lingerie and formal garments. Spun yarn's fuzzy texture enhances moisture absorption and warmth, fitting for comfort-focused textiles, whereas filament yarn's uniform surface reduces friction and enhances durability, preferred in performance and high-sheen fabrics. An informed selection between spun and filament yarn optimizes fabric performance, appearance, and end-use suitability in textile manufacturing.

Spun yarn vs Filament yarn Infographic

libmatt.com

libmatt.com