Nonwoven fabrics are made by bonding fibers together through chemical, mechanical, or thermal processes, offering advantages such as lightweight, high absorbency, and disposability, making them ideal for medical and hygiene products. Woven fabrics consist of interlaced threads in a structured pattern, providing durability, strength, and flexibility, which are essential for clothing, upholstery, and industrial applications.

Table of Comparison

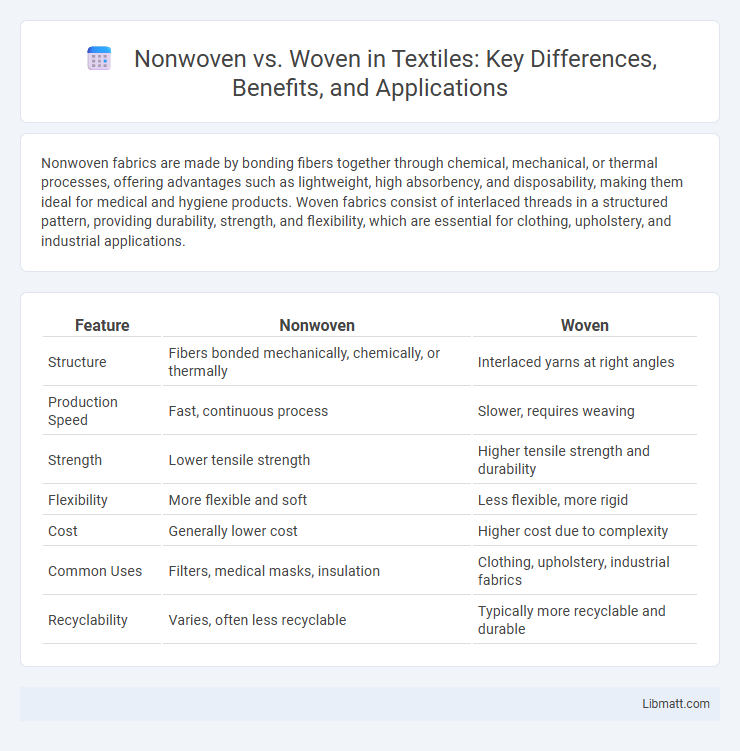

| Feature | Nonwoven | Woven |

|---|---|---|

| Structure | Fibers bonded mechanically, chemically, or thermally | Interlaced yarns at right angles |

| Production Speed | Fast, continuous process | Slower, requires weaving |

| Strength | Lower tensile strength | Higher tensile strength and durability |

| Flexibility | More flexible and soft | Less flexible, more rigid |

| Cost | Generally lower cost | Higher cost due to complexity |

| Common Uses | Filters, medical masks, insulation | Clothing, upholstery, industrial fabrics |

| Recyclability | Varies, often less recyclable | Typically more recyclable and durable |

Introduction to Nonwoven and Woven Fabrics

Nonwoven fabrics are engineered materials made by bonding fibers together through mechanical, chemical, or thermal processes without weaving or knitting, offering lightweight and disposable solutions. Woven fabrics consist of interlaced yarns arranged perpendicularly, resulting in strong and durable textiles commonly used in clothing and upholstery. The distinct manufacturing techniques of nonwoven and woven fabrics determine their structural properties, applications, and cost-effectiveness in industries such as healthcare, automotive, and fashion.

Defining Nonwoven Fabrics

Nonwoven fabrics are engineered from fibers bonded together through chemical, mechanical, heat, or solvent treatment, rather than being woven or knitted. These materials offer unique properties such as enhanced filtration, breathability, and cost-effective production, making them ideal for medical gowns, disposable wipes, and geotextiles. Understanding the difference between nonwoven and woven fabrics helps you select the right textile for durability, flexibility, and specific performance needs.

Understanding Woven Fabrics

Woven fabrics are created by interlacing two sets of yarns at right angles, producing a strong and durable textile with notable dimensional stability and breathability. This structure allows woven fabrics to maintain their shape well and offers superior strength compared to nonwoven materials, making them ideal for applications requiring longevity and resilience. Understanding woven fabrics helps you choose the right material for products like clothing, upholstery, and industrial textiles where durability and performance are critical.

Manufacturing Processes: Nonwoven vs Woven

Nonwoven fabrics are manufactured through processes like spunbonding, meltblowing, and needle punching, which involve bonding fibers together using heat, chemicals, or mechanical entanglement without weaving or knitting. Woven fabrics result from interlacing yarns at right angles on looms, creating structured patterns such as plain, twill, or satin weaves through warp and weft arrangements. The nonwoven process enables rapid production with versatile fiber orientations, while woven manufacturing emphasizes durability and uniformity through precise yarn interlacement.

Key Material Differences

Nonwoven fabrics are made from fibers bonded together through chemical, mechanical, heat, or solvent treatment, creating a dense, uniform sheet without weaving or knitting processes. Woven fabrics consist of interlaced yarns arranged in perpendicular patterns, providing strength and durability through their structured weave. Understanding these key material differences helps you select the right fabric for applications requiring specific properties like breathability, texture, or tensile strength.

Performance Characteristics Comparison

Nonwoven fabrics offer superior filtration, absorbency, and lightweight properties compared to woven fabrics, which excel in durability, strength, and breathability due to their interlaced yarn structure. Nonwovens typically provide better cost efficiency and faster production rates, while woven textiles maintain greater resistance to abrasion and can be reused multiple times. Your choice depends on the required performance characteristics like tensile strength, moisture management, and application-specific durability.

Cost and Production Efficiency

Nonwoven fabrics typically offer lower production costs and faster manufacturing speeds compared to woven textiles due to their simplified processes like spunbond or meltblown methods. Woven fabrics require more time and labor-intensive steps such as weaving yarns on looms, resulting in higher material and operational expenses. The cost-effectiveness of nonwoven production makes it ideal for disposable and high-volume applications, while woven fabrics are preferred for durability and long-term use despite increased production investments.

Common Applications of Nonwoven Fabrics

Nonwoven fabrics are widely used in medical supplies such as surgical gowns, masks, and wound dressings due to their disposable, hygienic properties. They are also essential in filtration systems, geotextiles for soil stabilization, and automotive interiors where lightweight and durability are required. The versatility and cost-effectiveness of nonwoven materials make them popular in hygiene products like diapers, wet wipes, and feminine care items.

Typical Uses of Woven Fabrics

Woven fabrics are commonly used in apparel, upholstery, and home textiles due to their durability and structural integrity. They are ideal for garments like shirts, pants, and jackets, as well as furniture covers and curtains. The tight interlacing of threads in woven fabrics provides strength and resistance to wear, making them suitable for both fashion and industrial applications.

Choosing the Right Fabric: Factors to Consider

When choosing the right fabric between nonwoven and woven, consider durability, breathability, and intended use to ensure optimal performance. Nonwoven fabrics offer lightweight, disposable options ideal for medical and hygiene products, while woven fabrics provide strength and flexibility suited for apparel and upholstery. Evaluating your project's requirements for texture, longevity, and cost will guide you to the best fabric choice for your needs.

Nonwoven vs Woven Infographic

libmatt.com

libmatt.com