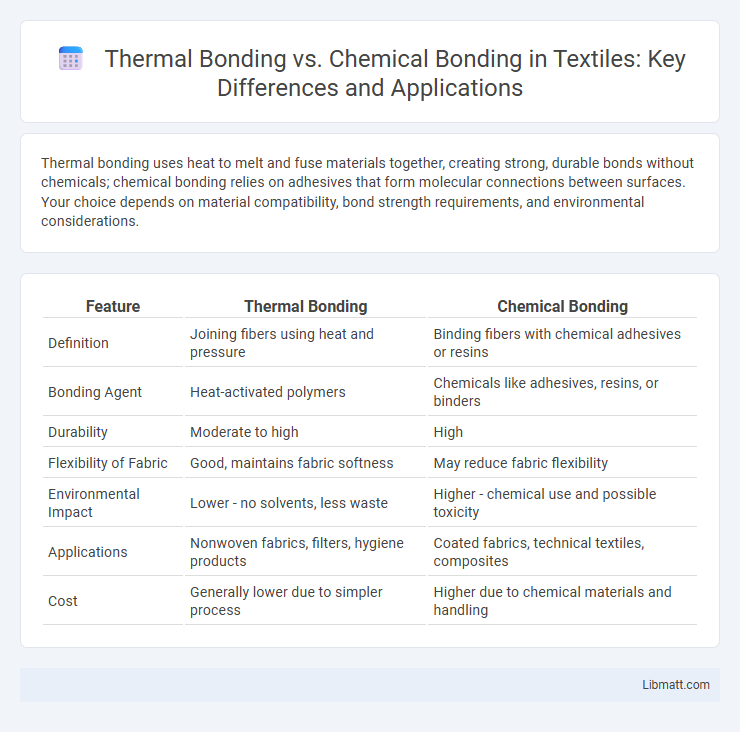

Thermal bonding uses heat to melt and fuse materials together, creating strong, durable bonds without chemicals; chemical bonding relies on adhesives that form molecular connections between surfaces. Your choice depends on material compatibility, bond strength requirements, and environmental considerations.

Table of Comparison

| Feature | Thermal Bonding | Chemical Bonding |

|---|---|---|

| Definition | Joining fibers using heat and pressure | Binding fibers with chemical adhesives or resins |

| Bonding Agent | Heat-activated polymers | Chemicals like adhesives, resins, or binders |

| Durability | Moderate to high | High |

| Flexibility of Fabric | Good, maintains fabric softness | May reduce fabric flexibility |

| Environmental Impact | Lower - no solvents, less waste | Higher - chemical use and possible toxicity |

| Applications | Nonwoven fabrics, filters, hygiene products | Coated fabrics, technical textiles, composites |

| Cost | Generally lower due to simpler process | Higher due to chemical materials and handling |

Introduction to Bonding Techniques

Thermal bonding uses heat to fuse materials, creating strong, durable connections without the need for adhesives or solvents, commonly applied in plastics and textiles. Chemical bonding involves using adhesives or reactive agents to form molecular links between surfaces, offering versatility and precision in various industrial applications. Understanding the differences between thermal bonding and chemical bonding helps you select the most efficient technique based on material properties and desired bond strength.

What is Thermal Bonding?

Thermal bonding is a fabrication process that uses heat to join materials, typically thermoplastics, by melting their surfaces to create a strong, seamless bond upon cooling. Unlike chemical bonding, which relies on adhesives or chemical reactions to link materials, thermal bonding produces a durable and clean connection without introducing additional substances. Your choice between thermal bonding and chemical bonding depends on factors such as material compatibility, bond strength requirements, and application environment.

What is Chemical Bonding?

Chemical bonding refers to the process where atoms or molecules combine through the sharing, donating, or receiving of electrons, resulting in the formation of stable compounds. It encompasses various types such as covalent, ionic, and metallic bonds, each involving distinct interactions at the atomic level. This fundamental mechanism governs the structure and properties of molecules, differentiating it from thermal bonding which relies on heat to fuse materials physically rather than chemically.

Key Differences Between Thermal and Chemical Bonding

Thermal bonding uses heat to fuse materials, primarily thermoplastics, by melting their surfaces to form a strong joint without additional substances. Chemical bonding relies on adhesives or chemical reactions to create molecular connections between surfaces, offering versatility across diverse materials. Understanding your project requirements helps determine whether the heat-based process of thermal bonding or the molecular approach of chemical bonding is more suitable for durability and application needs.

Advantages of Thermal Bonding

Thermal bonding offers significant advantages such as improved fabric strength and durability due to the melting and fusion of fibers without the need for adhesives or chemicals. It ensures an eco-friendly process by eliminating the use of solvents or toxic substances, making it safer for both workers and the environment. The method also facilitates faster production cycles and cost efficiency by reducing drying times and minimizing the number of processing steps required.

Advantages of Chemical Bonding

Chemical bonding offers superior adhesion strength and chemical resistance compared to thermal bonding, making it ideal for applications requiring durable and long-lasting bonds. This method provides consistent bonding quality without the risk of thermal distortion or weakening of materials. Your products benefit from enhanced stability and performance, especially in environments exposed to moisture, heat, or chemicals.

Applications of Thermal Bonding

Thermal bonding is widely used in industries such as textiles, packaging, and automotive manufacturing for creating strong, durable joins without adhesives or solvents. Its applications include fabric lamination, nonwoven material production, and assembling plastic parts where heat activation fuses materials together. Your products benefit from thermal bonding's eco-friendly process and enhanced structural integrity.

Applications of Chemical Bonding

Chemical bonding is extensively applied in manufacturing adhesives, coatings, and composite materials, where strong intermolecular forces ensure durability and resistance. It plays a critical role in pharmaceuticals for drug formulation, enabling precise molecular interactions and stability. Industrial processes utilize chemical bonding for polymer synthesis, enhancing material properties and performance in textiles, packaging, and automotive components.

Factors to Consider When Choosing a Bonding Method

When choosing between thermal bonding and chemical bonding, consider factors such as material compatibility, bond strength requirements, and environmental conditions. Thermal bonding is ideal for thermoplastics and offers strong, durable joints without the need for adhesives, whereas chemical bonding works well with a wider range of materials but requires careful handling of solvents or adhesives. Your choice should balance the desired mechanical properties, processing time, and potential health and safety concerns.

Conclusion: Which Bonding Method is Best?

Thermal bonding offers strong, durable connections ideal for materials that can withstand heat, while chemical bonding provides precise adhesion for sensitive or complex substrates. Your choice depends on the material type, application requirements, and environmental conditions. Assess these factors to determine the most effective bonding method for your project.

Thermal bonding vs Chemical bonding Infographic

libmatt.com

libmatt.com