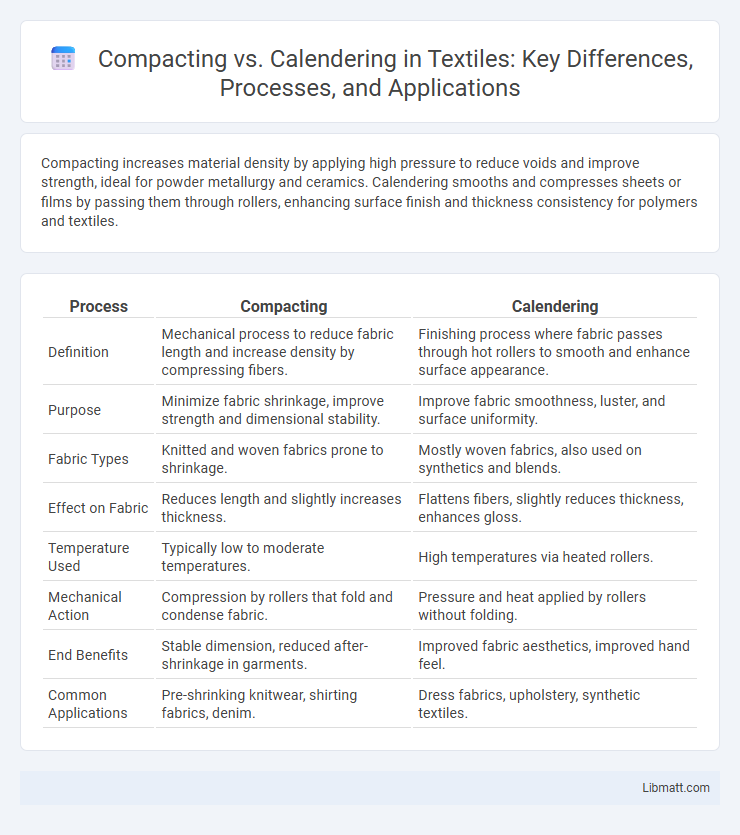

Compacting increases material density by applying high pressure to reduce voids and improve strength, ideal for powder metallurgy and ceramics. Calendering smooths and compresses sheets or films by passing them through rollers, enhancing surface finish and thickness consistency for polymers and textiles.

Table of Comparison

| Process | Compacting | Calendering |

|---|---|---|

| Definition | Mechanical process to reduce fabric length and increase density by compressing fibers. | Finishing process where fabric passes through hot rollers to smooth and enhance surface appearance. |

| Purpose | Minimize fabric shrinkage, improve strength and dimensional stability. | Improve fabric smoothness, luster, and surface uniformity. |

| Fabric Types | Knitted and woven fabrics prone to shrinkage. | Mostly woven fabrics, also used on synthetics and blends. |

| Effect on Fabric | Reduces length and slightly increases thickness. | Flattens fibers, slightly reduces thickness, enhances gloss. |

| Temperature Used | Typically low to moderate temperatures. | High temperatures via heated rollers. |

| Mechanical Action | Compression by rollers that fold and condense fabric. | Pressure and heat applied by rollers without folding. |

| End Benefits | Stable dimension, reduced after-shrinkage in garments. | Improved fabric aesthetics, improved hand feel. |

| Common Applications | Pre-shrinking knitwear, shirting fabrics, denim. | Dress fabrics, upholstery, synthetic textiles. |

Introduction to Compacting and Calendering

Compacting and calendering are essential processes in material manufacturing used to enhance the physical properties of powders and sheets, respectively. Compacting involves compressing powder particles into a dense, cohesive mass to improve strength and reduce porosity, commonly utilized in metallurgy and ceramics. Calendering passes materials like plastic or rubber through rollers to achieve uniform thickness and surface finish, crucial for products such as films and coated fabrics.

Defining Compacting: Process and Applications

Compacting is a manufacturing process that involves compressing powder particles into a dense, cohesive mass, enhancing material strength and reducing porosity. Commonly used in powder metallurgy, pharmaceuticals, and ceramics, compacting shapes raw materials into precise forms before sintering or further processing. Your production efficiency and product quality improve significantly when applying compacting for uniform density and structural integrity.

Understanding Calendering: Mechanics and Uses

Calendering involves passing materials such as paper, textiles, or plastics through a series of heated rollers to smooth, compress, and enhance surface finish, improving gloss and thickness uniformity. This mechanical process increases material density and strengthens flexural properties, making it essential in manufacturing high-quality films, sheets, and coated papers. Your understanding of calendering mechanics enables better control over product characteristics, ensuring optimal performance in applications requiring precise surface texture and dimensional stability.

Key Differences Between Compacting and Calendering

Compacting involves compressing powder particles into a dense, solid form using high pressure, primarily used in tablet manufacturing and powder metallurgy. Calendering is a process where a material, such as plastic or rubber, is passed through rollers to produce thin sheets with uniform thickness and smooth surfaces. Your choice between compacting and calendering depends on whether you need solid compression for particle bonding or surface finishing with precise thickness control.

Materials Suitable for Compacting vs Calendering

Compacting is ideal for powdered materials, such as metal powders and ceramics, where particles are compressed into dense, uniform shapes. Calendering suits flexible materials like plastics, rubber, and textiles by passing them through rollers to achieve smooth, thin sheets. Your choice depends on the material's physical state and desired product characteristics.

Equipment Used in Compacting and Calendering Processes

Compacting equipment typically includes roll compactors and briquetting machines designed to compress powder or granules into dense, uniform sheets or briquettes, optimizing material flow and density. Calendering employs calender rolls or rollers that apply controlled pressure and heat to materials like rubber, plastics, or textiles, producing thin, smooth, and consistent sheets or films. Both processes require precision-engineered machinery tailored to material properties and desired product specifications for maximum efficiency and quality control.

Advantages of Compacting in Manufacturing

Compacting in manufacturing enhances powder density and improves uniformity, leading to stronger and more durable finished products. This process reduces porosity and minimizes material waste, resulting in cost-effective production and higher mechanical performance. Compacting also allows for better control over product dimensions, ensuring consistent quality across large production runs.

Benefits of Calendering for Material Processing

Calendering enhances material density and surface smoothness, improving mechanical properties and aesthetic appeal. It boosts production efficiency by enabling continuous processing with precise thickness control, ideal for polymers, textiles, and paper industries. The process reduces material porosity, increasing durability and facilitating superior coating and printing applications.

Common Industries Utilizing Compacting and Calendering

Compacting and calendering are essential processes in industries such as textiles, paper manufacturing, and plastics where material density and surface finish are critical. Compacting is widely used in pharmaceutical and ceramic industries to enhance powder cohesion and structural integrity, while calendering is prevalent in rubber and plastic production for achieving smooth, uniform sheets. Your choice between these methods depends on the desired material characteristics and industry-specific requirements.

Choosing the Right Process: Compacting or Calendering?

Choosing between compacting and calendering depends on the desired material properties and application requirements. Compacting enhances density and reduces porosity by applying high pressure to powders, ideal for producing strong, uniform metal or ceramic parts. Calendering involves passing materials through rollers to achieve precise thickness and surface finish, making it suitable for flexible sheets like plastics, rubber, or textiles that require smooth, consistent profiles.

Compacting vs Calendering Infographic

libmatt.com

libmatt.com