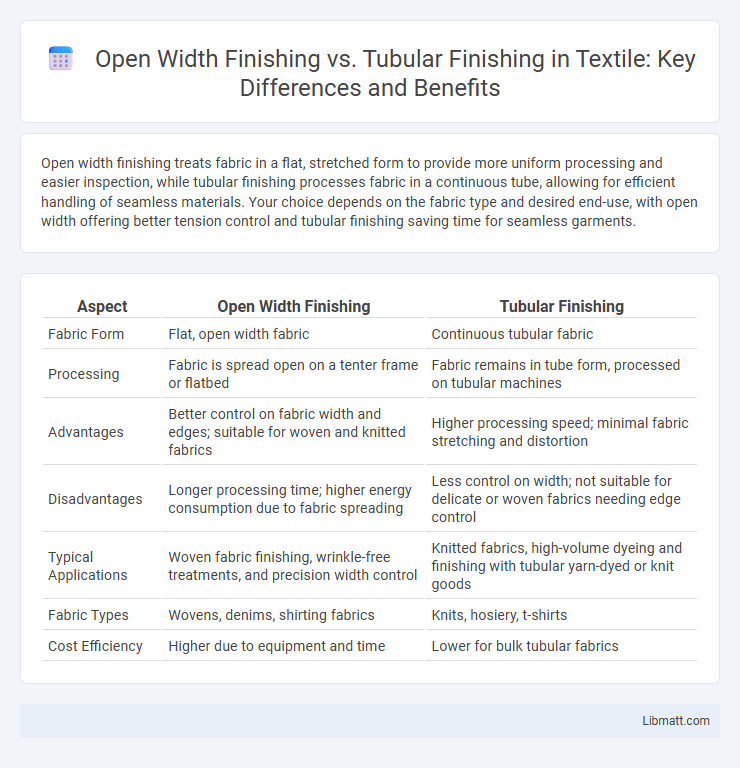

Open width finishing treats fabric in a flat, stretched form to provide more uniform processing and easier inspection, while tubular finishing processes fabric in a continuous tube, allowing for efficient handling of seamless materials. Your choice depends on the fabric type and desired end-use, with open width offering better tension control and tubular finishing saving time for seamless garments.

Table of Comparison

| Aspect | Open Width Finishing | Tubular Finishing |

|---|---|---|

| Fabric Form | Flat, open width fabric | Continuous tubular fabric |

| Processing | Fabric is spread open on a tenter frame or flatbed | Fabric remains in tube form, processed on tubular machines |

| Advantages | Better control on fabric width and edges; suitable for woven and knitted fabrics | Higher processing speed; minimal fabric stretching and distortion |

| Disadvantages | Longer processing time; higher energy consumption due to fabric spreading | Less control on width; not suitable for delicate or woven fabrics needing edge control |

| Typical Applications | Woven fabric finishing, wrinkle-free treatments, and precision width control | Knitted fabrics, high-volume dyeing and finishing with tubular yarn-dyed or knit goods |

| Fabric Types | Wovens, denims, shirting fabrics | Knits, hosiery, t-shirts |

| Cost Efficiency | Higher due to equipment and time | Lower for bulk tubular fabrics |

Introduction to Fabric Finishing Methods

Open width finishing processes involve treating fabric laid out flat and stretched on a wide tenter frame, ensuring uniform application of chemical finishes and consistent fabric width. Tubular finishing processes treat fabric in a continuous tube form, allowing efficient handling of knits and seamless garments but may result in uneven finish penetration compared to open width. Your choice between these methods depends on fabric type, desired finish quality, and production efficiency requirements.

Overview of Open Width Finishing

Open width finishing processes treat fabric in a flat, stretched form to ensure uniform dyeing, printing, and chemical application, enhancing color consistency and fabric quality. Unlike tubular finishing, which processes fabric in tubular form, open width finishing allows precise control over fabric tension and width, making it ideal for printed or printed-look textiles. Your choice of finishing method impacts production efficiency and the final fabric appearance, with open width finishing favored for its effectiveness in treating woven and knit fabrics uniformly.

Tubular Finishing Explained

Tubular finishing involves processing fabric that is knit in a circular form, eliminating the need for side seams and resulting in a seamless tube of material ideal for garments requiring stretch and comfort. This method preserves the integrity of the textile's knit structure, enhancing durability and reducing production time compared to open width finishing, where the fabric is laid flat and cut. Tubular finishing is commonly used in manufacturing t-shirts, hosiery, and activewear, where garment flexibility and shape retention are critical.

Key Process Differences

Open width finishing processes involve treating fabric that has been spread out flat and cut open, allowing for uniform application of finishes, better control over tension, and precise dimensional stability. Tubular finishing treats fabric in a continuous tube form, offering higher production efficiency but with challenges in applying finishes evenly and potential distortion in fabric dimensions. The choice between these methods hinges on fabric type, desired finish quality, and production scale, impacting the consistency and performance of the final textile product.

Impact on Fabric Quality and Properties

Open width finishing enhances fabric uniformity and dimensional stability by processing the material in a flat, spread-out state, resulting in consistent surface characteristics and reduced distortion. Tubular finishing maintains the fabric in a tube form, often preserving natural stretch and elasticity, which benefits knit fabrics requiring flexibility and seamlessness. Your choice between these methods directly impacts the final texture, appearance, and mechanical properties of the fabric, influencing its suitability for specific applications.

Production Efficiency and Cost Comparison

Open width finishing provides higher production efficiency by allowing fabric to be processed in a flattened form, reducing handling time and optimizing drying and sheeting operations. Tubular finishing, while simpler in initial fabric formation, often incurs higher costs due to slower processing speeds and increased energy consumption needed to handle the tubular fabric. Cost comparison favors open width finishing for large-scale production with better fabric uniformity, whereas tubular finishing may be more economical for smaller batches or specific fabric types requiring minimal distortion.

Effects on Dyeing and Printing Results

Open width finishing allows fabrics to be spread flat, enabling uniform dye absorption and consistent printing clarity, which enhances color precision and reduces streaking. Tubular finishing involves processing fabric in a tube form, which can cause dye penetration challenges and potential pattern distortion, affecting print sharpness and color vibrancy. Choosing between these methods impacts Your final textile quality, with open width preferred for high-definition prints and tubular better suited for seamless garments.

Sustainability and Resource Utilization

Open width finishing enhances sustainability by reducing water and energy consumption through more efficient fabric processing, minimizing waste during the finishing stages. Tubular finishing, although offering seamless fabric production, tends to require more energy due to continuous circular knitting and finishing processes. Your choice between open width and tubular finishing impacts resource utilization, with open width finishing generally providing a more eco-friendly and resource-efficient option for sustainable textile manufacturing.

Industry Applications and Suitability

Open width finishing is ideal for fabrics used in garments requiring flat, uniform surfaces such as shirting, home textiles, and upholstery, offering precise control over fabric dimensions and surface treatments. Tubular finishing suits industries producing seamless or tubular items like t-shirts, hosiery, and sportswear, providing efficient processing for knit fabrics without edge distortion. Your choice between these methods depends on the fabric type and end-use application, ensuring optimal quality and performance for specific textile products.

Choosing the Right Finishing Method

Choosing the right finishing method depends on the fabric type and desired garment structure. Open width finishing offers uniform treatment for woven fabrics, enhancing colorfastness and reducing shrinkage, while tubular finishing suits knit fabrics by preserving fabric stretch and shape. Your choice directly impacts fabric performance, durability, and final appearance, making it essential to match finishing techniques to your production needs.

Open width finishing vs Tubular finishing Infographic

libmatt.com

libmatt.com