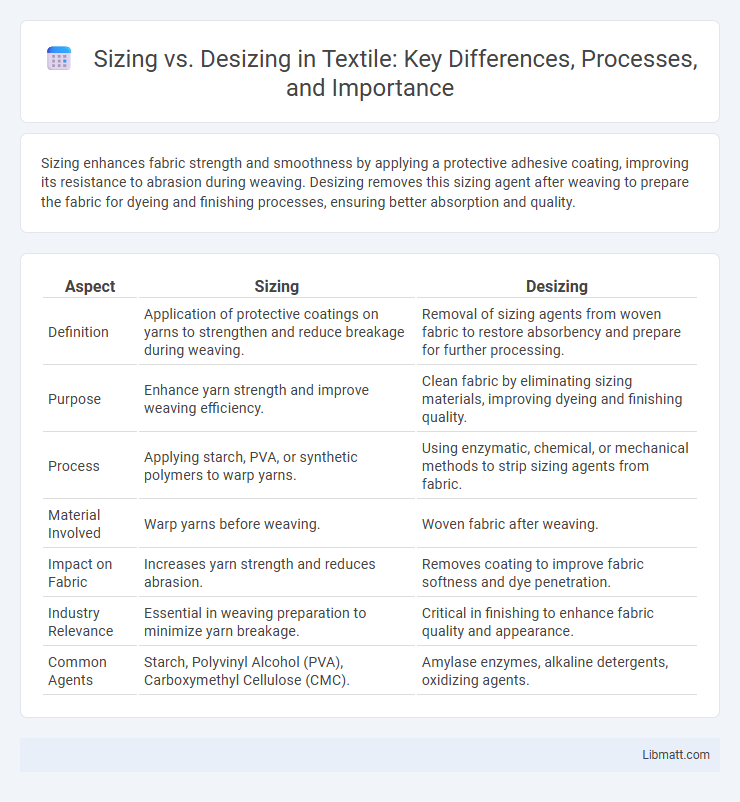

Sizing enhances fabric strength and smoothness by applying a protective adhesive coating, improving its resistance to abrasion during weaving. Desizing removes this sizing agent after weaving to prepare the fabric for dyeing and finishing processes, ensuring better absorption and quality.

Table of Comparison

| Aspect | Sizing | Desizing |

|---|---|---|

| Definition | Application of protective coatings on yarns to strengthen and reduce breakage during weaving. | Removal of sizing agents from woven fabric to restore absorbency and prepare for further processing. |

| Purpose | Enhance yarn strength and improve weaving efficiency. | Clean fabric by eliminating sizing materials, improving dyeing and finishing quality. |

| Process | Applying starch, PVA, or synthetic polymers to warp yarns. | Using enzymatic, chemical, or mechanical methods to strip sizing agents from fabric. |

| Material Involved | Warp yarns before weaving. | Woven fabric after weaving. |

| Impact on Fabric | Increases yarn strength and reduces abrasion. | Removes coating to improve fabric softness and dye penetration. |

| Industry Relevance | Essential in weaving preparation to minimize yarn breakage. | Critical in finishing to enhance fabric quality and appearance. |

| Common Agents | Starch, Polyvinyl Alcohol (PVA), Carboxymethyl Cellulose (CMC). | Amylase enzymes, alkaline detergents, oxidizing agents. |

Introduction to Sizing and Desizing

Sizing enhances fabric strength and smoothness by applying a protective adhesive coating, improving weaving efficiency and fabric quality. Desizing removes this sizing agent after weaving, preparing the fabric for dyeing or finishing processes by restoring its absorbency. Both processes are essential in textile manufacturing to optimize fabric performance and appearance.

Definition of Sizing in Textile Processing

Sizing in textile processing refers to the application of a protective adhesive coating, typically composed of starch, polyvinyl alcohol, or synthetic polymers, onto warp yarns to enhance their strength and reduce breakage during weaving. This process improves the yarns' abrasion resistance and smoothness, facilitating efficient fabric production. Unlike desizing, which removes these size materials post-weaving, sizing is a preparatory step aimed at optimizing yarn performance.

Importance and Objectives of Sizing

Sizing enhances fabric strength and surface smoothness by applying protective adhesive agents, preventing damage during weaving and improving dye absorption. In contrast, desizing removes these sizing agents after weaving to restore fabric absorbency for finishing processes. Understanding sizing's objectives ensures your textile maintains durability and quality throughout production while facilitating effective dyeing and finishing treatments.

Common Sizing Agents and Their Properties

Common sizing agents include starch, polyvinyl alcohol (PVA), and acrylates, each offering unique film-forming and adhesive properties that enhance fabric strength and reduce fuzzing during weaving. Starch is favored for its biodegradability and excellent adhesion, while PVA provides superior water resistance and flexibility. Your choice of sizing agent impacts the efficiency of desizing, as agents like starch are easier to remove compared to synthetic polymers, influencing both fabric quality and environmental considerations.

Desizing: Meaning and Significance

Desizing is the crucial textile process of removing sizing agents applied to yarns before weaving, ensuring fabric softness and dye absorption quality. This step prevents weaving defects and enhances the final fabric's texture, making it essential for maintaining fabric performance. Proper desizing techniques directly impact Your textile production efficiency and product durability.

Methods of Desizing in Textile Industry

Desizing in the textile industry involves the removal of sizing agents applied to fabrics to improve weaving efficiency, with common methods including enzymatic, oxidative, acid, and hydrolytic desizing. Enzymatic desizing utilizes amylase enzymes to specifically break down starch-based sizes, offering eco-friendly and fabric-safe processing. Oxidative desizing employs oxidizing agents like hydrogen peroxide to degrade synthetic sizes, while acid and hydrolytic methods use acidic chemicals or high-temperature water to remove different sizing compounds effectively.

Key Differences Between Sizing and Desizing

Sizing involves applying a protective adhesive coating, typically starch or synthetic polymers, to fabric yarns to enhance strength, reduce breakage, and improve weaving efficiency. Desizing is the chemical or enzymatic removal of this sizing agent after weaving to ensure proper dyeing, finishing, and fabric softness. Key differences include sizing occurring before weaving to protect yarns, while desizing happens post-weaving to eliminate the sizing material for further processing.

Effects of Sizing and Desizing on Fabric Quality

Sizing enhances fabric strength and abrasion resistance by applying a protective adhesive coating, improving weaving efficiency and surface smoothness. Desizing removes these size materials, restoring fabric absorbency and softness, essential for subsequent dyeing and finishing processes. Improper desizing can result in residual sizing, causing uneven dye uptake and reduced fabric quality.

Environmental Considerations in Sizing and Desizing

Sizing in textile production often involves synthetic chemicals that can contribute to water pollution and high energy consumption during application and removal processes. Desizing, the process of removing sizing agents, typically requires substantial water usage and may produce wastewater with chemical residues, posing environmental challenges. Implementing eco-friendly sizing agents and enzymatic desizing methods can significantly reduce environmental impact by minimizing toxic effluents and conserving resources.

Future Trends and Innovations in Sizing and Desizing

Emerging trends in sizing and desizing focus on sustainable materials and eco-friendly enzymes that enhance fabric quality while reducing environmental impact. Innovations in nanotechnology and bio-based sizing agents improve fabric strength and water repellency without compromising breathability. You can expect integrated smart manufacturing systems that optimize sizing and desizing processes for increased efficiency and reduced chemical usage.

Sizing vs Desizing Infographic

libmatt.com

libmatt.com