Shuttleless looms operate faster and produce higher fabric quality by using modern technology like air-jet or rapier mechanisms, whereas shuttle looms rely on a traditional shuttle that weaves thread back and forth, resulting in slower production and more noise. Your choice depends on factors such as production speed, fabric type, and cost efficiency, with shuttleless looms favored for mass production and shuttle looms suited for specialized, intricate designs.

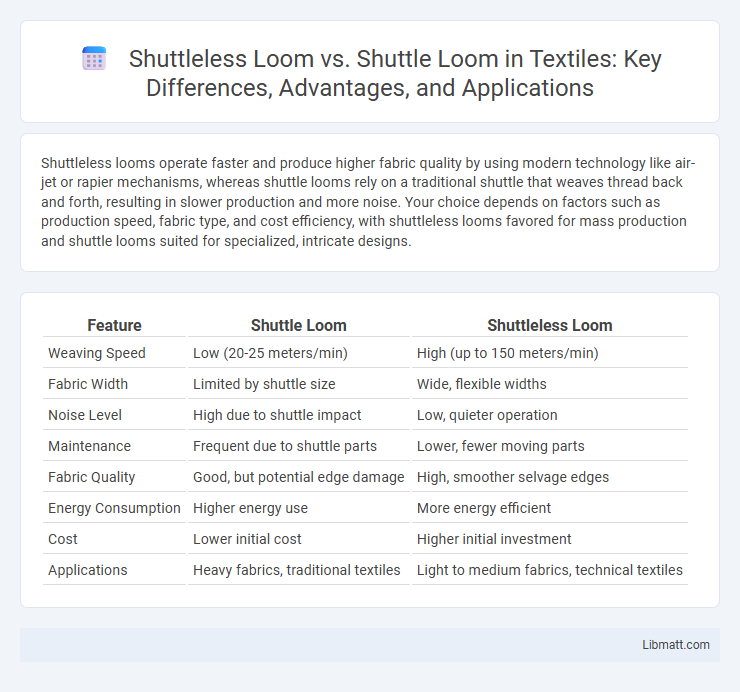

Table of Comparison

| Feature | Shuttle Loom | Shuttleless Loom |

|---|---|---|

| Weaving Speed | Low (20-25 meters/min) | High (up to 150 meters/min) |

| Fabric Width | Limited by shuttle size | Wide, flexible widths |

| Noise Level | High due to shuttle impact | Low, quieter operation |

| Maintenance | Frequent due to shuttle parts | Lower, fewer moving parts |

| Fabric Quality | Good, but potential edge damage | High, smoother selvage edges |

| Energy Consumption | Higher energy use | More energy efficient |

| Cost | Lower initial cost | Higher initial investment |

| Applications | Heavy fabrics, traditional textiles | Light to medium fabrics, technical textiles |

Introduction to Loom Technology

Shuttleless looms revolutionize textile production by employing air jets, water jets, rapier, or projectile mechanisms to insert weft yarns, enhancing speed and efficiency compared to traditional shuttle looms that use a shuttle to pass the weft thread through the warp. Shuttle looms, known for their simple design and broader fabric widths, provide high-quality selvage but operate at slower speeds and require more maintenance due to the shuttle's mechanical movements. Your choice between shuttleless and shuttle looms depends on factors like fabric type, production volume, and desired speed, influencing overall weaving technology integration.

Overview of Shuttle Looms

Shuttle looms use a traditional method where a shuttle carries the weft yarn back and forth through the warp threads to create fabric, resulting in slower weaving speeds but producing strong and durable textiles. These looms are mechanical and rely on the physical movement of the shuttle, which can cause more noise and wear over time compared to shuttleless looms. Understanding shuttle loom operations helps you appreciate their role in crafting high-quality woven materials despite advances in faster, more efficient shuttleless alternatives.

Overview of Shuttleless Looms

Shuttleless looms, including air-jet, water-jet, rapier, and projectile looms, revolutionize weaving by eliminating the traditional shuttle, enhancing fabric production speed and efficiency. These looms use alternative weft insertion methods such as air streams, water jets, or mechanical rapiers, which significantly reduce noise and increase machine uptime compared to conventional shuttle looms. The advanced technology in shuttleless looms supports a wide range of fabric types and is preferred in modern textile manufacturing for high-volume and high-quality output.

Key Differences Between Shuttle and Shuttleless Looms

Shuttle looms use a traditional shuttle to weave weft yarns through the warp, resulting in slower speeds and limited production efficiency, whereas shuttleless looms utilize alternative weft insertion methods like air jets, rapier, or water jets for faster and more versatile weaving. Shuttleless looms offer higher productivity, less noise, and lower maintenance due to fewer moving parts compared to the mechanically complex shuttles. The choice between shuttle and shuttleless looms depends on fabric type, production volume, and cost-effectiveness for specific textile applications.

Weaving Speed and Productivity Comparison

Shuttleless looms offer significantly higher weaving speed and productivity compared to shuttle looms, producing fabric at rates up to 800-1000 picks per minute, whereas traditional shuttle looms typically operate around 60-200 picks per minute. The continuous and non-stop operation in shuttleless looms reduces downtime and increases output, making them ideal for large-scale textile manufacturing. Your choice of loom can greatly impact production efficiency and fabric quality, with shuttleless technology providing a more advanced solution for high-speed weaving.

Fabric Quality and Versatility

Shuttleless looms produce fabric with more uniform tension and fewer defects, resulting in higher fabric quality and smoother surfaces compared to traditional shuttle looms. The technology in shuttleless looms allows for greater versatility, enabling the weaving of a wide range of complex patterns and materials with faster production speeds. Your choice of shuttleless loom enhances efficiency and fabric consistency, while shuttle looms may be preferred for specific traditional or artisanal textile applications.

Energy Efficiency and Operational Costs

Shuttleless looms consume significantly less energy compared to traditional shuttle looms due to their faster weaving speeds and reduced mechanical complexity, leading to lower operational costs. The optimized energy use of shuttleless looms contributes to decreased electricity bills and maintenance expenses, enhancing overall cost-efficiency in textile production. Conversely, shuttle looms, with higher friction and slower speeds, require more power and frequent repairs, resulting in increased energy consumption and operational expenditures.

Maintenance and Durability

Shuttleless looms require less frequent maintenance due to fewer moving parts and advanced technology, resulting in lower downtime and operational costs. Shuttle looms have higher wear and tear from the shuttle mechanism, demanding regular maintenance to ensure durability and consistent fabric quality. Overall, shuttleless looms offer enhanced durability and longer service life compared to the traditional shuttle looms.

Environmental Impact of Each Loom Type

Shuttleless looms generate less environmental impact compared to shuttle looms due to higher energy efficiency and reduced oil consumption during operation. Shuttleless looms produce less noise and lower emissions, minimizing workplace pollution and contributing to a cleaner production environment. The faster weaving speeds and automated processes of shuttleless looms also lead to decreased waste of raw materials and lower carbon footprints in textile manufacturing.

Choosing the Right Loom for Textile Production

Shuttleless looms offer higher weaving speed and greater efficiency compared to traditional shuttle looms, making them ideal for mass textile production and reducing labor costs. Shuttle looms provide superior fabric quality and handle heavy or intricate weaving patterns, preferred for specialized or artisanal textile products. Selecting the right loom depends on production volume, fabric complexity, and cost-effectiveness, with shuttleless looms favored for high-volume industrial output and shuttle looms suited for premium or niche textiles.

Shuttleless loom vs Shuttle loom Infographic

libmatt.com

libmatt.com