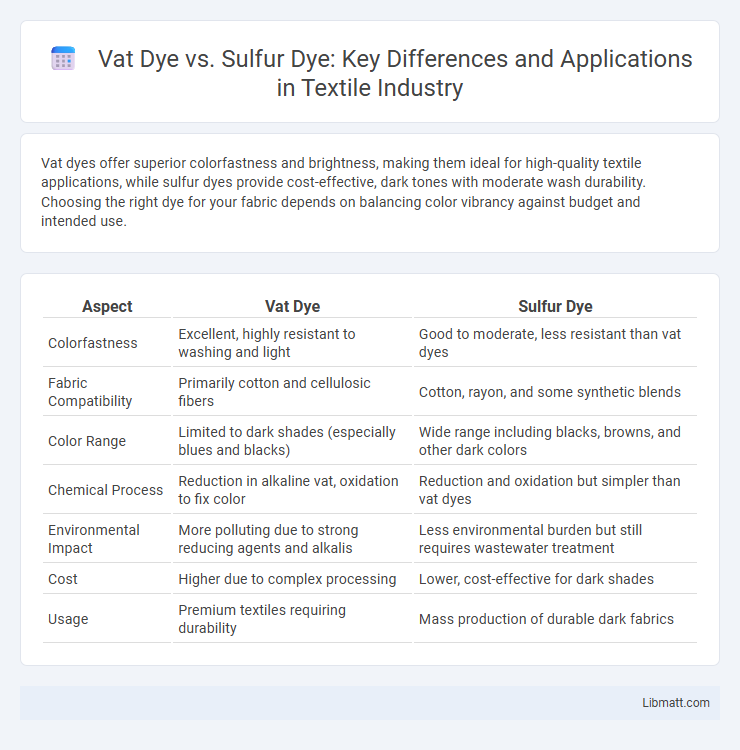

Vat dyes offer superior colorfastness and brightness, making them ideal for high-quality textile applications, while sulfur dyes provide cost-effective, dark tones with moderate wash durability. Choosing the right dye for your fabric depends on balancing color vibrancy against budget and intended use.

Table of Comparison

| Aspect | Vat Dye | Sulfur Dye |

|---|---|---|

| Colorfastness | Excellent, highly resistant to washing and light | Good to moderate, less resistant than vat dyes |

| Fabric Compatibility | Primarily cotton and cellulosic fibers | Cotton, rayon, and some synthetic blends |

| Color Range | Limited to dark shades (especially blues and blacks) | Wide range including blacks, browns, and other dark colors |

| Chemical Process | Reduction in alkaline vat, oxidation to fix color | Reduction and oxidation but simpler than vat dyes |

| Environmental Impact | More polluting due to strong reducing agents and alkalis | Less environmental burden but still requires wastewater treatment |

| Cost | Higher due to complex processing | Lower, cost-effective for dark shades |

| Usage | Premium textiles requiring durability | Mass production of durable dark fabrics |

Introduction to Vat Dye and Sulfur Dye

Vat dye and sulfur dye are two major classes of fiber-reactive dyes commonly used for dyeing cotton and other cellulosic fibers. Vat dyes, such as indigo, are water-insoluble pigments that become soluble through a reduction process and then oxidize to their original insoluble form on the fiber, offering excellent colorfastness and wash durability. Sulfur dyes involve a chemical reaction with sulfur compounds to form the dye, generally producing dark, muted shades with good lightfastness and high resistance to washing, widely applied in textile industries for cost-effective coloring.

Chemical Structure and Composition

Vat dyes are characterized by their insoluble chemical structure, primarily consisting of large, stable polycyclic molecules that undergo reduction to become soluble during the dyeing process. Sulfur dyes feature a complex composition containing sulfur linkages within aromatic rings, which form insoluble compounds upon oxidation on the fabric. Understanding these distinct chemical structures helps you choose the appropriate dye for specific textile applications based on colorfastness and fiber compatibility.

Dyeing Process Differences

Vat dyeing involves a chemical reduction process that makes the dye soluble for fabric absorption before oxidizing it back to its insoluble form, resulting in excellent colorfastness and durability. Sulfur dyeing uses heat to fix the dye through a chemical reaction that typically produces darker, more muted colors but offers less wash fastness compared to vat dyes. Your choice between these two will impact the fiber type compatibility and the intensity of the color achieved during the dyeing process.

Color Range and Fastness Properties

Vat dyes offer an extensive color range with brilliant and vibrant hues, known for exceptional colorfastness to washing, light, and rubbing, making them ideal for durable, long-lasting fabrics. Sulfur dyes provide a more limited palette, primarily earthy and darker tones, yet exhibit good fastness to washing and light, although they may have slightly lower resistance to rubbing compared to vat dyes. Your choice between vat dye and sulfur dye should consider the desired color intensity and the required durability of the fabric in its end use.

Environmental Impact and Sustainability

Vat dye offers higher environmental sustainability as it requires less water and produces minimal toxic waste during the dyeing process, compared to sulfur dye, which often generates harmful sulfur compounds and wastewater pollutants. Your choice of vat dye contributes to reducing environmental pollution and conserving resources, making it a more eco-friendly option. Sulfur dyes are more commonly associated with soil and water contamination, highlighting the importance of selecting dyes with lower ecological footprints for sustainable textile production.

Application Methods and Textile Compatibility

Vat dyes are primarily applied through a reduction and oxidation process, making them ideal for cellulose fibers such as cotton due to their excellent colorfastness and resistance to washing. Sulfur dyes use a simplified dyeing method involving alkaline conditions and high-temperature fixation, which works best on cellulosic textiles but offers less colorfastness compared to vat dyes. Both dye types are compatible with cotton, yet vat dyes provide deeper, more durable hues while sulfur dyes are preferred for cost-effective, dark-colored fabrics.

Cost Comparison and Economic Factors

Vat dyes generally incur higher initial costs due to complex manufacturing and application processes but offer superior colorfastness and durability, lowering long-term expenses for re-dyeing and maintenance. Sulfur dyes are more economical upfront, with simpler and less costly production, making them ideal for bulk textile production and budget-conscious markets despite their lower wash and light fastness. Economic choice between vat and sulfur dyes depends on balancing immediate budget constraints against the desired longevity and quality of fabric coloration.

Advantages of Vat Dye

Vat dyes offer superior colorfastness, making them highly resistant to washing, light, and perspiration, which ensures long-lasting vibrant colors on fabrics. Their excellent affinity for cellulose fibers like cotton results in deep, rich shades that do not fade easily, enhancing the durability of textiles. Vat dyes also exhibit excellent chemical and abrasion resistance, making them ideal for heavy-duty applications in industrial and fashion textiles.

Advantages of Sulfur Dye

Sulfur dyes offer excellent cost-effectiveness and provide good colorfastness, particularly in dark shades like black and brown, making them ideal for heavy-duty fabrics. These dyes exhibit strong resistance to washing, light, and perspiration, ensuring durability in workwear and upholstery applications. Their straightforward application process requires less specialized equipment compared to vat dyes, enhancing productivity in large-scale textile manufacturing.

Choosing the Right Dye: Key Considerations

Choosing the right dye between vat dye and sulfur dye depends on factors such as fabric type, colorfastness requirements, and environmental impact. Vat dyes offer superior wash and light fastness, making them ideal for high-quality cotton textiles, while sulfur dyes provide cost-effective dyeing for darker shades with moderate fastness. You should evaluate your project's durability needs and sustainability goals to determine the optimal dye choice.

Vat Dye vs Sulfur Dye Infographic

libmatt.com

libmatt.com