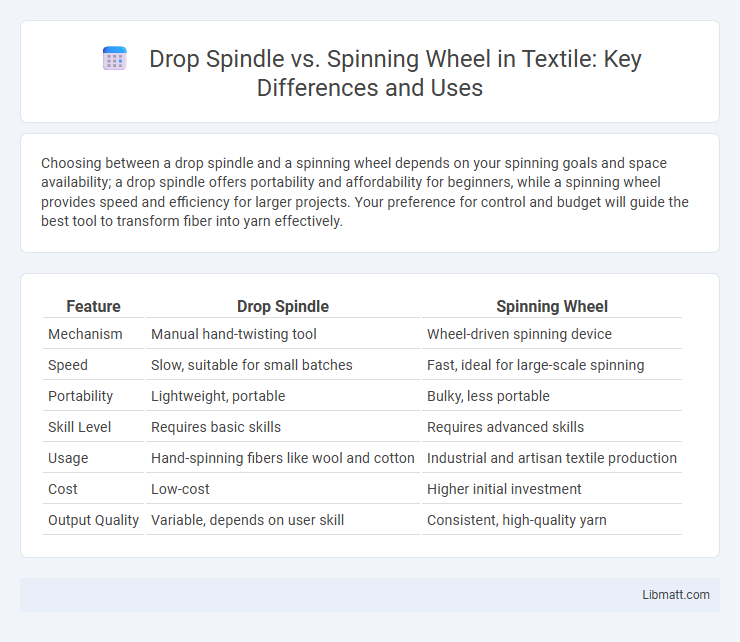

Choosing between a drop spindle and a spinning wheel depends on your spinning goals and space availability; a drop spindle offers portability and affordability for beginners, while a spinning wheel provides speed and efficiency for larger projects. Your preference for control and budget will guide the best tool to transform fiber into yarn effectively.

Table of Comparison

| Feature | Drop Spindle | Spinning Wheel |

|---|---|---|

| Mechanism | Manual hand-twisting tool | Wheel-driven spinning device |

| Speed | Slow, suitable for small batches | Fast, ideal for large-scale spinning |

| Portability | Lightweight, portable | Bulky, less portable |

| Skill Level | Requires basic skills | Requires advanced skills |

| Usage | Hand-spinning fibers like wool and cotton | Industrial and artisan textile production |

| Cost | Low-cost | Higher initial investment |

| Output Quality | Variable, depends on user skill | Consistent, high-quality yarn |

Introduction to Hand Spinning Tools

Hand spinning tools like drop spindles and spinning wheels are essential for transforming raw fibers into yarn. Drop spindles are lightweight, portable, and ideal for beginners, allowing precise control over fiber twist and yarn thickness. Spinning wheels offer faster production and greater efficiency, making them preferred for larger projects and professional spinners.

What is a Drop Spindle?

A drop spindle is a handheld tool used for spinning fibers into yarn by twisting and winding, ideal for small-scale or portable fiber crafting. Compared to a spinning wheel, the drop spindle is more compact, affordable, and requires less space, making it perfect for beginners and those who spin occasionally. Your choice depends on the volume and consistency of yarn you want to produce, with the spindle offering a traditional, tactile spinning experience.

What is a Spinning Wheel?

A spinning wheel is a mechanical device used to spin fibers into yarn or thread, featuring a large wheel that is turned by hand or foot to twist raw fibers such as wool, flax, or cotton. Unlike the drop spindle, which is a portable, handheld tool relying on manual twisting, the spinning wheel increases efficiency by maintaining consistent tension and speed during the spinning process. Its invention revolutionized textile production by enabling faster yarn creation and improving thread uniformity for weaving and knitting.

Historical Development of Drop Spindles and Spinning Wheels

Drop spindles have been used since ancient times, dating back to the Neolithic era, as one of the earliest tools for spinning fibers into thread. Spinning wheels were developed later, around the 11th century in India, revolutionizing textile production by significantly increasing spinning speed and efficiency. Your understanding of these tools highlights the shift from manual to mechanized spinning technology that shaped the textile industry's evolution.

Portability and Space Considerations

Drop spindles are highly portable due to their compact size and lightweight design, making them ideal for on-the-go spinning and small storage spaces. Spinning wheels tend to be larger and heavier, requiring dedicated floor space and a stationary setup for operation. For crafters with limited room or those who travel frequently, drop spindles offer greater convenience without sacrificing the ability to create quality yarn.

Speed and Yarn Production Efficiency

Drop spindles produce yarn at a slower pace, suitable for small-scale or hobby spinning, with limited yarn output per hour compared to spinning wheels. Spinning wheels significantly increase yarn production efficiency, offering higher rotational speeds and continuous feed mechanisms that enable spinners to produce consistent, uniform yarn quickly. The enhanced speed and mechanical advantage of spinning wheels make them ideal for large batches and professional textile applications.

Learning Curve and User Techniques

Drop spindles have a gentler learning curve, making them ideal for beginners to practice basic spinning techniques such as drafting and twisting fibers. Spinning wheels require more coordination and technique, including treadling and managing multiple moving parts, which can challenge new users but increase efficiency and consistency once mastered. Your choice depends on whether you prefer a slower, hands-on learning experience or aim for faster production with advanced skills.

Types of Yarn Produced: Drop Spindle vs Spinning Wheel

Drop spindles produce fine, consistent yarn ideal for lightweight projects and detailed work, while spinning wheels create a wider range of yarn types, from fine to bulky, allowing for greater versatility in texture and thickness. Your choice influences yarn durability and twist density, with drop spindles often yielding softer, more delicate strands and spinning wheels providing stronger, more uniform yarn. Understanding these differences helps in selecting the appropriate tool for your desired knitting or weaving project.

Cost and Investment Comparison

Drop spindles require minimal investment, often costing under $20, making them highly affordable for beginners or hobbyists. In contrast, spinning wheels represent a significant financial commitment, with prices ranging from $200 to over $1,000, depending on the model, brand, and features. The lower upfront cost of drop spindles makes them ideal for those exploring fiber arts, while spinning wheels offer greater efficiency and long-term value for dedicated spinners.

Choosing the Right Tool for Your Spinning Needs

Selecting between a drop spindle and a spinning wheel depends on your spinning goals, space, and budget. Drop spindles offer portability and affordability, ideal for beginners or small-scale projects, while spinning wheels provide greater speed and efficiency suited for larger quantities of yarn. Assess your fiber type, desired yarn thickness, and production volume to determine the best tool that aligns with your crafting needs.

Drop spindle vs Spinning wheel Infographic

libmatt.com

libmatt.com