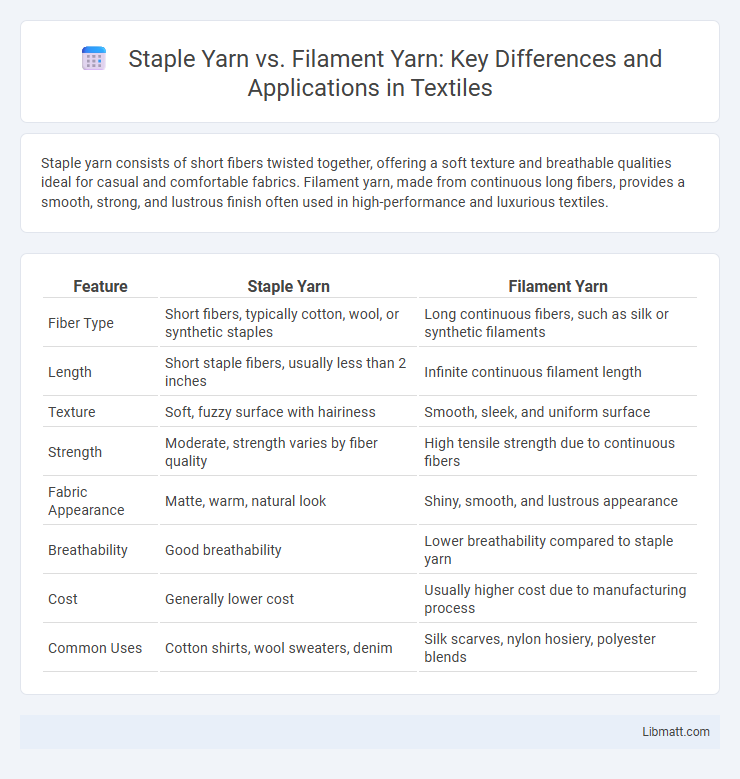

Staple yarn consists of short fibers twisted together, offering a soft texture and breathable qualities ideal for casual and comfortable fabrics. Filament yarn, made from continuous long fibers, provides a smooth, strong, and lustrous finish often used in high-performance and luxurious textiles.

Table of Comparison

| Feature | Staple Yarn | Filament Yarn |

|---|---|---|

| Fiber Type | Short fibers, typically cotton, wool, or synthetic staples | Long continuous fibers, such as silk or synthetic filaments |

| Length | Short staple fibers, usually less than 2 inches | Infinite continuous filament length |

| Texture | Soft, fuzzy surface with hairiness | Smooth, sleek, and uniform surface |

| Strength | Moderate, strength varies by fiber quality | High tensile strength due to continuous fibers |

| Fabric Appearance | Matte, warm, natural look | Shiny, smooth, and lustrous appearance |

| Breathability | Good breathability | Lower breathability compared to staple yarn |

| Cost | Generally lower cost | Usually higher cost due to manufacturing process |

| Common Uses | Cotton shirts, wool sweaters, denim | Silk scarves, nylon hosiery, polyester blends |

Introduction to Staple Yarn and Filament Yarn

Staple yarn consists of short fibers twisted together, commonly made from natural fibers like cotton or synthetic fibers cut to a similar length. Filament yarn, in contrast, is composed of long continuous fibers such as silk, polyester, or nylon, which can be smooth or textured. The fundamental difference lies in fiber length, influencing the yarn's texture, strength, and applications in textiles.

Definition of Staple Yarn

Staple yarn consists of short fibers twisted together to form a continuous thread, typically measuring a few inches in length. These fibers come from natural sources like cotton or wool, or synthetic fibers cut into short lengths. Understanding the definition of staple yarn helps you distinguish it from filament yarn, which is made from long continuous fibers.

Definition of Filament Yarn

Filament yarn consists of continuous fibers spun together, offering smoothness and strength ideal for high-quality fabrics. Unlike staple yarn, which is made from short fiber lengths twisted, filament yarn's long, unbroken filaments reduce pilling and enhance durability. Common materials for filament yarn include silk, polyester, and nylon, widely used in textiles requiring a glossy finish and uniform texture.

Raw Materials Used in Staple and Filament Yarns

Staple yarn is produced from short fibers such as cotton, wool, or flax, which are naturally short and require spinning to form continuous threads. Filament yarn consists of long, continuous fibers made from synthetic materials like polyester, nylon, or silk, or naturally occurring fibers like silk. The difference in raw materials influences the yarn's texture, strength, and end-use applications in textiles and industrial fabrics.

Manufacturing Processes Compared

Staple yarn is made by spinning short fibers, such as cotton or wool, which are carded and combed before being twisted into yarn, resulting in a textured and less uniform surface. Filament yarn consists of continuous fibers, often synthetic like polyester or nylon, produced through extrusion processes where molten polymers are drawn and cooled into long filaments with smooth, consistent texture. Understanding these manufacturing processes helps you select the right yarn type based on desired fabric strength, appearance, and end-use applications.

Physical Properties: Staple vs Filament Yarns

Staple yarns consist of short fiber lengths twisted together, resulting in a softer texture and higher propensity for pilling due to fiber ends protruding from the yarn surface. Filament yarns are made from continuous long fibers that provide a smooth, strong, and lustrous appearance with increased resistance to abrasion and minimal fuzziness. Your choice between staple and filament yarns should consider the desired texture, strength, and durability required for the final textile product.

Performance and Durability Differences

Staple yarn, composed of short fibers twisted together, offers greater elasticity and warmth but is less durable due to fiber ends causing friction and wear. Filament yarn consists of continuous fibers, providing superior strength, smoothness, and abrasion resistance, resulting in enhanced durability and performance in high-stress applications. Performance differences include staple yarn's tendency to pill and degrade faster, while filament yarn maintains structural integrity and color retention over time.

Common Applications in Textiles

Staple yarns, made from short fibers like cotton or wool, are commonly used in apparel, home textiles, and upholstery due to their softness and warmth. Filament yarns, composed of continuous fibers such as polyester or silk, are ideal for high-strength fabrics found in sportswear, industrial textiles, and lingerie. Understanding the distinct applications helps you select the appropriate yarn type for performance and texture in textile products.

Advantages and Disadvantages of Each Yarn Type

Staple yarn, composed of short fibers twisted together, offers advantages like softness, warmth, and easy dye absorption but may have less strength and durability compared to filament yarn. Filament yarn, made from continuous filament fibers, excels in strength, smooth texture, and resistance to pilling, yet it can feel less breathable and lacks the elasticity of staple yarn. Understanding these differences helps you choose the right yarn for your textile project based on desired fabric qualities and performance.

Choosing the Right Yarn: Staple or Filament?

Choosing between staple yarn and filament yarn depends on your project's desired texture, strength, and appearance; staple yarn consists of short fibers spun together for a soft, breathable fabric, while filament yarn uses long continuous fibers for smoothness and durability. Staple yarn is ideal for cozy clothing and textiles requiring warmth, whereas filament yarn excels in producing sleek, strong materials like linings and performance wear. Your choice will affect the fabric's hand feel, durability, and suitability for specific applications.

Staple Yarn vs Filament Yarn Infographic

libmatt.com

libmatt.com