Yarn slubbing refers to the intentional creation of thick, uneven segments along the yarn to add texture and visual interest, while yarn nepping involves small, knotted clusters or lumps caused by short fiber entanglements. Understanding the difference between yarn slubbing and nepping helps you choose the right yarn for achieving the desired fabric texture and appearance.

Table of Comparison

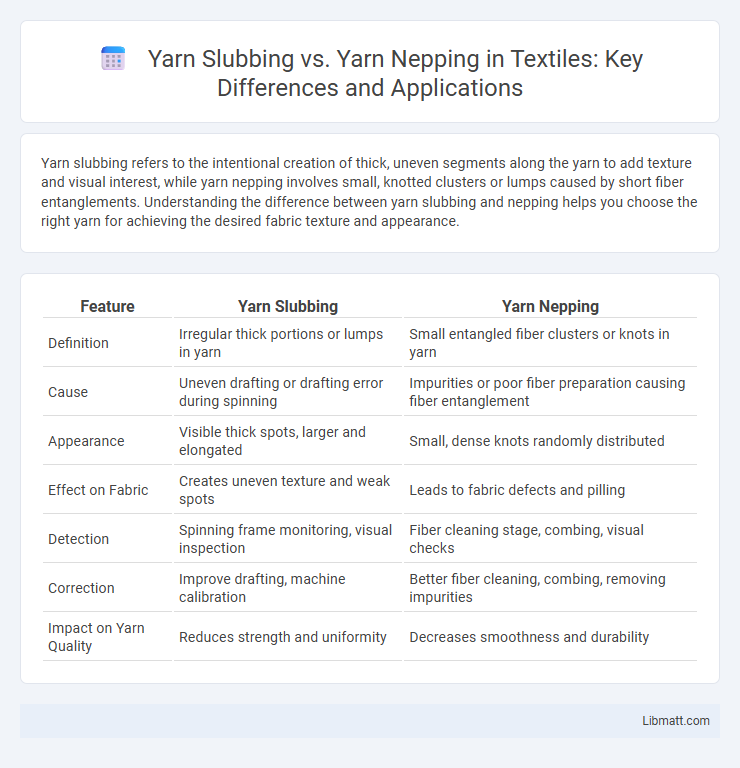

| Feature | Yarn Slubbing | Yarn Nepping |

|---|---|---|

| Definition | Irregular thick portions or lumps in yarn | Small entangled fiber clusters or knots in yarn |

| Cause | Uneven drafting or drafting error during spinning | Impurities or poor fiber preparation causing fiber entanglement |

| Appearance | Visible thick spots, larger and elongated | Small, dense knots randomly distributed |

| Effect on Fabric | Creates uneven texture and weak spots | Leads to fabric defects and pilling |

| Detection | Spinning frame monitoring, visual inspection | Fiber cleaning stage, combing, visual checks |

| Correction | Improve drafting, machine calibration | Better fiber cleaning, combing, removing impurities |

| Impact on Yarn Quality | Reduces strength and uniformity | Decreases smoothness and durability |

Introduction to Yarn Slubbing and Nepping

Yarn slubbing refers to the intentional creation of thick and thin sections along the yarn, giving it a textured, uneven appearance that enhances fabric aesthetics and tactile feel. Nepping involves small, entangled fiber clusters or knots woven into the yarn, contributing to a unique surface texture and a distinctive visual effect in textiles. Understanding the differences between yarn slubbing and yarn nepping can help you choose the right yarn type for your specific fabric design and desired texture.

Defining Yarn Slubbing

Yarn slubbing refers to the intentional creation of irregular thick and thin sections within a yarn, resulting in a textured appearance that adds dimensionality and visual interest to woven or knitted fabrics. This technique differs from yarn nepping, which involves small, tangled fiber lumps embedded in the yarn, usually formed unintentionally during processing and affecting fabric smoothness. Yarn slubbing enhances fabric aesthetics and tactile qualities, making it popular in fashion textiles and decorative applications.

Understanding Yarn Nepping

Yarn nepping occurs when small knots or clusters of fibers form during the spinning or weaving process, creating textured irregularities in the yarn. These neps can affect the fabric's appearance and strength, often leading to a more rustic or artisanal look, which might be desirable or a defect depending on the intended textile quality. Understanding yarn nepping helps you control and select yarns that meet your specific design and durability requirements.

Key Differences Between Slubbing and Nepping

Yarn slubbing produces thick, uneven sections along the yarn length, resulting from intentional irregular twist during spinning, while yarn nepping involves small, tangled fiber clusters or knots embedded within the yarn. Slubbing affects yarn texture by creating elongated thick spots, enhancing fabric aesthetics and adding character, whereas nepping impacts yarn quality by causing undesirable small lumps that can weaken the fabric. Your choice between slubbing and nepping processes directly influences the fabric's appearance and performance, with slubbing favored for decorative effects and nepping commonly considered a defect to minimize.

Causes of Yarn Slubbing

Yarn slubbing occurs primarily due to inconsistencies in the spinning process, such as uneven fiber drafting or improper tension control, leading to thicker, uneven sections within the yarn. This defect is often caused by irregularities in fiber length, moisture content, or machine settings that disrupt the smooth flow of fibers. Addressing these factors in your spinning operation can significantly improve yarn uniformity and reduce slubbing.

Factors Leading to Yarn Nepping

Yarn nepping occurs due to fiber entanglement and variations in fiber length, leading to small knots or lumps in the fabric that affect texture and strength. Factors such as high humidity, improper fiber blending, and inadequate carding or combing processes contribute to increased nep formation. Controlling fiber quality and maintaining precise machinery settings are essential to minimize yarn nepping and ensure your fabric's smoothness and durability.

Impact on Fabric Appearance and Texture

Yarn slubbing creates intentional thick and thin segments, resulting in a textured fabric with a visually varied surface that adds character and a handcrafted feel. Yarn nepping introduces small knots or lumps that produce a speckled, uneven texture, contributing to a rustic or vintage aesthetic while potentially affecting fabric smoothness. Your choice between slubbing and nepping impacts the fabric's tactile experience and visual interest, influencing garment style and fabric performance.

Applications and Uses in Textile Industry

Yarn slubbing is primarily used in decorative fabrics and casual apparel to create textured, uneven yarns that enhance the aesthetic appeal in products like denim and upholstery fabrics. Yarn nepping introduces small, irregular knots or tufts, ideal for producing tweed and boucle fabrics that require a rustic or boucle texture, frequently used in suits and outerwear. Both techniques contribute unique tactile and visual effects, influencing fabric durability and design versatility in the textile manufacturing process.

Quality Control for Slubbed and Nepped Yarns

Quality control for slubbed yarn involves monitoring the intentional variations in thickness and texture to ensure consistent slub placement and size, preserving the desired aesthetic without compromising fabric performance. In contrast, quality control for nepped yarn targets the detection and removal of unwanted small fiber entanglements (neps) that can cause defects in the final textile, focusing on uniformity and smoothness. Your quality assurance processes should distinguish between these techniques to maintain the balance between intentional yarn character and overall fabric quality.

Choosing the Right Yarn: Slubbing vs Nepping

Choosing the right yarn involves understanding the differences between yarn slubbing and yarn nepping, which directly impact fabric texture and appearance. Yarn slubbing features intentional thick and thin sections, creating a unique, uneven texture ideal for rustic or artisanal textiles. In contrast, yarn nepping incorporates small, tangled clusters that produce a speckled, nubby effect, often used to add visual interest and tactile complexity to blends or tweeds.

Yarn Slubbing vs Yarn Nepping Infographic

libmatt.com

libmatt.com