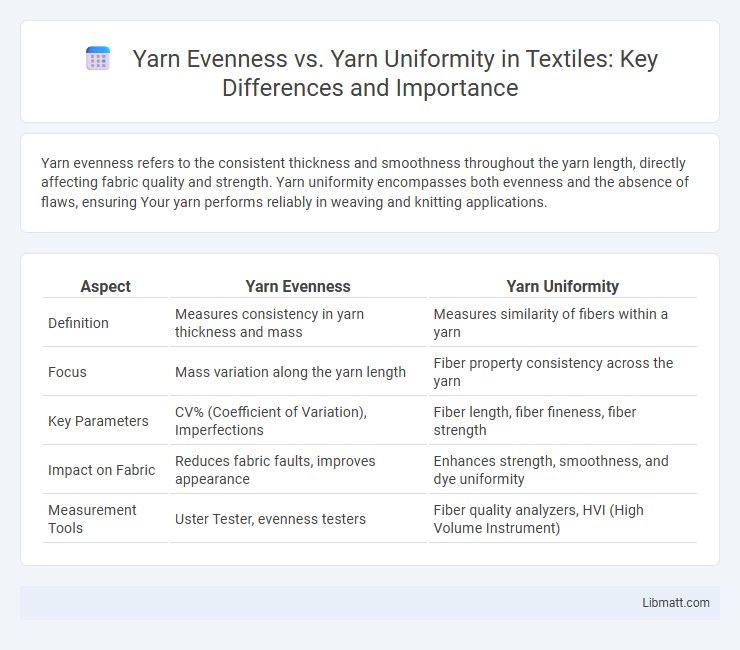

Yarn evenness refers to the consistent thickness and smoothness throughout the yarn length, directly affecting fabric quality and strength. Yarn uniformity encompasses both evenness and the absence of flaws, ensuring Your yarn performs reliably in weaving and knitting applications.

Table of Comparison

| Aspect | Yarn Evenness | Yarn Uniformity |

|---|---|---|

| Definition | Measures consistency in yarn thickness and mass | Measures similarity of fibers within a yarn |

| Focus | Mass variation along the yarn length | Fiber property consistency across the yarn |

| Key Parameters | CV% (Coefficient of Variation), Imperfections | Fiber length, fiber fineness, fiber strength |

| Impact on Fabric | Reduces fabric faults, improves appearance | Enhances strength, smoothness, and dye uniformity |

| Measurement Tools | Uster Tester, evenness testers | Fiber quality analyzers, HVI (High Volume Instrument) |

Introduction to Yarn Evenness and Uniformity

Yarn evenness measures the consistency of yarn thickness along its length, impacting fabric appearance and strength, while yarn uniformity assesses the distribution of fiber mass within the yarn cross-section, affecting durability and texture. Both yarn evenness and uniformity are crucial quality parameters in textile production, ensuring optimal fabric performance and visual appeal. Understanding these characteristics helps you select and produce high-quality yarns tailored to specific applications.

Defining Yarn Evenness

Yarn evenness refers to the consistency in the thickness or diameter of the yarn along its entire length, which directly impacts fabric appearance and strength. Unlike yarn uniformity, which measures the overall homogeneity of fiber distribution, evenness focuses specifically on variations in mass per unit length. You can improve yarn quality by controlling production processes to minimize unevenness, resulting in smoother fabrics and better performance.

Understanding Yarn Uniformity

Yarn uniformity refers to the consistency of yarn thickness and texture throughout its length, directly affecting fabric quality and appearance. Unlike yarn evenness, which measures variations in yarn diameter, uniformity encompasses both the size and distribution of fibers, ensuring strength and smoothness. Understanding yarn uniformity helps you select yarns that provide better durability and a more refined finished product.

Key Differences Between Yarn Evenness and Uniformity

Yarn evenness measures the consistency of yarn thickness along its length, typically assessed using parameters like CV% (coefficient of variation) to identify thin or thick spots. Yarn uniformity refers to the overall homogeneity in yarn structure, including fiber distribution and twist consistency, impacting fabric strength and appearance. Key differences lie in their focus areas: evenness targets variation in linear density, while uniformity encompasses broader structural consistency of the yarn.

Importance of Yarn Evenness in Textile Manufacturing

Yarn evenness plays a critical role in textile manufacturing by ensuring consistent fabric quality, reducing defects, and improving the overall strength and appearance of the final product. Uneven yarn can cause irregularities such as thick and thin spots, leading to weaving problems and compromised fabric performance. Superior yarn evenness enhances efficiency in production processes and results in textiles with uniform texture and durability.

Role of Yarn Uniformity in Fabric Quality

Yarn uniformity critically impacts fabric quality by ensuring consistent thickness and tensile strength throughout the yarn, which reduces defects in the final textile product. High yarn uniformity minimizes irregularities like thick and thin spots, leading to smoother fabric surfaces, improved appearance, and enhanced durability. This consistency supports better weaving performance and results in fabrics with superior hand feel and visual appeal.

Factors Affecting Yarn Evenness

Yarn evenness is primarily influenced by fiber quality, spinning tension, and machine settings, which determine the consistency of yarn thickness throughout its length. Variations in fiber length, fineness, and impurities directly impact the uniformity, causing fluctuations that reduce yarn performance. Maintaining optimal humidity levels and regular equipment maintenance also play critical roles in minimizing yarn irregularities.

Factors Influencing Yarn Uniformity

Yarn uniformity is primarily influenced by fiber length distribution, spinning technology, and machine settings, which determine the consistency of yarn thickness and strength. Variations in fiber quality, such as maturity and fineness, directly impact the evenness of the yarn's surface, affecting its appearance and performance. Advanced control of drafting systems and tension in spinning machines reduces irregularities, enhancing overall yarn uniformity.

Methods for Measuring Yarn Evenness and Uniformity

Yarn evenness and uniformity are key indicators of yarn quality measured using advanced instruments such as the Uster Tester and Zweigle Yarn Evenness Tester. These devices employ capacitance, optical, or electrical resistance methods to detect variations in yarn thickness, providing detailed data on irregularities and defects. Your ability to analyze these measurements ensures consistent yarn performance and improved fabric strength.

Impact of Evenness and Uniformity on End-Use Performance

Yarn evenness and yarn uniformity critically influence the quality and performance of textile products. High yarn evenness minimizes thick and thin places, resulting in smoother fabric surfaces and better durability, while uniformity ensures consistent strength and appearance throughout the yarn, reducing defects in the final product. Your choice of yarn with optimal evenness and uniformity directly enhances fabric aesthetics, comfort, and wear resistance, essential for applications like apparel, upholstery, and technical textiles.

Yarn Evenness vs Yarn Uniformity Infographic

libmatt.com

libmatt.com