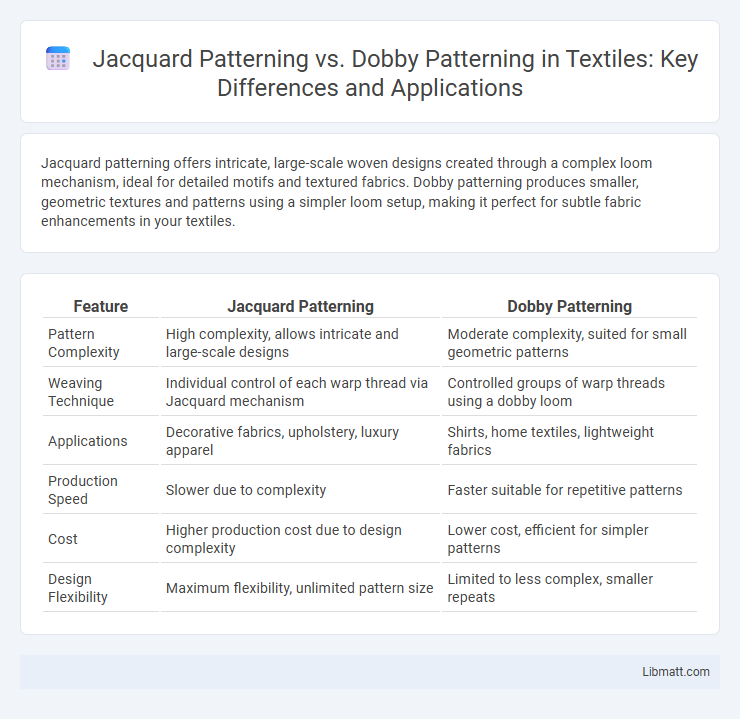

Jacquard patterning offers intricate, large-scale woven designs created through a complex loom mechanism, ideal for detailed motifs and textured fabrics. Dobby patterning produces smaller, geometric textures and patterns using a simpler loom setup, making it perfect for subtle fabric enhancements in your textiles.

Table of Comparison

| Feature | Jacquard Patterning | Dobby Patterning |

|---|---|---|

| Pattern Complexity | High complexity, allows intricate and large-scale designs | Moderate complexity, suited for small geometric patterns |

| Weaving Technique | Individual control of each warp thread via Jacquard mechanism | Controlled groups of warp threads using a dobby loom |

| Applications | Decorative fabrics, upholstery, luxury apparel | Shirts, home textiles, lightweight fabrics |

| Production Speed | Slower due to complexity | Faster suitable for repetitive patterns |

| Cost | Higher production cost due to design complexity | Lower cost, efficient for simpler patterns |

| Design Flexibility | Maximum flexibility, unlimited pattern size | Limited to less complex, smaller repeats |

Introduction to Jacquard and Dobby Patterning

Jacquard patterning utilizes a complex lifting mechanism to control individual warp threads, creating intricate and highly detailed designs often found in brocades and damasks. Dobby patterning, by contrast, employs a simpler mechanism that manipulates groups of warp threads, producing geometric and repetitive textures suitable for lightweight fabrics like shirtings and home textiles. Your choice between Jacquard and Dobby depends on the desired design complexity and fabric texture for your textile project.

Historical Evolution of Textile Patterning

Jacquard patterning revolutionized textile design in the early 19th century by introducing a punched card system that allowed complex, intricate patterns to be woven automatically, transforming the industry's capabilities. Dobby patterning, predating Jacquard, utilizes a simpler harness system to create small geometric designs, offering efficient versatility but with limited design complexity. Understanding the historical evolution from Dobby's functional simplicity to Jacquard's technological innovation highlights how your textile patterning options have expanded dramatically over time.

Jacquard Patterning: Definition and Key Features

Jacquard patterning is a weaving technique that utilizes a specialized loom with a punched card system or electronic control to create complex, intricate patterns directly into the fabric. Key features include the ability to produce detailed, large-scale designs with varied motifs, often seen in brocades, damasks, and tapestries, allowing for individual control of each warp thread. This sophisticated method offers unparalleled design versatility compared to simpler weaving techniques like dobby, making it ideal for high-end textiles where elaborate patterns and rich textures are desired.

Dobby Patterning: Definition and Core Characteristics

Dobby patterning is a weaving technique that produces small, geometric patterns and textured fabrics using a dobby loom with a controlled lifting mechanism for warp threads. It is distinguished by its ability to create intricate, repetitive motifs that are typically simpler and smaller in scale than those produced by Jacquard looms. Dobby weaving enhances fabric durability and aesthetic appeal by integrating varied weave structures such as honeycomb, waffle, and birdseye patterns.

Mechanisms and Technology: Jacquard vs Dobby

Jacquard patterning employs a sophisticated punched card or digital control system to individually manipulate each warp thread, enabling intricate and highly detailed fabric designs. In contrast, Dobby patterning uses a simpler harness loom with fewer shafts, creating geometric or small repeating patterns by lifting groups of warp threads simultaneously. The advanced mechanism of Jacquard allows for complex imagery and textures, while Dobby technology is optimized for simpler, repetitive motifs, making Jacquard ideal for elaborate textiles and Dobby for efficient production of basic patterns.

Design Complexity: Comparative Capabilities

Jacquard patterning enables highly intricate and detailed designs by controlling each warp thread individually, allowing for complex motifs with extensive color variations and fine textures. In contrast, Dobby patterning offers more limited design complexity, primarily producing geometric and repetitive patterns by manipulating small groups of warp threads. The superior capability of Jacquard looms to create elaborate and versatile textile designs makes them ideal for sophisticated fabric patterns compared to the simpler structures achievable with Dobby.

Fabric Applications: Jacquard vs Dobby Uses

Jacquard patterning specializes in complex, intricate designs such as florals, paisleys, and detailed motifs, making it ideal for luxurious fabrics used in upholstery, high-end fashion, and home textiles. Dobby patterning produces small, geometric, and repetitive textures, perfect for everyday apparel, shirting fabrics, and lightweight home furnishings. Your choice between Jacquard and Dobby depends on whether you need elaborate decorative aesthetics or subtle, textured patterns for functional fabric applications.

Production Efficiency and Costs

Jacquard patterning uses intricate, programmable mechanisms to create complex, multi-colored designs, which increases production time and costs compared to Dobby patterning that produces simpler geometric patterns with fewer yarns. Dobby looms have faster setup times and lower operational expenses, making them more cost-effective for mass production of fabrics with repetitive designs. Jacquard weaving demands higher initial investment and skilled labor, impacting overall efficiency especially in short production runs or lower volume orders.

Suitability for Various Textile Industries

Jacquard patterning excels in producing intricate and highly detailed designs, making it ideal for luxury fashion, upholstery, and decorative textiles where complex motifs are essential. Dobby patterning, characterized by geometric and small repetitive patterns, suits industries focused on lightweight apparel, home linens, and casual wear due to its efficiency and simplicity. Your choice between these techniques depends on the desired fabric complexity and the specific textile market requirements.

Choosing Between Jacquard and Dobby Patterning

Choosing between Jacquard and Dobby patterning depends on the complexity and scale of your fabric design. Jacquard patterning is ideal for intricate, large-scale motifs with multiple colors, offering high detail through programmable loom technology. Dobby patterning suits simpler geometric or small repeat patterns, providing textured effects with faster production and cost efficiency for your textile projects.

Jacquard patterning vs Dobby patterning Infographic

libmatt.com

libmatt.com