Padding mangle applies firm pressure to fabrics during ironing, ideal for smoothing out heavy or thick textiles, while foulard mangle uses a gentler rolling action suited for delicate, lightweight materials like silk or chiffon. Choosing the right mangle ensures your fabric maintains its texture and appearance without damage.

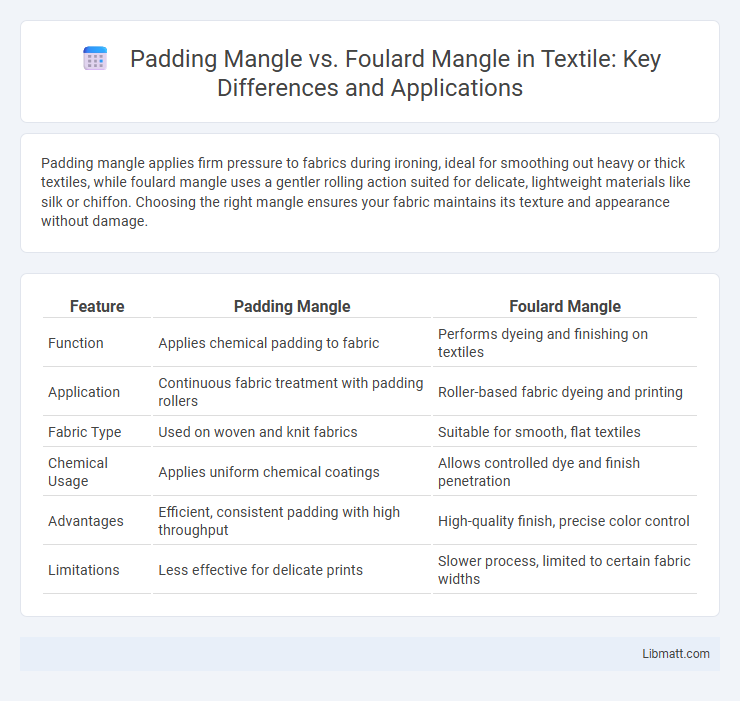

Table of Comparison

| Feature | Padding Mangle | Foulard Mangle |

|---|---|---|

| Function | Applies chemical padding to fabric | Performs dyeing and finishing on textiles |

| Application | Continuous fabric treatment with padding rollers | Roller-based fabric dyeing and printing |

| Fabric Type | Used on woven and knit fabrics | Suitable for smooth, flat textiles |

| Chemical Usage | Applies uniform chemical coatings | Allows controlled dye and finish penetration |

| Advantages | Efficient, consistent padding with high throughput | High-quality finish, precise color control |

| Limitations | Less effective for delicate prints | Slower process, limited to certain fabric widths |

Introduction to Mangling in Textile Finishing

Mangling in textile finishing involves pressing and smoothing fabrics to achieve a polished look and enhance texture. Padding mangles use rollers to apply liquid finishes uniformly, optimizing moisture control and fabric softness. Foulard mangles specialize in flattening printed or delicate fabrics without damaging patterns, preserving print quality and fabric integrity.

What is a Padding Mangle?

A Padding Mangle is a specialized machine used in textile finishing to apply a uniform layer of padding or thickening agents onto fabric surfaces, enhancing texture and durability. Its precise rollers and pressure controls ensure even distribution of liquids or resins, crucial for achieving desired fabric softness or stiffness in industries like upholstery and garment manufacturing. This equipment differs from a Foulard Mangle, which primarily smooths and polishes fabric through light pressure and heat without applying padding materials.

What is a Foulard Mangle?

A Foulard mangle is a specialized fabric finishing machine designed to impart a smooth, polished surface to delicate textiles like silk and wool. Unlike a Padding mangle, which primarily applies liquid finishes such as dyes or chemicals, a Foulard mangle uses pressure and heat without excess moisture to enhance fabric softness and sheen. Your choice between these machines depends on whether you need gentle fabric finishing or liquid application during textile processing.

Key Differences Between Padding Mangle and Foulard Mangle

Padding mangle applies pressure using a thick, padded roller to evenly distribute liquid or remove excess moisture from textiles, while foulard mangle uses a smoother roller to achieve a polished finish without heavy pressure. The main difference lies in their application: padding mangles are designed for impregnation and treatment of fabrics with chemicals or dyes, whereas foulard mangles focus on ironing and smoothing delicate materials such as silk or fine wool. Your choice depends on whether you need deep fabric treatment or gentle surface finishing.

Advantages of Using Padding Mangle

Padding mangle offers superior fabric softness and even application of chemicals, enhancing textile quality compared to foulard mangle. It provides better control over fabric tension and pressure, reducing damage while improving efficiency in fabric treatment processes. Your production benefits from faster processing speeds and consistent results, making padding mangles ideal for delicate or high-quality textiles.

Benefits of Foulard Mangle in Textile Processing

Foulard mangle offers superior fabric finish quality by enhancing dye fixation and color uniformity compared to padding mangle, which primarily focuses on applying chemicals. You benefit from improved fabric softness, reduced creasing, and better penetration of finishing agents with foulard mangles, making them ideal for delicate or high-end textiles. Their precise pressure control and adjustable speed optimize textile processing efficiency and result in consistent, high-quality fabric outcomes.

Applications of Padding Mangle in the Textile Industry

Padding mangles are essential in the textile industry for applying uniform chemical finishes, dyes, and water-repellent agents to fabrics with precision and efficiency. You will find padding mangles widely used in processes like bleaching, dyeing, and resin application where fabric needs to be saturated uniformly while maintaining fabric integrity. Their ability to handle large volumes continuously makes them ideal for achieving consistent quality in industrial-scale textile finishing.

Typical Uses of Foulard Mangle

Foulard mangle is typically used in textile industries for softening and finishing fine fabrics such as silk, wool, and cotton, enhancing their smoothness and luster. Its gentle pressing and smoothing action is ideal for delicate materials that require careful handling to preserve texture and appearance. You can rely on foulard mangle for upgrading fabric quality during garment production or textile manufacturing processes.

Choosing Between Padding Mangle and Foulard Mangle

Choosing between a padding mangle and a foulard mangle depends on the desired fabric finish and production requirements. Padding mangles are ideal for applying thick, even coatings of liquid finishes or dyes, ensuring deep penetration and uniformity on heavy textiles. Foulard mangles excel in producing smooth, polished fabric surfaces with precise pressure control, making them suitable for delicate or decorative textile treatments.

Conclusion: Which Mangle is Best for Your Textile Needs?

Padding mangles excel in applying consistent pressure for heavy fabrics and industrial textile processing, ensuring uniform thickness and moisture distribution. Foulard mangles specialize in delicate fabric finishing and patterning with precise roller control, ideal for fine textiles and detailed designs. Choosing the best mangle depends on fabric type and processing goals: padding mangles suit robust materials and moisture treatment, while foulard mangles cater to intricate finishing and gentle handling.

Padding mangle vs Foulard mangle Infographic

libmatt.com

libmatt.com