Mercerization enhances fabric strength, luster, and dye affinity by treating cotton with a strong alkali solution, improving its durability and appearance. Singeing removes surface fibers from fabric to create a smooth finish and reduce pilling, ensuring your textiles have a clean, polished look.

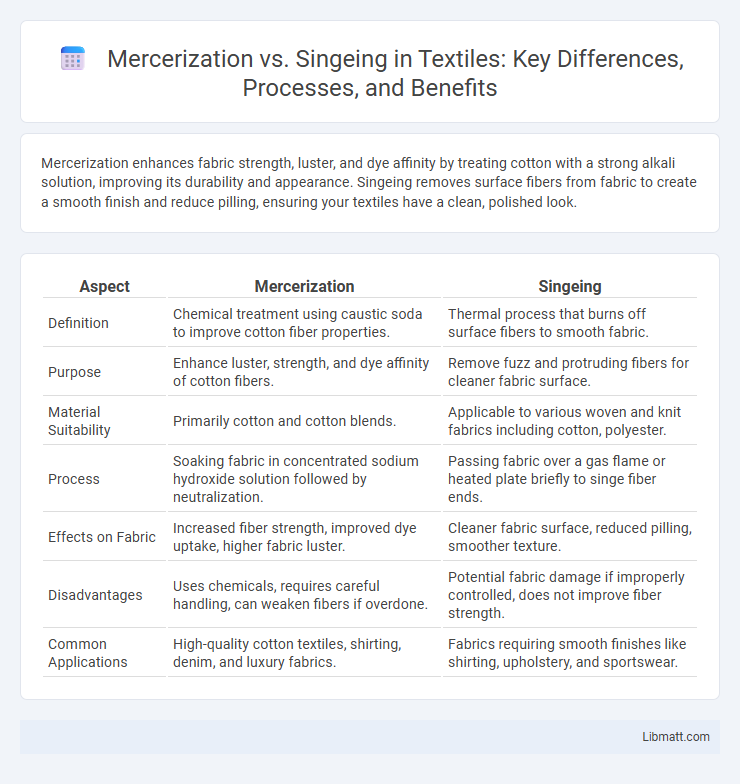

Table of Comparison

| Aspect | Mercerization | Singeing |

|---|---|---|

| Definition | Chemical treatment using caustic soda to improve cotton fiber properties. | Thermal process that burns off surface fibers to smooth fabric. |

| Purpose | Enhance luster, strength, and dye affinity of cotton fibers. | Remove fuzz and protruding fibers for cleaner fabric surface. |

| Material Suitability | Primarily cotton and cotton blends. | Applicable to various woven and knit fabrics including cotton, polyester. |

| Process | Soaking fabric in concentrated sodium hydroxide solution followed by neutralization. | Passing fabric over a gas flame or heated plate briefly to singe fiber ends. |

| Effects on Fabric | Increased fiber strength, improved dye uptake, higher fabric luster. | Cleaner fabric surface, reduced pilling, smoother texture. |

| Disadvantages | Uses chemicals, requires careful handling, can weaken fibers if overdone. | Potential fabric damage if improperly controlled, does not improve fiber strength. |

| Common Applications | High-quality cotton textiles, shirting, denim, and luxury fabrics. | Fabrics requiring smooth finishes like shirting, upholstery, and sportswear. |

Introduction to Mercerization and Singeing

Mercerization is a textile finishing process that involves treating cotton fibers with a strong caustic soda solution to improve luster, strength, and dye affinity. Singeing is a fabric treatment that removes surface fibers or fuzz by passing the fabric over a flame or heated copper plates, resulting in a smooth, clean appearance. Your fabric's quality and texture are significantly enhanced by choosing the appropriate process between Mercerization and Singeing.

Historical Background of Textile Finishing

Mercerization, developed in the mid-19th century by John Mercer, revolutionized cotton fabric finishing by enhancing strength, luster, and dye affinity through sodium hydroxide treatment. Singeing, with origins tracing back to ancient textile practices, involves burning off surface fibers to achieve a smooth, clean fabric finish, improving appearance and reducing pilling. Both techniques have historically advanced textile finishing by improving fabric quality, durability, and aesthetics, forming foundational processes in modern textile manufacturing.

What is Mercerization?

Mercerization is a textile finishing process applied to cotton fibers or fabrics to enhance luster, strength, and dye affinity by treating the material with a concentrated sodium hydroxide solution under tension. This chemical treatment alters the fiber's structure, resulting in improved absorbency and a smoother, silk-like appearance. Mercerized cotton exhibits richer color vibrancy and greater durability compared to untreated fibers, making it a preferred choice in high-quality textile production.

What is Singeing?

Singeing is a textile finishing process that involves passing fabric or yarn through a flame or heated copper plates to remove surface fibers and create a smooth, clean appearance. This method reduces pilling and enhances the fabric's texture by eliminating fuzz and protruding fibers. Singeing improves the quality and printability of materials, making it essential in producing polished, high-quality textiles.

Purposes and Benefits of Mercerization

Mercerization enhances the strength, luster, and dye affinity of cotton fibers by treating them with a concentrated caustic soda solution, resulting in smoother, more durable, and more vibrant fabrics. This chemical process reduces fabric shrinkage and improves resistance to mildew, making it essential for high-quality textile production. Unlike singeing, which only removes surface fibers for a cleaner appearance, mercerization fundamentally improves the structural properties of the fiber itself.

Purposes and Benefits of Singeing

Singeing is a textile finishing process that removes surface fibers and fuzz from fabric, enhancing its smoothness and improving the fabric's overall appearance. This treatment results in reduced pilling, improved dyeing uniformity, and greater fabric durability, which are essential for high-quality textile production. Unlike mercerization, which primarily strengthens and increases luster in cotton fibers, singeing focuses on surface refinement to achieve a cleaner, more polished fabric texture.

Key Differences Between Mercerization and Singeing

Mercerization enhances fabric strength, luster, and dye affinity by treating cotton with sodium hydroxide, while singeing removes surface fibers by passing the fabric over a flame or heated plates to achieve a smooth finish. Mercerization improves absorbency and fabric durability, whereas singeing primarily focuses on reducing pilling and fuzziness to improve fabric appearance. Your choice between these processes depends on whether you prioritize fabric strength and dye quality or surface smoothness and clean aesthetics.

Impact on Fabric Quality and Performance

Mercerization enhances fabric quality by increasing luster, strength, and dye affinity, resulting in more vibrant colors and improved durability. Singeing improves fabric performance by removing surface fibers, creating a smooth and clean finish that reduces pilling and enhances print clarity. Both processes significantly elevate the tactile feel and visual appeal of textiles, but Mercerization predominantly impacts fiber structure while Singeing targets surface refinement.

Environmental and Economic Considerations

Mercerization enhances fabric strength and dye affinity but involves high water and chemical usage, impacting environmental sustainability and increasing processing costs. Singeing improves fabric appearance by burning off surface fibers with minimal resource consumption, leading to lower environmental impact and operational expenses. Your choice between these treatments should balance fabric quality improvements against environmental footprint and economic feasibility.

Choosing the Right Finishing Process for Textiles

Selecting between mercerization and singeing depends on the desired fabric attributes and end-use requirements. Mercerization enhances cotton's strength, luster, and dye affinity through alkaline treatment, making it ideal for high-quality apparel and home textiles. Singeing, by removing surface fibers via controlled burning, improves fabric smoothness and prevents pilling, suitable for fine textiles needing a clean finish and enhanced durability.

Mercerization vs Singeing Infographic

libmatt.com

libmatt.com