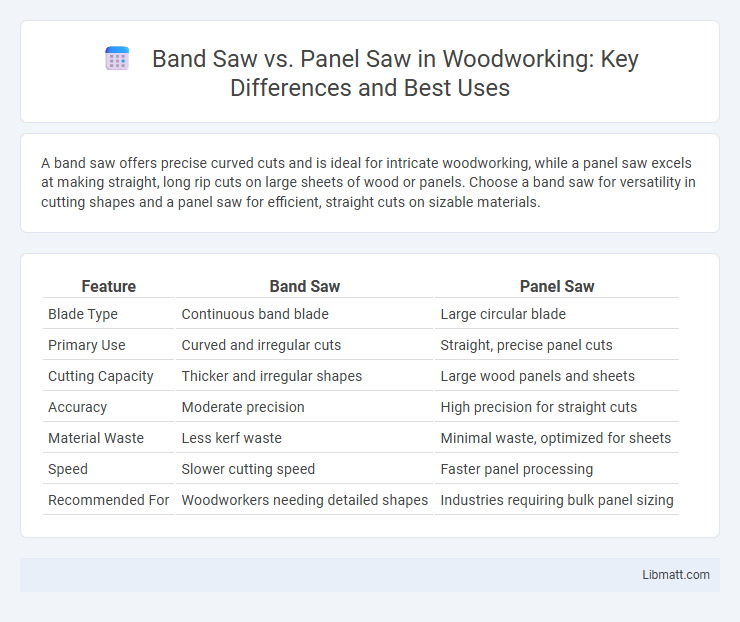

A band saw offers precise curved cuts and is ideal for intricate woodworking, while a panel saw excels at making straight, long rip cuts on large sheets of wood or panels. Choose a band saw for versatility in cutting shapes and a panel saw for efficient, straight cuts on sizable materials.

Table of Comparison

| Feature | Band Saw | Panel Saw |

|---|---|---|

| Blade Type | Continuous band blade | Large circular blade |

| Primary Use | Curved and irregular cuts | Straight, precise panel cuts |

| Cutting Capacity | Thicker and irregular shapes | Large wood panels and sheets |

| Accuracy | Moderate precision | High precision for straight cuts |

| Material Waste | Less kerf waste | Minimal waste, optimized for sheets |

| Speed | Slower cutting speed | Faster panel processing |

| Recommended For | Woodworkers needing detailed shapes | Industries requiring bulk panel sizing |

Introduction to Band Saw vs Panel Saw

A band saw uses a continuous flexible blade to make precise curved or straight cuts, ideal for detailed woodworking and metalworking tasks. A panel saw features a large vertical or horizontal frame designed for cutting large sheets of material like plywood or MDF with accuracy and speed. Choosing the right saw depends on your project's size, material type, and cut complexity.

Key Differences Between Band Saws and Panel Saws

Band saws use a continuous loop blade ideal for curved and irregular cuts, offering versatility in cutting thickness and shapes. Panel saws feature a large, vertically mounted blade designed for precise, straight cuts on large sheet materials like plywood or MDF. The main difference lies in their blade design and cutting capabilities, with band saws excelling in intricate curves and panel saws providing accuracy in straight, repeatable cuts.

Overview of Band Saws

Band saws feature a continuous loop blade that allows for precise curved and irregular cuts in wood, metal, and other materials. They excel in resawing, ripping thick lumber, and intricate cutting tasks that require smooth, consistent motion. The vertical or horizontal blade orientation provides versatility for detailed craftsmanship and heavy-duty industrial applications.

Overview of Panel Saws

Panel saws are specialized woodworking machines designed for cutting large sheets of material such as plywood, MDF, and particleboard with high precision and efficiency. They feature vertical or horizontal setups with adjustable guides and scoring blades to minimize splintering and ensure clean, straight cuts. Commonly used in cabinet making and furniture production, panel saws excel at handling large-format panels quickly while maintaining accuracy.

Cutting Capacity and Applications

Band saws offer higher cutting capacity for thick and irregular materials, making them ideal for detailed curve cuts and resawing tasks. Panel saws excel in cutting large sheet goods like plywood and MDF into precise straight lines, optimizing efficiency for panel processing in woodworking shops. Your choice depends on whether you prioritize versatility and thickness or speed and accuracy for large format cuts.

Material Versatility

Band saws excel in cutting a wide variety of materials, ranging from hardwood and softwood to metals and plastics, due to their thin, flexible blade that can navigate curves and irregular shapes with precision. Panel saws are optimized for straight cuts on large sheet materials like plywood, MDF, and particleboard, delivering high accuracy but limited in handling non-flat or irregularly shaped materials. The choice depends on whether material versatility with complex cuts or precision in large panel sizing is the priority.

Precision and Accuracy

A band saw offers high precision for curved and irregular cuts thanks to its narrow blade, making it ideal for detailed woodworking and metal cutting tasks. Panel saws excel in accuracy with straight cuts on large sheet materials, utilizing guide systems and rails to ensure consistent, square edges. Choosing between the two depends on the specific precision needs: intricate contours favor band saws, while panel saws provide superior accuracy for straight, large panel cuts.

Safety Considerations

Band saws require careful handling due to their exposed blade and potential kickback risk, necessitating the use of blade guards and push sticks to minimize injury. Panel saws, designed for cutting large sheets, often have enclosed blades and automatic safety features, reducing direct contact hazards. Both saw types demand proper training, personal protective equipment (PPE), and adherence to safety protocols to prevent accidents.

Maintenance and Durability

Band saws require regular blade tension adjustments and periodic replacement of worn blades to maintain cutting precision, while panel saws demand routine lubrication of moving parts and inspection of saw blades for sharpness and alignment. Durability in band saws is often enhanced by robust frame construction and quality blade guides that resist wear, whereas panel saws benefit from heavy-duty rails and stable sliding mechanisms that ensure long-term operational stability. Both saw types benefit from consistent cleaning and timely maintenance to prevent dust buildup and mechanical deterioration, extending their service life in woodworking environments.

Choosing the Right Saw for Your Workshop

Selecting the right saw for your workshop depends on the specific woodworking tasks and material dimensions you handle regularly. Band saws excel in cutting irregular shapes, curves, and resawing thick lumber with precision, making them ideal for detailed and versatile projects. Panel saws are designed for efficient, straight cuts on large panels and sheet materials, offering speed and accuracy crucial for cabinetry, furniture making, and large-scale woodworking jobs.

Band saw vs Panel saw Infographic

libmatt.com

libmatt.com