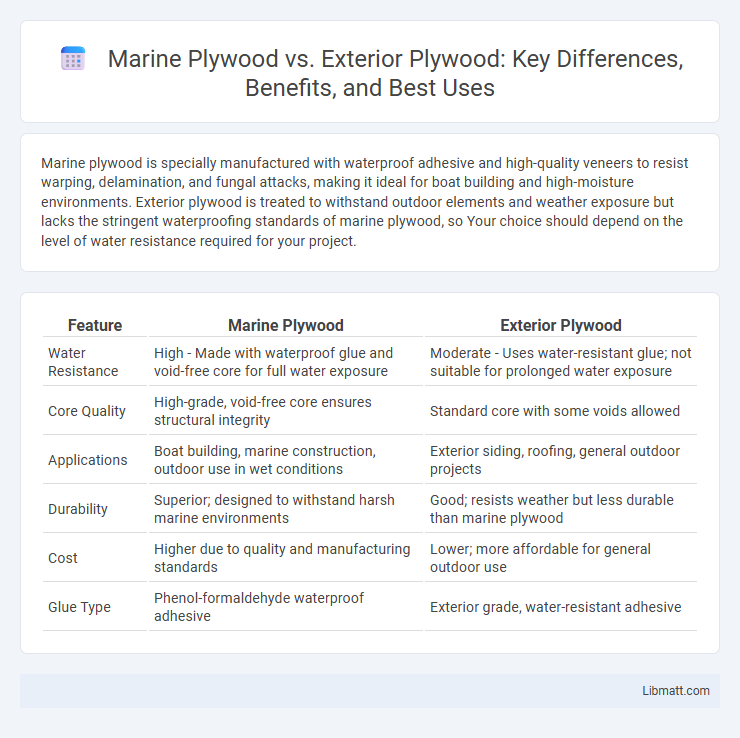

Marine plywood is specially manufactured with waterproof adhesive and high-quality veneers to resist warping, delamination, and fungal attacks, making it ideal for boat building and high-moisture environments. Exterior plywood is treated to withstand outdoor elements and weather exposure but lacks the stringent waterproofing standards of marine plywood, so Your choice should depend on the level of water resistance required for your project.

Table of Comparison

| Feature | Marine Plywood | Exterior Plywood |

|---|---|---|

| Water Resistance | High - Made with waterproof glue and void-free core for full water exposure | Moderate - Uses water-resistant glue; not suitable for prolonged water exposure |

| Core Quality | High-grade, void-free core ensures structural integrity | Standard core with some voids allowed |

| Applications | Boat building, marine construction, outdoor use in wet conditions | Exterior siding, roofing, general outdoor projects |

| Durability | Superior; designed to withstand harsh marine environments | Good; resists weather but less durable than marine plywood |

| Cost | Higher due to quality and manufacturing standards | Lower; more affordable for general outdoor use |

| Glue Type | Phenol-formaldehyde waterproof adhesive | Exterior grade, water-resistant adhesive |

Introduction to Marine Plywood vs Exterior Plywood

Marine plywood is engineered with high-quality hardwood veneers and waterproof adhesive to withstand prolonged exposure to moisture and harsh marine environments, making it ideal for boat construction and water-related applications. Exterior plywood is designed with weather-resistant adhesives and pressure-treated wood to endure outdoor conditions such as rain and humidity, commonly used for exterior walls, roofing, and outdoor furniture. Both plywood types offer durability and water resistance but differ in manufacturing standards and material quality tailored to specific environmental demands.

Key Differences Between Marine and Exterior Plywood

Marine plywood features waterproof glue and higher-quality veneers to resist delamination and fungal attacks, making it ideal for water-exposed environments. Exterior plywood uses water-resistant adhesives and is designed for outdoor applications but lacks the stringent standards of marine plywood for prolonged wet conditions. The core and face veneers in marine plywood undergo superior grading and treatment, ensuring durability against moisture compared to standard exterior plywood.

Manufacturing Standards and Certifications

Marine plywood is manufactured using high-quality hardwood veneers and waterproof adhesives that meet stringent standards such as BS 1088, ensuring durability and resistance to moisture, fungi, and rot. Exterior plywood, while also constructed with weather-resistant glue, adheres to less rigorous standards like APA Class 1 or 2, making it suitable for outdoor use but less durable in continuous water exposure. Your choice depends on the required level of moisture resistance and certification compliance for long-term performance in marine or exterior applications.

Material Composition and Glue Types

Marine plywood is crafted from durable hardwood veneers with void-free cores, bonded using waterproof phenolic resin glue designed to withstand prolonged water exposure without delamination. Exterior plywood typically uses softwood veneers and is glued with water-resistant adhesives such as melamine-urea-formaldehyde resin, which offers protection against moisture but is less durable in constant wet conditions. The advanced glue types and higher-grade veneer quality in marine plywood make it ideal for heavy marine and outdoor applications where water resistance is critical.

Water Resistance and Durability

Marine plywood features high-quality veneers bonded with waterproof adhesive, making it highly water-resistant and suitable for prolonged exposure to moisture without delaminating. Exterior plywood is designed with phenolic glue to withstand occasional wet conditions but lacks the rigorous bonding and defect-free veneers of marine-grade plywood, resulting in lower durability in constantly wet environments. The densest, void-free core of marine plywood enhances its structural integrity and resistance to fungal attack, while exterior plywood may swell or deteriorate under continuous water exposure.

Common Applications of Marine Plywood

Marine plywood is primarily used in boat building, docks, and other aquatic structures due to its superior water resistance and durability. Its high-quality veneers and waterproof adhesive make it ideal for applications where prolonged exposure to moisture is expected. Your projects involving outdoor furniture, ship interiors, or wet environments benefit greatly from marine plywood's robust construction and resistance to fungal attacks.

Common Applications of Exterior Plywood

Exterior plywood is widely used in construction projects that require weather-resistant and durable materials, such as roofing, siding, and wall sheathing. Its ability to withstand moisture and varying temperatures makes it ideal for outdoor structures like decks, fences, and garden sheds. This plywood type often features waterproof adhesives and enhanced treatments to improve resistance against decay and fungal attack.

Cost Comparison of Marine and Exterior Plywood

Marine plywood generally costs significantly more than exterior plywood due to its higher-grade adhesives and superior resistance to moisture and fungal decay. Exterior plywood is budget-friendly and suitable for outdoor applications where occasional exposure to moisture occurs but lacks the durability and water resistance of marine plywood. The price difference reflects the intended use, with marine plywood preferred for demanding, long-term water exposure projects and exterior plywood for less critical, cost-sensitive outdoor tasks.

Pros and Cons of Marine Plywood vs Exterior Plywood

Marine plywood offers superior water resistance and durability due to its high-quality adhesives and fewer voids, making it ideal for boat building and outdoor projects exposed to heavy moisture. Exterior plywood is more affordable and suitable for outdoor use but may delaminate or degrade over time when exposed to constant water or extreme weather conditions. Your choice depends on the project's exposure to water and budget constraints, with marine plywood providing long-term reliability and exterior plywood offering cost-effective versatility.

How to Choose the Right Plywood for Your Project

Marine plywood offers superior water resistance due to its waterproof adhesive and high-quality hardwood veneers, making it ideal for boat building, outdoor furniture, and projects exposed to moisture. Exterior plywood is designed with water-resistant glue and treated veneers suitable for general outdoor use such as siding and roofing but lacks the same structural integrity and mold resistance as marine plywood. Choosing the right plywood depends on the specific exposure to water, required strength, and durability; marine plywood suits heavy moisture environments, while exterior plywood is sufficient for less demanding outdoor applications.

Marine plywood vs Exterior plywood Infographic

libmatt.com

libmatt.com