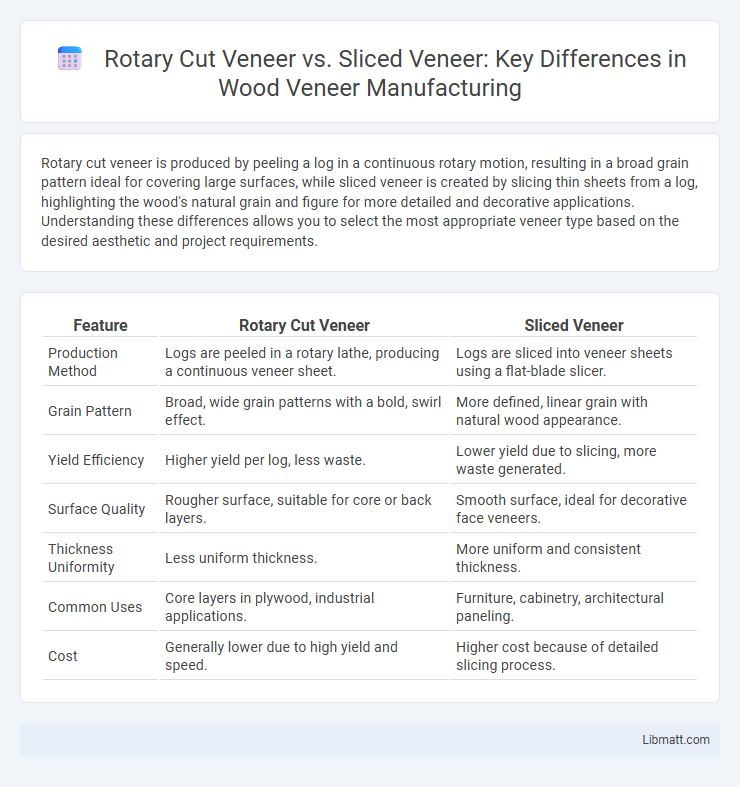

Rotary cut veneer is produced by peeling a log in a continuous rotary motion, resulting in a broad grain pattern ideal for covering large surfaces, while sliced veneer is created by slicing thin sheets from a log, highlighting the wood's natural grain and figure for more detailed and decorative applications. Understanding these differences allows you to select the most appropriate veneer type based on the desired aesthetic and project requirements.

Table of Comparison

| Feature | Rotary Cut Veneer | Sliced Veneer |

|---|---|---|

| Production Method | Logs are peeled in a rotary lathe, producing a continuous veneer sheet. | Logs are sliced into veneer sheets using a flat-blade slicer. |

| Grain Pattern | Broad, wide grain patterns with a bold, swirl effect. | More defined, linear grain with natural wood appearance. |

| Yield Efficiency | Higher yield per log, less waste. | Lower yield due to slicing, more waste generated. |

| Surface Quality | Rougher surface, suitable for core or back layers. | Smooth surface, ideal for decorative face veneers. |

| Thickness Uniformity | Less uniform thickness. | More uniform and consistent thickness. |

| Common Uses | Core layers in plywood, industrial applications. | Furniture, cabinetry, architectural paneling. |

| Cost | Generally lower due to high yield and speed. | Higher cost because of detailed slicing process. |

Introduction to Veneer Types

Rotary cut veneer is produced by peeling a log in a continuous, circular motion, creating wide sheets with a distinctive grain pattern ideal for plywood and inexpensive surfaces. Sliced veneer is made by cutting the log into thin sheets, preserving the natural grain and texture, offering a more refined and decorative appearance often used in high-quality furniture. Both veneer types provide cost-effective wood coverings but differ significantly in grain aesthetics and manufacturing processes.

Understanding Rotary Cut Veneer

Rotary cut veneer is produced by peeling a log in a continuous rotary fashion, resulting in a broad, consistent grain pattern often used for plywood and laminates. This method maximizes wood yield, making it cost-effective compared to sliced veneer, which is cut into thinner sheets with more varied grain textures. Rotary cut veneer typically has a bolder, less detailed appearance, ideal for applications where uniformity is prioritized over ornamental grain patterns.

What is Sliced Veneer?

Sliced veneer is a type of wood veneer produced by cutting a log into thin sheets using a large blade, resulting in a flat, consistent grain pattern that highlights the natural texture of the wood. Unlike rotary cut veneer, which involves peeling the log in a continuous spiral, sliced veneer offers more precise and uniform grain alignment, making it ideal for fine furniture and cabinetry. Its smooth surface and distinct grain patterns provide a refined aesthetic commonly used in high-quality wood applications.

Manufacturing Processes Compared

Rotary cut veneer is produced by rotating a log against a blade, peeling off continuous sheets of wood, which results in broad grain patterns and higher yield from each log. Sliced veneer is made by slicing thin sheets from a log or flitch, perpendicular to the growth rings, capturing natural grain details and texture. The rotary cut method maximizes material efficiency, whereas slicing emphasizes aesthetic quality with more intricate grain patterns.

Grain Patterns and Visual Differences

Rotary cut veneer features broad, swirling grain patterns created by peeling the log in a continuous spiral, resulting in a more rustic and variable appearance ideal for covering large surfaces. Sliced veneer, produced by cutting thin sheets perpendicular to the log's growth rings, reveals straighter, more consistent grain patterns that highlight the natural wood figure with greater detail and elegance. The visual difference lies in rotary veneer's dynamic, bold patterns compared to the refined, linear aesthetics characteristic of sliced veneer.

Applications and Best Uses

Rotary cut veneer is ideal for large surfaces requiring continuous grain patterns, making it perfect for plywood, furniture panels, and architectural millwork where cost-efficiency and coverage are priorities. Sliced veneer offers more refined, varied grain patterns suited for high-end cabinetry, decorative wall panels, and custom furniture, enhancing aesthetic appeal with unique textures. Your choice depends on whether you prioritize expansive uniformity with rotary cut or the artistic detail and elegance of sliced veneer.

Cost Comparison: Rotary vs Sliced

Rotary cut veneer typically costs less than sliced veneer due to its production efficiency and higher yield from logs, making it ideal for large-scale projects requiring economical material. Sliced veneer, produced by carefully slicing logs to reveal distinctive grain patterns, involves more labor and waste, resulting in higher costs and premium pricing. The choice between rotary and sliced veneer balances budget constraints with desired aesthetic quality and grain detail.

Durability and Performance

Rotary cut veneer offers high durability due to its continuous grain pattern, making it resistant to warping and ideal for large surface areas requiring consistent performance. Sliced veneer exhibits more intricate grain patterns but may be less stable under heavy stress, affecting long-term durability in high-wear applications. For projects demanding maximum resilience and uniform strength, choosing the appropriate veneer type ensures Your surfaces maintain structural integrity and aesthetic appeal over time.

Environmental Impact and Sustainability

Rotary cut veneer produces less waste compared to sliced veneer because the log is peeled in a continuous sheet, maximizing the wood utilization rate and reducing the number of unusable scraps. Sliced veneer, while offering higher aesthetic quality, results in more wood waste and energy consumption due to intricate cutting and handling processes. Choosing rotary cut veneer supports sustainable forestry practices by optimizing log usage, minimizing resource depletion, and lowering overall environmental impact in wood product manufacturing.

How to Choose the Right Veneer

Rotary cut veneer offers a broad, bold grain pattern ideal for covering large surfaces like plywood or particleboard, while sliced veneer provides more refined, consistent patterns suited for furniture and cabinetry where aesthetics are paramount. Your choice should consider the desired visual effect, application surface, and budget, as rotary veneer is generally more cost-effective but less detailed than sliced veneer. Selecting the right veneer depends on balancing durability, grain appearance, and the specific design requirements of your project.

Rotary cut veneer vs Sliced veneer Infographic

libmatt.com

libmatt.com