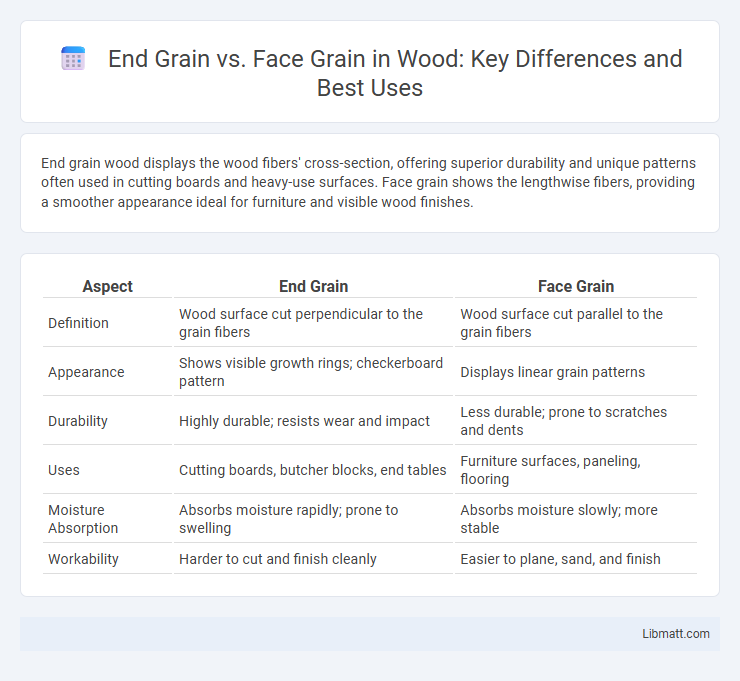

End grain wood displays the wood fibers' cross-section, offering superior durability and unique patterns often used in cutting boards and heavy-use surfaces. Face grain shows the lengthwise fibers, providing a smoother appearance ideal for furniture and visible wood finishes.

Table of Comparison

| Aspect | End Grain | Face Grain |

|---|---|---|

| Definition | Wood surface cut perpendicular to the grain fibers | Wood surface cut parallel to the grain fibers |

| Appearance | Shows visible growth rings; checkerboard pattern | Displays linear grain patterns |

| Durability | Highly durable; resists wear and impact | Less durable; prone to scratches and dents |

| Uses | Cutting boards, butcher blocks, end tables | Furniture surfaces, paneling, flooring |

| Moisture Absorption | Absorbs moisture rapidly; prone to swelling | Absorbs moisture slowly; more stable |

| Workability | Harder to cut and finish cleanly | Easier to plane, sand, and finish |

Understanding Wood Grain: End Grain vs Face Grain

End grain refers to the cross-section of wood fibers visible when a board is cut perpendicular to the growth rings, showcasing a pattern of tightly packed cells that absorb finishes differently and exhibit superior durability and moisture resistance. Face grain, or flat grain, runs parallel to the growth rings, highlighting the wood's natural texture and color variations, making it ideal for aesthetic surfaces such as tabletops and cabinetry. Understanding the structural differences between end grain and face grain is crucial for woodworking applications, as it influences cutting, finishing techniques, and the overall performance of the wood in various environments.

Key Differences Between End Grain and Face Grain

End grain exhibits wood fibers oriented vertically, resulting in greater durability and resistance to knife marks, making it ideal for cutting boards designed for longevity. Face grain, with fibers running horizontally along the wood's surface, offers a smoother texture and more visible grain patterns, enhancing aesthetic appeal but making it more prone to scratches. Understanding these key differences helps you choose the right wood grain for your specific woodworking projects or kitchen tools.

Visual Characteristics of End Grain and Face Grain

End grain displays a unique checkerboard pattern with exposed wood fibers, often revealing intricate growth rings and a textured surface that enhances the wood's natural beauty. Face grain showcases long, continuous grain lines running parallel to the board's length, offering a smooth appearance with visible annual rings and color variations. The contrast between end grain's detailed, mosaic-like look and face grain's linear patterns significantly influences wood selection in furniture design and cutting boards.

Durability and Performance Comparison

End grain wood exhibits superior durability and performance due to its ability to absorb impacts and resist knife marks, making it ideal for cutting boards and heavy-use surfaces. Face grain wood, while visually appealing and easier to work with, tends to show wear and scratches more quickly because the grain runs along the surface rather than perpendicular. Understanding the differences helps you choose the right wood grain for applications demanding long-lasting performance.

Applications: When to Use End Grain vs Face Grain

End grain surfaces excel in applications requiring superior knife edge retention and durability, such as cutting boards and butcher blocks, because the wood fibers absorb impact and reduce blade dulling. Face grain is preferred for furniture, cabinetry, and visible wood panels where a smooth, aesthetically pleasing surface and clear wood grain patterns are desired. Choosing between end grain and face grain depends on balancing functionality--impact resistance and durability for end grain--with visual appeal and structural stability for face grain projects.

Cutting Boards: End Grain or Face Grain?

End grain cutting boards, made by aligning wood fibers vertically, provide superior durability and self-healing properties, reducing knife marks and preserving blade sharpness. Face grain boards showcase wood's natural patterns and are often more affordable but tend to wear faster and show scratches more prominently. Choosing end grain boards enhances longevity and cutting performance, making them ideal for heavy kitchen use.

Maintenance and Care for Both Grain Types

End grain wood requires more frequent oiling and careful drying to prevent cracking and warping due to its porous structure. Face grain surfaces are generally easier to clean and maintain but are more prone to visible scratches and dents, so gentle cleaning and prompt repair are essential. Your choice between end grain and face grain will influence the specific maintenance routine to preserve durability and appearance.

Cost Differences and Material Efficiency

End grain wood tends to be more expensive than face grain due to the increased labor and precision required to cut and finish it, as well as the higher waste generated during production. Face grain offers greater material efficiency because it utilizes larger, continuous sections of wood, resulting in less waste and lower overall costs. Your choice between end grain and face grain will significantly impact project budget and material utilization based on these cost and efficiency differences.

Pros and Cons of End Grain and Face Grain

End grain cutting boards offer superior knife edge retention and greater durability due to the wood fibers absorbing impact, but they can be more expensive and require frequent oiling to prevent cracking. Face grain boards are typically more affordable and visually appealing with prominent wood patterns but are less resistant to cuts and can show knife marks more quickly. Choosing between end grain and face grain depends on whether durability and knife preservation or cost and aesthetics are prioritized.

Choosing the Right Grain for Your Woodworking Project

Selecting between end grain and face grain significantly impacts the durability and appearance of woodworking projects. End grain, characterized by wood fibers' exposed cross-section, offers superior resistance to wear and is ideal for cutting boards and butcher blocks. Face grain, showcasing the wood's lengthwise fiber pattern, provides greater stability and a smoother surface, making it perfect for furniture and paneling.

End grain vs face grain Infographic

libmatt.com

libmatt.com