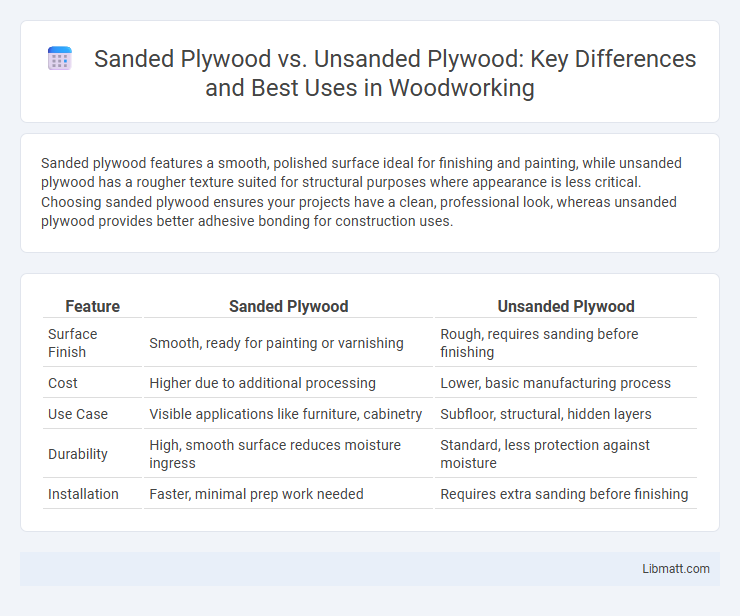

Sanded plywood features a smooth, polished surface ideal for finishing and painting, while unsanded plywood has a rougher texture suited for structural purposes where appearance is less critical. Choosing sanded plywood ensures your projects have a clean, professional look, whereas unsanded plywood provides better adhesive bonding for construction uses.

Table of Comparison

| Feature | Sanded Plywood | Unsanded Plywood |

|---|---|---|

| Surface Finish | Smooth, ready for painting or varnishing | Rough, requires sanding before finishing |

| Cost | Higher due to additional processing | Lower, basic manufacturing process |

| Use Case | Visible applications like furniture, cabinetry | Subfloor, structural, hidden layers |

| Durability | High, smooth surface reduces moisture ingress | Standard, less protection against moisture |

| Installation | Faster, minimal prep work needed | Requires extra sanding before finishing |

Introduction to Plywood Types

Sanded plywood features a smooth surface achieved through fine sanding, making it ideal for visible indoor applications like cabinetry and furniture where finish quality matters. Unsanded plywood retains a rough texture with minimal surface treatment, commonly used in construction and structural projects where appearance is less critical but strength and durability are essential. Both types consist of multiple veneer layers glued together, but their suitability varies depending on the finishing requirements and intended use.

What is Sanded Plywood?

Sanded plywood features a smooth, uniform surface achieved through a mechanical sanding process that removes imperfections and roughness, making it ideal for visible applications like furniture and cabinetry. This type of plywood offers better paint adhesion, a polished finish, and easier customization compared to unsanded plywood, which typically has a rough texture and is used in structural or hidden applications. Choosing sanded plywood can enhance the aesthetic quality and durability of your woodworking projects.

What is Unsanded Plywood?

Unsanded plywood is a type of plywood that has not undergone the sanding process, resulting in a rougher surface texture compared to sanded plywood. This untreated surface makes it ideal for construction projects where the plywood will be covered or hidden, such as subflooring or structural sheathing. You may choose unsanded plywood when appearance is less critical and a strong, cost-effective material is required.

Surface Quality Comparison

Sanded plywood features a smooth, refined surface achieved through mechanical sanding, making it ideal for visible applications like cabinetry and furniture where finish quality is paramount. Unsanded plywood retains a rougher texture, suitable for structural or less visually critical uses, providing better adhesion for glues and paints due to its coarse surface. Choosing between sanded and unsanded plywood depends on the desired finish quality and the intended use, with sanded plywood offering superior surface smoothness for detailed painting or varnishing.

Strength and Durability Differences

Sanded plywood features a smooth surface due to its finely sanded veneer, enhancing its durability by reducing splinters and improving wear resistance, making it ideal for visible applications and finished furniture. Unsanded plywood retains a rougher texture, which can compromise surface strength but often provides better adhesion for glues or finishes, suitable for structural use where appearance is less critical. Strength-wise, both types maintain similar core plywood integrity, but sanded plywood offers superior surface robustness against daily wear and environmental factors.

Common Uses for Sanded Plywood

Sanded plywood is commonly used in applications requiring a smooth, finished surface, such as furniture making, cabinetry, and interior wall paneling. Its finely sanded surface improves paint and stain adhesion, making it ideal for decorative projects and visible indoor surfaces. This type of plywood also enhances lamination and veneer application, ensuring high-quality aesthetics in residential and commercial construction.

Applications of Unsanded Plywood

Unsanded plywood is ideal for applications where surface finishing is not crucial, such as structural support, subflooring, and sheathing in construction projects. Its rough texture provides better adhesion for adhesives and coatings in industrial uses, making it suitable for use in concrete formwork and packaging. Your choice of unsanded plywood can enhance the strength and durability of frameworks where smooth surfaces are unnecessary.

Cost Comparison: Sanded vs Unsanded

Sanded plywood typically costs more than unsanded plywood due to the extra labor and processing involved in smoothing the surface for a finer finish. Unsanded plywood offers a more budget-friendly option, ideal for structural applications where appearance is less critical. Choosing between the two depends on your project's requirements for surface quality versus cost efficiency.

Choosing the Right Plywood for Your Project

Choosing the right plywood for your project depends on the finish and application requirements. Sanded plywood offers a smooth, polished surface ideal for visible areas where aesthetics matter, while unsanded plywood is rougher and better suited for structural or concealed uses. Your decision should consider factors such as surface quality, durability, and the need for additional finishing.

Final Thoughts: Sanded vs Unsanded Plywood

Sanded plywood offers a smooth, uniform surface ideal for painting, staining, or finishing, enhancing aesthetic appeal and ease of application in cabinetry and furniture making. Unsanded plywood retains a rougher texture, often favored in structural or subflooring uses where surface finish is less critical but strength and cost-efficiency matter. Choosing between sanded and unsanded plywood depends on project requirements, balancing surface quality with budget and functional needs.

Sanded plywood vs Unsanded plywood Infographic

libmatt.com

libmatt.com