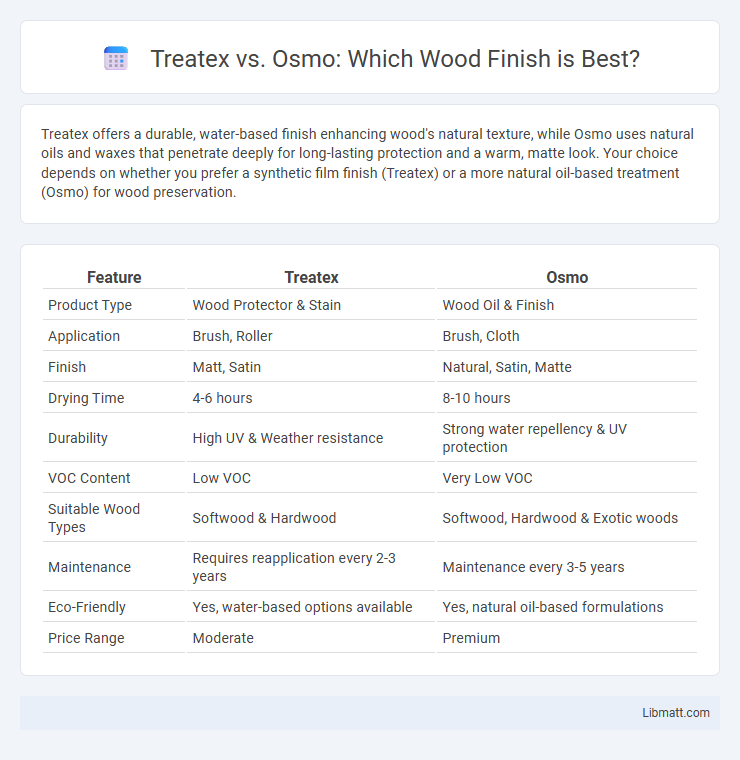

Treatex offers a durable, water-based finish enhancing wood's natural texture, while Osmo uses natural oils and waxes that penetrate deeply for long-lasting protection and a warm, matte look. Your choice depends on whether you prefer a synthetic film finish (Treatex) or a more natural oil-based treatment (Osmo) for wood preservation.

Table of Comparison

| Feature | Treatex | Osmo |

|---|---|---|

| Product Type | Wood Protector & Stain | Wood Oil & Finish |

| Application | Brush, Roller | Brush, Cloth |

| Finish | Matt, Satin | Natural, Satin, Matte |

| Drying Time | 4-6 hours | 8-10 hours |

| Durability | High UV & Weather resistance | Strong water repellency & UV protection |

| VOC Content | Low VOC | Very Low VOC |

| Suitable Wood Types | Softwood & Hardwood | Softwood, Hardwood & Exotic woods |

| Maintenance | Requires reapplication every 2-3 years | Maintenance every 3-5 years |

| Eco-Friendly | Yes, water-based options available | Yes, natural oil-based formulations |

| Price Range | Moderate | Premium |

Introduction to Treatex and Osmo

Treatex and Osmo are leading brands specializing in wood treatment products designed to protect and enhance wooden surfaces. Treatex offers a range of eco-friendly wood oils, stains, and finishes known for deep penetration and durability, making it ideal for both interior and exterior wood care. Osmo provides innovative wood coatings with natural plant-based oils and waxes, praised for superior weather resistance and maintaining wood's natural appearance over time.

Key Features Comparison

Treatex offers superior stain resistance and a rapid drying formula suitable for high-traffic wood surfaces, whereas Osmo excels in natural oil-based protection providing long-lasting UV resistance and moisture control. Both treatments enhance wood durability, but Treatex's synthetic composition delivers quicker recoat times, while Osmo's eco-friendly ingredients promote breathability and color retention. Choosing between Treatex and Osmo depends on the preference for fast application versus environmentally sustainable wood preservation.

Application Process Overview

Treatex offers a straightforward application process involving surface preparation, even brushing, and a drying time of 4-6 hours, ideal for wooden floors. Osmo requires careful cleaning and sanding of the surface, followed by applying thin layers with a brush or roller, allowing 8-12 hours between coats for optimal absorption. Your choice depends on the desired finish and drying time, with Treatex providing quicker usability and Osmo delivering durable protection with longer curing.

Durability and Protection

Treatex offers superior durability through its advanced oil and wax blend that penetrates deep into wood fibers, providing long-lasting protection against scratches and wear. Osmo is renowned for its natural, UV-resistant formula that enhances wood's resilience while maintaining breathability, reducing the risk of cracking or peeling over time. Both Treatex and Osmo deliver robust protection, but Treatex excels in surface hardness, whereas Osmo focuses on preserving wood's natural flexibility and moisture balance.

Finish and Appearance

Treatex offers a durable, matte finish that enhances the natural grain of wood while providing excellent protection against moisture and wear, making it ideal for high-traffic areas. Osmo features a distinct, oil-based finish that penetrates deeply into the wood, creating a rich, warm appearance with a natural, silky sheen that highlights the wood's texture. Your choice between Treatex and Osmo will depend on whether you prefer a subtle, protective matte look or a vibrant, nourishing finish that accentuates wood character.

Environmental Impact

Treatex uses natural oils and waxes that are biodegradable and sourced from renewable materials, resulting in a lower environmental impact compared to Osmo, which incorporates some synthetic additives. You benefit from Treatex's commitment to sustainability, as its formulations emit fewer volatile organic compounds (VOCs) and minimize ecological harm. Choosing Treatex supports eco-friendly woodworking practices while maintaining durable, high-quality finishes.

Maintenance Requirements

Treatex requires periodic reapplication and regular cleaning to maintain its protective finish, ensuring longevity and resistance to wear. Osmo offers a more durable surface with less frequent maintenance, as its oils and waxes penetrate deeply to protect wood naturally. Choosing Osmo can reduce your maintenance efforts while preserving the wood's natural appearance over time.

Cost Comparison

Treatex offers cost-effective wood finishing solutions with prices typically lower than Osmo's premium range, making it a budget-friendly option for large projects. Osmo products, while more expensive, provide longer-lasting finishes and require fewer applications, potentially reducing overall maintenance costs. Evaluating the total expenditure, including durability and application frequency, is crucial to determine the most economical choice between Treatex and Osmo.

User Reviews and Feedback

User reviews of Treatex highlight its strong water-resistant properties and smooth finish, making it a favorite for wooden surface protection. Osmo receives high marks for its natural oil-based formula that enhances wood grain and provides long-lasting durability. Your choice between Treatex and Osmo may depend on preferences for either quick drying time or eco-friendly ingredients noted in customer feedback.

Final Verdict: Treatex vs Osmo

Treatex offers superior durability and moisture resistance, making it ideal for high-traffic wooden surfaces, while Osmo excels in ease of application and natural wood enhancement. Your choice depends on whether you prioritize long-lasting protection or a more natural finish with simpler upkeep. For professional-grade performance and robustness, Treatex emerges as the final verdict, whereas Osmo suits DIY projects and aesthetic appeal better.

Treatex vs Osmo Infographic

libmatt.com

libmatt.com