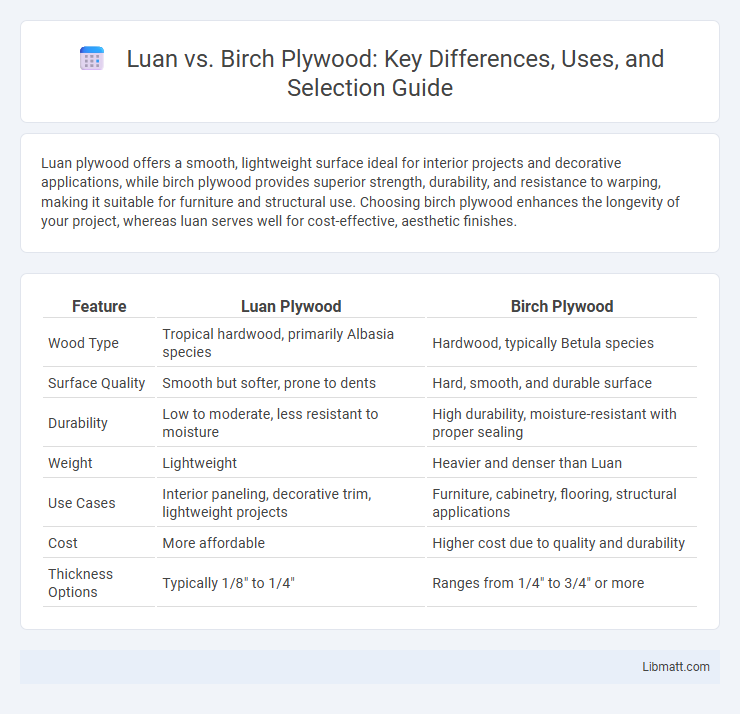

Luan plywood offers a smooth, lightweight surface ideal for interior projects and decorative applications, while birch plywood provides superior strength, durability, and resistance to warping, making it suitable for furniture and structural use. Choosing birch plywood enhances the longevity of your project, whereas luan serves well for cost-effective, aesthetic finishes.

Table of Comparison

| Feature | Luan Plywood | Birch Plywood |

|---|---|---|

| Wood Type | Tropical hardwood, primarily Albasia species | Hardwood, typically Betula species |

| Surface Quality | Smooth but softer, prone to dents | Hard, smooth, and durable surface |

| Durability | Low to moderate, less resistant to moisture | High durability, moisture-resistant with proper sealing |

| Weight | Lightweight | Heavier and denser than Luan |

| Use Cases | Interior paneling, decorative trim, lightweight projects | Furniture, cabinetry, flooring, structural applications |

| Cost | More affordable | Higher cost due to quality and durability |

| Thickness Options | Typically 1/8" to 1/4" | Ranges from 1/4" to 3/4" or more |

Luan vs Birch Plywood: An Overview

Luan plywood is a lightweight, affordable option commonly used for decorative purposes, offering good flexibility but less durability compared to birch plywood. Birch plywood, known for its strength and smooth finish, excels in structural applications and cabinetry due to its higher density and resistance to warping. Choosing between Luan and birch plywood depends on your project requirements for durability, appearance, and budget.

Material Composition: Luan Compared to Birch Plywood

Luan plywood is made from thin tropical hardwood veneers, primarily from Dipterocarpaceae species, resulting in a lightweight and flexible panel ideal for interior applications and decorative uses. Birch plywood consists of multiple layers of birch veneer, known for its exceptional strength, stability, and smooth surface, making it suitable for structural uses and furniture manufacturing. The higher density and uniform grain of birch plywood provide better durability and resistance to warping compared to the softer, more porous composition of Luan plywood.

Strength and Durability Differences

Birch plywood offers superior strength and durability compared to luan due to its hardwood composition and multiple dense layers, making it ideal for heavy-duty applications and structural use. Luan plywood, typically made from softer tropical wood, is thinner and less resilient, suitable primarily for lightweight projects like decorative paneling. The higher shear strength and impact resistance of birch plywood contribute to its longer lifespan under stress and exposure.

Surface Finish and Appearance

Luan plywood features a smooth, even surface with a fine grain ideal for painting and veneer applications, offering a consistent, clean look. Birch plywood boasts a naturally attractive, light-colored finish with tight grain patterns that enhance its aesthetic appeal, making it suitable for cabinetry and furniture with a premium appearance. Your choice depends on whether you prioritize a uniform base for finishing or a visually appealing natural wood surface.

Cost Comparison: Luan vs Birch Plywood

Luan plywood is generally more affordable, making it a cost-effective choice for budget-conscious projects, while birch plywood typically commands a higher price due to its superior strength and durability. The cost difference is influenced by factors such as wood quality, thickness, and applications, with birch often used in high-end furniture and cabinetry. Luan's lower cost suits lightweight, decorative purposes, whereas birch plywood's investment offers enhanced longevity and structural integrity.

Workability: Cutting, Nailing, and Finishing

Luan plywood offers superior workability with its smooth, fine-grain surface, making cutting, nailing, and finishing easier and producing cleaner edges compared to birch plywood. Birch plywood is denser and harder, requiring sharper tools and more precision for cutting and nailing, but it provides a more durable surface ideal for heavy-duty projects. For your woodworking tasks, Luan plywood is preferable when ease of handling and a smooth finish are priorities.

Common Applications for Luan and Birch Plywood

Luan plywood is commonly used for interior applications such as underlayment, paneling, and lightweight furniture due to its smooth surface and affordability. Birch plywood is favored for cabinetry, furniture making, and high-end millwork, offering superior strength and durability. Both materials provide versatility, but birch plywood's fine grain and stability make it ideal for visible, structural projects.

Environmental Impact and Sustainability

Birch plywood typically has a greater environmental impact than luan due to its slower growth rate and often intensive harvesting practices, which can contribute to deforestation if not sourced responsibly. Luan plywood, derived from tropical hardwoods, faces sustainability challenges linked to deforestation in Southeast Asian rainforests unless certified by organizations like the Forest Stewardship Council (FSC). To minimize environmental harm, you should select plywood products that guarantee sustainable practices and responsible forest management.

Availability and Sizing Options

Luan plywood is widely available in standard 4x8-foot sheets, commonly offered in thinner thicknesses ranging from 1/8 inch to 1/4 inch, making it ideal for lightweight interior applications. Birch plywood is also broadly accessible but provides a broader range of thickness options from 1/8 inch up to 1 inch or more, catering to structural and heavy-duty uses. Both materials are stocked in standard sheet sizes, though birch plywood's availability in thicker panels offers greater versatility for diverse construction and furniture projects.

Choosing the Right Plywood: Luan or Birch?

Luan plywood features a smooth surface and lightweight core, making it ideal for decorative projects and interior applications where flexibility and cost-efficiency are priorities. Birch plywood offers superior strength, durability, and a fine grain texture suited for structural uses, cabinetry, and furniture manufacturing demanding high-quality finish and load-bearing capacity. When choosing the right plywood, prioritize birch plywood for robust, long-lasting projects and luan plywood for economical decorative paneling and lightweight construction.

Luan vs birch plywood Infographic

libmatt.com

libmatt.com