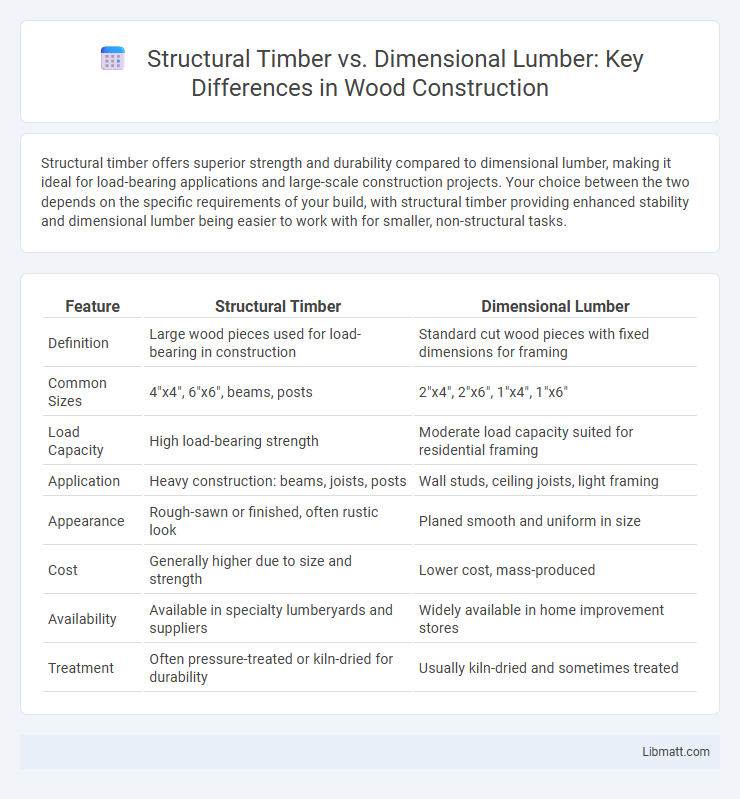

Structural timber offers superior strength and durability compared to dimensional lumber, making it ideal for load-bearing applications and large-scale construction projects. Your choice between the two depends on the specific requirements of your build, with structural timber providing enhanced stability and dimensional lumber being easier to work with for smaller, non-structural tasks.

Table of Comparison

| Feature | Structural Timber | Dimensional Lumber |

|---|---|---|

| Definition | Large wood pieces used for load-bearing in construction | Standard cut wood pieces with fixed dimensions for framing |

| Common Sizes | 4"x4", 6"x6", beams, posts | 2"x4", 2"x6", 1"x4", 1"x6" |

| Load Capacity | High load-bearing strength | Moderate load capacity suited for residential framing |

| Application | Heavy construction: beams, joists, posts | Wall studs, ceiling joists, light framing |

| Appearance | Rough-sawn or finished, often rustic look | Planed smooth and uniform in size |

| Cost | Generally higher due to size and strength | Lower cost, mass-produced |

| Availability | Available in specialty lumberyards and suppliers | Widely available in home improvement stores |

| Treatment | Often pressure-treated or kiln-dried for durability | Usually kiln-dried and sometimes treated |

Introduction to Structural Timber and Dimensional Lumber

Structural timber consists of large, solid wood pieces used primarily in heavy construction projects for load-bearing purposes, offering superior strength and durability compared to dimensional lumber. Dimensional lumber refers to wood that is sawn to standardized widths and depths, commonly used in residential framing and smaller-scale construction due to its uniformity and ease of use. Both materials play critical roles in building design, but structural timber is preferred for primary structural elements, while dimensional lumber is often utilized in non-critical framing and finishing tasks.

Definitions and Key Differences

Structural timber refers to large, often solid wood components used in heavy construction, providing substantial load-bearing strength and durability. Dimensional lumber consists of standardized, smaller wood pieces, typically planed and cut to specific sizes for framing and general carpentry. Understanding these key differences helps you select the right material for your building project, ensuring structural integrity and cost efficiency.

Manufacturing Processes

Structural timber undergoes rigorous manufacturing processes including grading, drying, and treating to meet strict strength and durability standards for load-bearing applications. Dimensional lumber is typically milled into standard sizes with less intensive grading, primarily used for non-structural framing and general carpentry tasks. Your choice depends on the specific structural requirements and performance expectations of your construction project.

Common Applications in Construction

Structural timber is commonly used in heavy timber framing, large beams, and glue-laminated (glulam) products for bridges, commercial buildings, and timber trusses, providing high strength and aesthetic appeal. Dimensional lumber, typically standardized in sizes like 2x4 or 2x6, is widely utilized for residential framing, wall studs, floor joists, and roof rafters due to its versatility and ease of handling. Both materials are essential in construction, with structural timber preferred for load-bearing elements requiring superior strength and dimensional lumber favored for routine framing tasks and interior partitions.

Strength and Durability Comparison

Structural timber offers superior strength and durability compared to dimensional lumber due to its larger, continuous grain fibers that resist bending and warping under heavy loads. Dimensional lumber is typically milled to standardized sizes, making it easier to handle but generally less robust for high-stress construction applications. For your building projects requiring long-lasting support and resilience, structural timber provides enhanced load-bearing capabilities and greater resistance to environmental wear.

Sustainability and Environmental Impact

Structural timber offers enhanced sustainability due to its use of engineered wood products that maximize the use of raw materials while reducing waste, unlike traditional dimensional lumber which is often cut from larger, old-growth trees with less efficient resource utilization. Your choice of structural timber supports sustainable forestry practices by promoting faster-growing, renewable wood sources, lowering the carbon footprint associated with construction materials. Environmental impact studies show structural timber contributes to reduced greenhouse gas emissions and increased carbon sequestration compared to conventional dimensional lumber.

Cost Considerations

Structural timber generally costs more than dimensional lumber due to its higher strength, durability, and grading standards, making it ideal for load-bearing applications. Dimensional lumber is often more affordable and readily available, suitable for non-structural projects or interior framing where cost efficiency is a priority. Your choice depends on balancing budget constraints with the specific structural requirements of your construction project.

Availability and Sourcing

Structural timber is often sourced from larger, less processed logs and may be less readily available due to the need for specific grading and treatment standards. Dimensional lumber, standardized in size such as 2x4s or 2x6s, benefits from widespread availability in most retail lumber yards and home improvement stores due to mass production. Regional variations in tree species and forestry regulations influence the sourcing options and cost differences between structural timber and dimensional lumber.

Building Codes and Standards

Building codes and standards strictly regulate both structural timber and dimensional lumber to ensure safety, durability, and performance in construction. Structural timber must comply with specific grading, treatment, and strength requirements outlined in standards such as ASTM D5456 and the International Building Code (IBC). Dimensional lumber, typically standardized in sizes like 2x4 or 2x6, must meet criteria set by entities like the American Lumber Standard Committee (ALSC) and adhere to species-specific grading rules for load-bearing capacity.

Choosing the Right Material for Your Project

Structural timber offers superior strength and durability, making it ideal for heavy-load applications such as beams, posts, and framing in construction projects. Dimensional lumber is more standardized in size, easier to work with, and typically used for residential projects like walls and floors where precise measurements are crucial. Understanding the differences ensures your project benefits from the appropriate material strength, longevity, and ease of installation.

Structural timber vs dimensional lumber Infographic

libmatt.com

libmatt.com