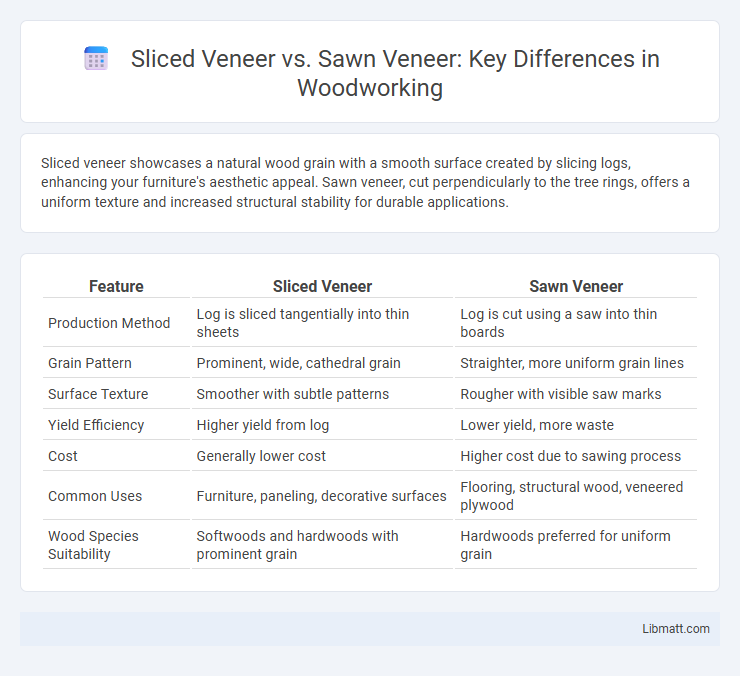

Sliced veneer showcases a natural wood grain with a smooth surface created by slicing logs, enhancing your furniture's aesthetic appeal. Sawn veneer, cut perpendicularly to the tree rings, offers a uniform texture and increased structural stability for durable applications.

Table of Comparison

| Feature | Sliced Veneer | Sawn Veneer |

|---|---|---|

| Production Method | Log is sliced tangentially into thin sheets | Log is cut using a saw into thin boards |

| Grain Pattern | Prominent, wide, cathedral grain | Straighter, more uniform grain lines |

| Surface Texture | Smoother with subtle patterns | Rougher with visible saw marks |

| Yield Efficiency | Higher yield from log | Lower yield, more waste |

| Cost | Generally lower cost | Higher cost due to sawing process |

| Common Uses | Furniture, paneling, decorative surfaces | Flooring, structural wood, veneered plywood |

| Wood Species Suitability | Softwoods and hardwoods with prominent grain | Hardwoods preferred for uniform grain |

Introduction to Veneers: Definitions and Types

Sliced veneer is produced by cutting a log tangentially to create broad, flat sheets with a natural wood grain appearance, commonly used for decorative surfaces. Sawn veneer, also called rotary-cut veneer, involves peeling the log in a rotary lathe to produce continuous thin sheets, often displaying a more uniform and patterned grain. Understanding these veneer types helps you select the right material for furniture, cabinetry, or flooring applications based on aesthetic preferences and durability needs.

What is Sliced Veneer?

Sliced veneer is a type of wood veneer produced by slicing a log tangentially to the growth rings, resulting in a flat sheet with a distinctive grain pattern that highlights the natural character of the wood. This method preserves the figure and texture of the wood, making sliced veneer ideal for decorative surfaces in furniture, cabinetry, and paneling. Compared to sawn veneer, which is cut differently and often has a straighter grain, sliced veneer offers more pronounced and varied grain patterns, enhancing aesthetic appeal.

What is Sawn Veneer?

Sawn veneer is a thin layer of wood cut directly from a log using a saw blade, producing a rougher texture with a more natural wood grain appearance. This type of veneer is thicker than sliced veneer, making it ideal for applications requiring durability and a more rustic aesthetic. You can use sawn veneer in furniture or paneling where a strong, authentic wood look is desired.

Production Processes: Sliced vs Sawn Veneer

Sliced veneer is produced by slicing thin sheets from a log using a large blade, revealing a smooth, consistent grain pattern ideal for decorative surfaces, while sawn veneer is obtained by sawing the log into thin sheets, resulting in a straighter, more linear grain with a slightly rougher texture. The slicing method preserves the natural figure and character of the wood, making sliced veneer highly valued for fine furniture and cabinetry. Understanding these production differences helps you choose the best veneer type for your specific design and application needs.

Grain Patterns and Aesthetic Differences

Sliced veneer produces a broad, flake-like grain pattern that highlights the natural growth rings of the wood, creating a striking and varied visual texture ideal for decorative surfaces. Sawn veneer, cut through the log, features a straight, linear grain pattern that showcases a more uniform and consistent appearance, often preferred for traditional or minimalist designs. Understanding these aesthetic differences helps you select the right veneer to enhance your project's visual appeal and complement your overall design style.

Durability and Structural Integrity

Sliced veneer retains more of the wood's original grain structure, enhancing its durability and maintaining superior structural integrity compared to sawn veneer, which can exhibit increased susceptibility to warping and splitting. The natural grain alignment in sliced veneer provides better resistance to wear and environmental stress, supporting longer-lasting surfaces. Your choice of sliced veneer ensures a balance of aesthetic appeal and robust performance in woodworking projects.

Cost Comparison: Sliced Veneer vs Sawn Veneer

Sliced veneer generally offers a lower cost compared to sawn veneer due to its efficient production process that yields larger sheets with less waste. Sawn veneer, cut directly from logs, often demands higher expenses because of increased labor and material loss during sawing. Your choice between sliced and sawn veneer can impact project budgets, with sliced veneer providing a cost-effective option while maintaining attractive grain patterns.

Applications and Best Uses

Sliced veneer is ideal for decorative applications such as furniture, wall paneling, and cabinetry where a natural wood grain pattern is desired due to its broad, flat cuts that showcase distinctive textures. Sawn veneer, with its uniform thickness and straight grain, is best used in structural projects like plywood cores, flooring, and engineered wood products requiring stability and strength. Your choice between sliced and sawn veneer depends on whether visual aesthetics or mechanical performance is the primary concern.

Environmental Impact and Sustainability

Sliced veneer production generally consumes less energy and generates lower waste compared to sawn veneer, making it a more environmentally friendly choice. Your selection of sliced veneer supports sustainable forestry by maximizing wood usage efficiency and reducing the carbon footprint associated with processing. Choosing sawn veneer may lead to higher material loss and energy consumption, which can negatively impact sustainability efforts in wood manufacturing.

Choosing the Right Veneer for Your Project

Selecting between sliced veneer and sawn veneer depends on your desired wood grain appearance and project requirements. Sliced veneer offers a broad, cathedrals grain pattern ideal for decorative surfaces, while sawn veneer displays a straight, linear grain suited for subtle textures and structural uses. Understanding these differences ensures optimal aesthetic and functional results in cabinetry, furniture, or architectural finishes.

Sliced veneer vs sawn veneer Infographic

libmatt.com

libmatt.com