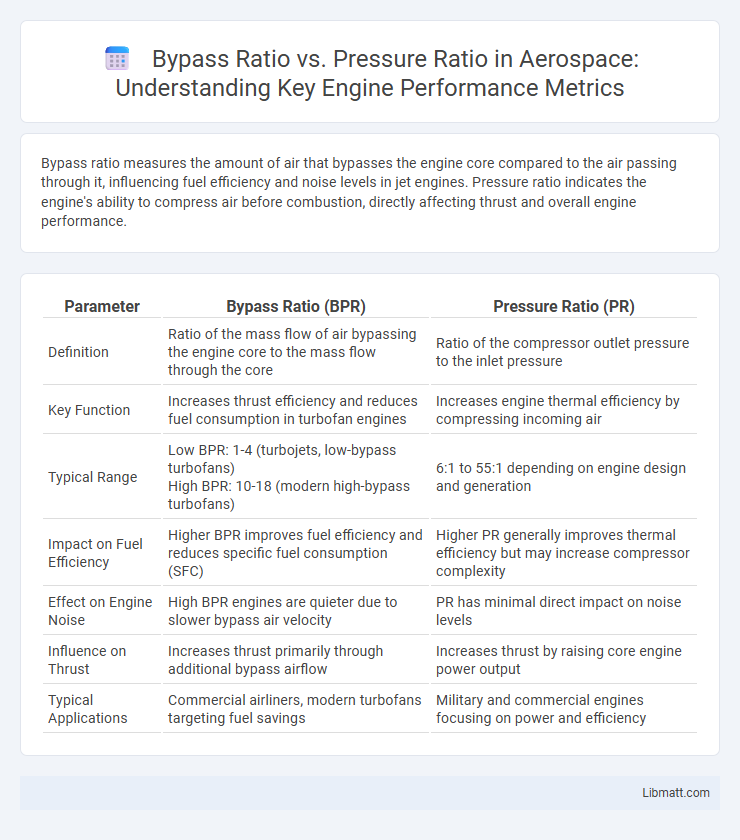

Bypass ratio measures the amount of air that bypasses the engine core compared to the air passing through it, influencing fuel efficiency and noise levels in jet engines. Pressure ratio indicates the engine's ability to compress air before combustion, directly affecting thrust and overall engine performance.

Table of Comparison

| Parameter | Bypass Ratio (BPR) | Pressure Ratio (PR) |

|---|---|---|

| Definition | Ratio of the mass flow of air bypassing the engine core to the mass flow through the core | Ratio of the compressor outlet pressure to the inlet pressure |

| Key Function | Increases thrust efficiency and reduces fuel consumption in turbofan engines | Increases engine thermal efficiency by compressing incoming air |

| Typical Range | Low BPR: 1-4 (turbojets, low-bypass turbofans) High BPR: 10-18 (modern high-bypass turbofans) |

6:1 to 55:1 depending on engine design and generation |

| Impact on Fuel Efficiency | Higher BPR improves fuel efficiency and reduces specific fuel consumption (SFC) | Higher PR generally improves thermal efficiency but may increase compressor complexity |

| Effect on Engine Noise | High BPR engines are quieter due to slower bypass air velocity | PR has minimal direct impact on noise levels |

| Influence on Thrust | Increases thrust primarily through additional bypass airflow | Increases thrust by raising core engine power output |

| Typical Applications | Commercial airliners, modern turbofans targeting fuel savings | Military and commercial engines focusing on power and efficiency |

Introduction to Bypass Ratio and Pressure Ratio

Bypass ratio measures the amount of air bypassing the engine core compared to the air passing through the core, significantly impacting fuel efficiency and thrust in turbofan engines. Pressure ratio refers to the ratio of the compressor outlet pressure to the inlet pressure, directly influencing engine performance, thermal efficiency, and thrust production. Understanding the relationship between bypass ratio and pressure ratio is essential for optimizing jet engine design to balance fuel economy and power output.

Understanding Bypass Ratio in Jet Engines

Bypass ratio in jet engines quantifies the mass of air bypassing the combustion chamber compared to the mass passing through it, directly influencing fuel efficiency and noise reduction. Higher bypass ratios indicate larger volumes of cooler air flowing around the core, enhancing thrust through increased propulsive efficiency and reducing specific fuel consumption. Understanding the bypass ratio's role alongside pressure ratio reveals how modern turbofan engines balance airflow dynamics to optimize overall engine performance and emissions.

Defining Pressure Ratio and Its Importance

Pressure ratio, defined as the ratio of the compressor outlet pressure to the inlet pressure, is a critical parameter in jet engine performance, directly impacting engine efficiency and thrust generation. A higher pressure ratio improves the thermodynamic efficiency of the engine cycle, resulting in better fuel economy and increased power output. Understanding how pressure ratio interacts with bypass ratio enables you to optimize engine design for specific performance goals, balancing fuel consumption and thrust requirements effectively.

Key Differences Between Bypass Ratio and Pressure Ratio

Bypass Ratio refers to the ratio of the mass flow rate of air that bypasses the engine core to the mass flow passing through the core, significantly affecting engine efficiency and noise levels. Pressure Ratio measures the increase in air pressure from the engine inlet to the compressor outlet, directly influencing thrust and fuel consumption. Understanding these key differences helps you optimize engine performance based on your specific aviation or engineering requirements.

Impact on Engine Efficiency and Performance

Higher bypass ratios improve engine efficiency by increasing thrust without significantly raising fuel consumption, making them ideal for commercial airliners prioritizing fuel economy. Conversely, higher pressure ratios enhance engine performance by increasing thermal efficiency and power output, benefiting military jets and supersonic aircraft requiring greater speed and altitude capabilities. Your engine choice depends on the balance between fuel efficiency and performance demands dictated by mission profiles.

Influence on Fuel Consumption and Emissions

A higher bypass ratio typically improves fuel efficiency by increasing the mass of bypass air, reducing specific fuel consumption and lowering CO2 emissions in turbofan engines. Conversely, an increased pressure ratio enhances thermal efficiency, resulting in better fuel burn rates but can lead to higher NOx emissions due to elevated combustion temperatures. Balancing bypass and pressure ratios is critical in modern engine design to optimize environmental performance while minimizing both fuel consumption and pollutant emissions.

Applications in Commercial vs. Military Aviation

Bypass ratio plays a critical role in commercial aviation, where high bypass engines optimize fuel efficiency and reduce noise for long-haul flights, while pressure ratio influences engine overall thermal efficiency. Military aviation favors engines with lower bypass ratios and higher pressure ratios to achieve superior thrust-to-weight ratios and enhanced performance for supersonic speeds and combat maneuverability. The contrast between high bypass ratio turbofans in commercial airliners and low bypass, high-pressure ratio turbojets in military jets underlines their distinct priorities of fuel economy versus maximum thrust.

Technological Trends in Engine Design

Modern engine design trends emphasize increasing bypass ratios to enhance fuel efficiency and reduce noise while optimizing pressure ratios to improve thermal efficiency and thrust generation. High bypass ratio turbofans achieve better propulsive efficiency by moving larger air masses at lower speeds, aligning with stringent environmental regulations and fuel economy demands. Your understanding of the balance between bypass ratio and pressure ratio is crucial for appreciating advancements in next-generation commercial and military aircraft engines.

Challenges and Considerations in Optimization

Optimization of bypass ratio and pressure ratio in turbofan engines requires balancing fuel efficiency, thrust output, and noise regulations. High bypass ratios improve propulsive efficiency but often limit achievable pressure ratios, impacting overall thermal efficiency. Engine designers must consider material limitations and cooling requirements to avoid compromising durability when increasing pressure ratios.

Future Outlook: Evolving Engine Parameters

Future jet engines are expected to balance higher bypass ratios with optimized pressure ratios to achieve superior fuel efficiency and reduced emissions. Advances in materials and aerodynamics enable manufacturers to push bypass ratios beyond 15:1 while maintaining pressure ratios that exceed 50:1 in next-generation turbofans. Your aircraft's performance and environmental impact will benefit from these evolving engine parameters, reflecting ongoing innovations in propulsion technology.

Bypass Ratio vs Pressure Ratio Infographic

libmatt.com

libmatt.com