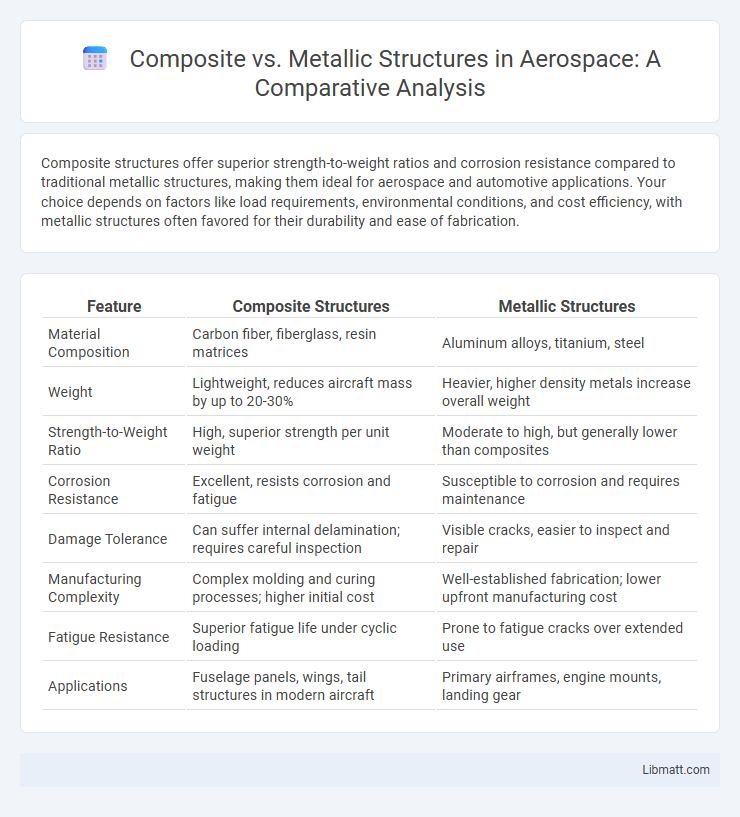

Composite structures offer superior strength-to-weight ratios and corrosion resistance compared to traditional metallic structures, making them ideal for aerospace and automotive applications. Your choice depends on factors like load requirements, environmental conditions, and cost efficiency, with metallic structures often favored for their durability and ease of fabrication.

Table of Comparison

| Feature | Composite Structures | Metallic Structures |

|---|---|---|

| Material Composition | Carbon fiber, fiberglass, resin matrices | Aluminum alloys, titanium, steel |

| Weight | Lightweight, reduces aircraft mass by up to 20-30% | Heavier, higher density metals increase overall weight |

| Strength-to-Weight Ratio | High, superior strength per unit weight | Moderate to high, but generally lower than composites |

| Corrosion Resistance | Excellent, resists corrosion and fatigue | Susceptible to corrosion and requires maintenance |

| Damage Tolerance | Can suffer internal delamination; requires careful inspection | Visible cracks, easier to inspect and repair |

| Manufacturing Complexity | Complex molding and curing processes; higher initial cost | Well-established fabrication; lower upfront manufacturing cost |

| Fatigue Resistance | Superior fatigue life under cyclic loading | Prone to fatigue cracks over extended use |

| Applications | Fuselage panels, wings, tail structures in modern aircraft | Primary airframes, engine mounts, landing gear |

Introduction to Composite and Metallic Structures

Composite structures combine materials like carbon fiber and resin to achieve high strength-to-weight ratios, ideal for aerospace and automotive applications. Metallic structures, typically made from steel or aluminum, offer excellent ductility and durability, suitable for heavy load-bearing frameworks. Understanding the fundamental properties of both helps you select the optimal material based on performance requirements and environmental conditions.

Material Properties: Composites vs Metals

Composite materials exhibit high strength-to-weight ratios, excellent corrosion resistance, and tailored stiffness through fiber orientation, making them ideal for aerospace and automotive applications where weight reduction is critical. Metallic structures, primarily composed of aluminum, steel, and titanium alloys, provide superior ductility, impact resistance, and thermal conductivity but tend to be heavier and more prone to corrosion without protective coatings. The anisotropic nature of composites contrasts with the isotropic behavior of metals, influencing design considerations such as fatigue performance and load distribution in structural engineering.

Weight and Structural Efficiency

Composite structures offer superior weight savings and enhanced structural efficiency compared to metallic structures due to their high strength-to-weight ratio and tailored material properties. These materials allow for optimized load distribution and reduced mass, improving overall performance and fuel efficiency in applications such as aerospace and automotive engineering. Your choice of composite over metallic structures can result in significant benefits in durability and weight reduction without compromising strength.

Durability and Corrosion Resistance

Composite structures offer superior corrosion resistance compared to metallic structures, making them ideal for harsh environments where moisture and chemicals are prevalent. Metallic structures, particularly those made from steel or aluminum, require protective coatings or treatments to prevent rust and degradation over time. Your choice between composite and metallic materials will impact long-term durability, maintenance costs, and structural integrity in corrosive settings.

Manufacturing and Production Processes

Composite structures are created through layered fabrication methods such as hand lay-up, resin transfer molding (RTM), and automated fiber placement, which enable tailored strength-to-weight ratios and complex geometries. Metallic structures utilize traditional processes including casting, forging, machining, and welding, offering high strength and durability but often with increased weight. Advanced manufacturing technologies like additive manufacturing and hybrid joining are bridging production efficiencies between composite and metallic materials.

Cost Considerations

Composite structures often incur higher initial manufacturing costs due to expensive raw materials and specialized fabrication techniques. Metallic structures benefit from lower material costs and established production processes, resulting in reduced upfront expenses. Long-term cost efficiency in composites arises from corrosion resistance and lower maintenance requirements, offsetting initial investments over the product lifecycle.

Maintenance and Repair Challenges

Composite structures pose unique maintenance challenges due to their susceptibility to delamination, moisture absorption, and UV degradation, requiring specialized inspection techniques such as ultrasonic testing and thermography. Metallic structures often experience corrosion and fatigue cracks, which are typically easier to detect and repair using conventional welding and patching methods. Your maintenance strategy must consider these differences to ensure reliability, cost-effectiveness, and longevity of the structure.

Performance in Aerospace and Automotive Industries

Composite structures offer superior strength-to-weight ratios and corrosion resistance, making them ideal for aerospace and automotive industries seeking fuel efficiency and durability. Metallic structures provide excellent impact resistance and thermal conductivity, essential for high-stress applications and engine components. Your choice between composite and metallic materials depends on balancing weight savings with mechanical performance requirements in these sectors.

Environmental Impact and Sustainability

Composite structures offer significant environmental benefits due to their lightweight nature, leading to reduced fuel consumption and lower carbon emissions in transportation applications. Metallic structures, while durable and recyclable, often require energy-intensive extraction and manufacturing processes that contribute to higher environmental footprints. Your choice between these materials can affect sustainability goals, with composites promoting energy efficiency and metal recycling supporting circular economy practices.

Future Trends in Structural Materials

Future trends in structural materials emphasize the increasing adoption of composite structures due to their superior strength-to-weight ratio, corrosion resistance, and design flexibility compared to traditional metallic structures. Advances in nanotechnology and smart materials are enhancing the performance and sustainability of composites, enabling lighter, more durable, and multifunctional components for aerospace, automotive, and civil engineering applications. Your choice of structural materials will increasingly depend on balancing cost, environmental impact, and performance requirements as innovations continue to shift industry standards.

Composite vs Metallic Structures Infographic

libmatt.com

libmatt.com