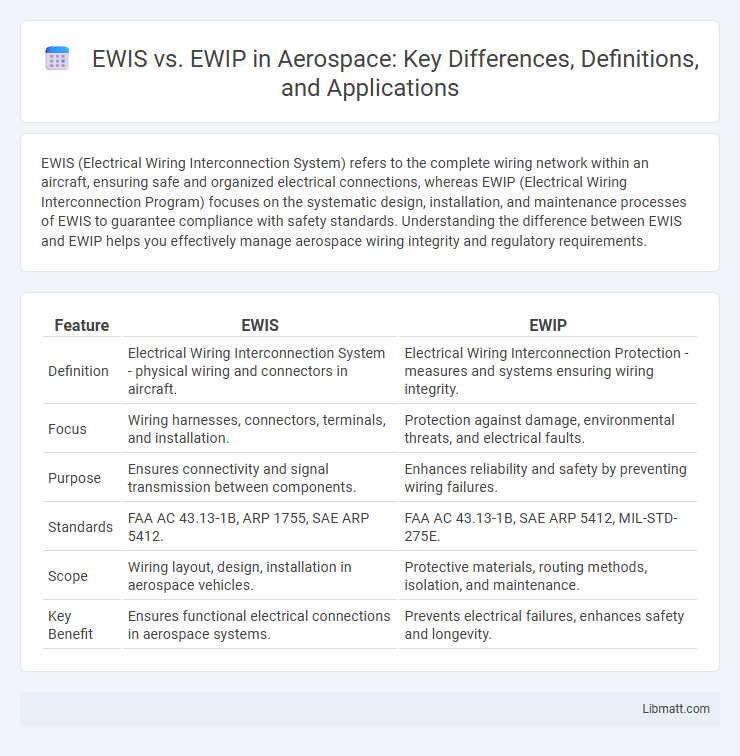

EWIS (Electrical Wiring Interconnection System) refers to the complete wiring network within an aircraft, ensuring safe and organized electrical connections, whereas EWIP (Electrical Wiring Interconnection Program) focuses on the systematic design, installation, and maintenance processes of EWIS to guarantee compliance with safety standards. Understanding the difference between EWIS and EWIP helps you effectively manage aerospace wiring integrity and regulatory requirements.

Table of Comparison

| Feature | EWIS | EWIP |

|---|---|---|

| Definition | Electrical Wiring Interconnection System - physical wiring and connectors in aircraft. | Electrical Wiring Interconnection Protection - measures and systems ensuring wiring integrity. |

| Focus | Wiring harnesses, connectors, terminals, and installation. | Protection against damage, environmental threats, and electrical faults. |

| Purpose | Ensures connectivity and signal transmission between components. | Enhances reliability and safety by preventing wiring failures. |

| Standards | FAA AC 43.13-1B, ARP 1755, SAE ARP 5412. | FAA AC 43.13-1B, SAE ARP 5412, MIL-STD-275E. |

| Scope | Wiring layout, design, installation in aerospace vehicles. | Protective materials, routing methods, isolation, and maintenance. |

| Key Benefit | Ensures functional electrical connections in aerospace systems. | Prevents electrical failures, enhances safety and longevity. |

Introduction to EWIS and EWIP

EWIS (Electrical Wiring Interconnection System) encompasses the design, installation, and maintenance of wiring systems in aircraft to ensure safety and functionality. EWIP (Electrical Wiring Interconnection Program) focuses on the systematic inspection and maintenance practices aimed at mitigating wiring defects and failures within EWIS. Understanding the distinction between EWIS and EWIP helps you optimize aircraft electrical system reliability and compliance with regulatory standards.

Defining EWIS: Electrical Wiring Interconnection System

Electrical Wiring Interconnection System (EWIS) refers to the organized network of electrical wires, connectors, and associated components designed to ensure reliable power distribution and signal transmission within an aircraft or complex machinery. EWIS standards emphasize safety, durability, and ease of maintenance to prevent failures and electrical hazards. Understanding EWIS helps you optimize system integrity and comply with aviation industry regulations.

Defining EWIP: Electrical Wiring Interconnection Practice

Electrical Wiring Interconnection Practice (EWIP) refers to the standardized methods and procedures for designing, installing, and maintaining aircraft electrical wiring systems to ensure safety and reliability. Unlike Electrical Wiring Interconnection Systems (EWIS), which primarily describes the physical components and harnesses, EWIP emphasizes best practices, guidelines, and quality controls throughout the wiring lifecycle. Adhering to EWIP standards reduces risks of wiring failures and enhances compliance with regulatory aviation safety requirements.

Key Differences Between EWIS and EWIP

EWIS (Electrical Wiring Interconnection System) refers to the physical components and architecture of wiring systems within aircraft, emphasizing design, installation, and maintenance standards. EWIP (Electrical Wiring Interconnection Program) focuses on the management process, including risk assessment, inspection, and ongoing maintenance to ensure wiring system reliability and safety. Understanding these distinctions helps you optimize both the structural integrity and operational safety of aerospace electrical systems.

Importance of EWIS in Modern Aircraft

EWIS (Electrical Wiring Interconnection Systems) is crucial in modern aircraft for ensuring reliable power distribution and signal transmission between avionics and control systems. Unlike EWIP (Electrical Wiring Interconnection Panels), which are primarily connection hubs, EWIS encompasses the entire wiring architecture, emphasizing safety, durability, and maintenance ease. Understanding the importance of EWIS helps you maintain aircraft integrity and prevent electrical failures that could compromise flight safety.

The Role of EWIP in Aviation Safety

EWIP (Electrical Wiring Interconnection Protection) enhances aviation safety by preventing electrical faults that can lead to system failures or fires, surpassing traditional EWIS (Electrical Wiring Interconnection Systems) in safeguarding aircraft wiring integrity. By integrating advanced monitoring and shielding techniques, EWIP reduces the risk of arc faults and electrical shorts, which are critical causes of in-flight malfunctions. Your aircraft's safety depends on the proactive implementation of EWIP standards to ensure reliable electrical system performance and compliance with stringent industry regulations.

Regulatory Standards for EWIS and EWIP

Regulatory standards for EWIS (Electrical Wiring Interconnection Systems) and EWIP (Electrical Wiring Interconnection Product) ensure the reliability and safety of aircraft electrical systems through strict certification requirements set by authorities such as the FAA and EASA. EWIS standards focus on the installation, maintenance, and inspection of wiring harnesses to prevent hazards like chafing and short circuits, while EWIP standards pertain to the design, manufacturing, and quality control of wiring products used in these systems. Compliance with these regulatory frameworks is essential to maintain airworthiness and operational integrity, directly impacting Your aircraft's electrical system performance.

Implementation Challenges and Solutions

EWIS (Electrical Wiring Interconnection System) and EWIP (Electrical Wiring Interconnect Panel) both face challenges such as complexity in design, weight constraints, and maintenance difficulties. Effective solutions include adopting standardized design protocols, using lightweight composite materials to reduce weight, and implementing advanced diagnostic tools for quicker fault detection. Your aerospace projects can benefit from integrating these strategies to streamline implementation and enhance system reliability.

Future Trends in Aircraft Wiring Systems

Future trends in aircraft wiring systems emphasize the transition from Electrical Wiring Interconnection Systems (EWIS) to Electrical Wiring Interconnection Products (EWIP), driven by advancements in miniaturization, enhanced durability, and improved grounding techniques. EWIP solutions reduce overall aircraft weight and improve reliability by integrating connectors, terminals, and wires into streamlined assemblies. Your aircraft maintenance and design strategies will benefit from embracing EWIP innovations to meet evolving safety standards and reduce lifecycle costs.

Conclusion: Choosing Between EWIS and EWIP

Choosing between an Electrical Wiring Interconnection System (EWIS) and an Electrical Wiring Interconnection Package (EWIP) depends largely on project scope and integration needs. EWIS focuses on the detailed components and architecture of wiring systems essential for aviation safety standards, while EWIP delivers a comprehensive, ready-to-install assembly that reduces installation time and error. For streamlined assembly and enhanced reliability in complex aerospace projects, EWIP is more advantageous; however, EWIS provides critical customization and control for detailed engineering and maintenance.

EWIS vs EWIP Infographic

libmatt.com

libmatt.com