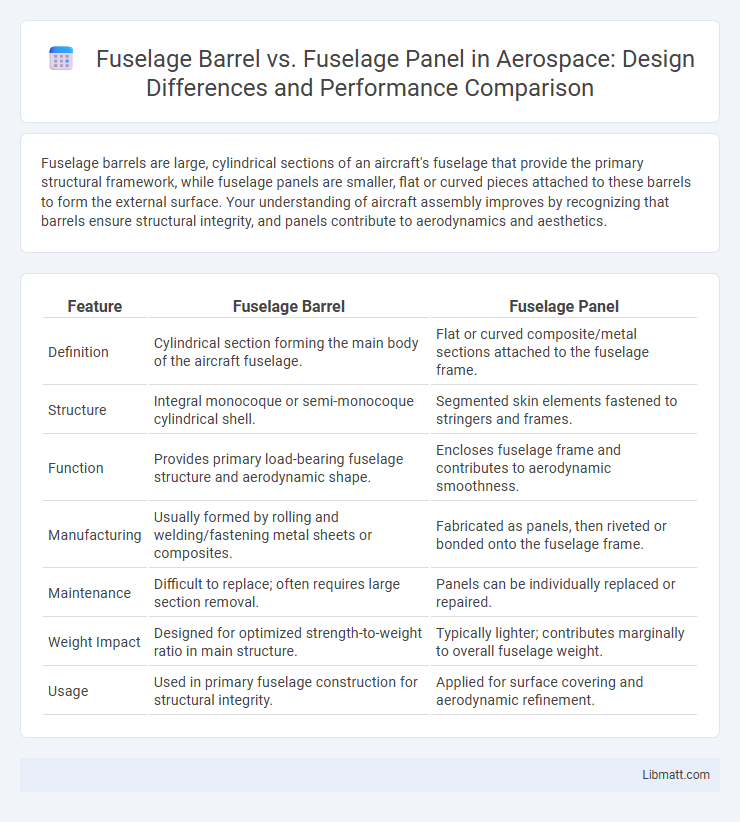

Fuselage barrels are large, cylindrical sections of an aircraft's fuselage that provide the primary structural framework, while fuselage panels are smaller, flat or curved pieces attached to these barrels to form the external surface. Your understanding of aircraft assembly improves by recognizing that barrels ensure structural integrity, and panels contribute to aerodynamics and aesthetics.

Table of Comparison

| Feature | Fuselage Barrel | Fuselage Panel |

|---|---|---|

| Definition | Cylindrical section forming the main body of the aircraft fuselage. | Flat or curved composite/metal sections attached to the fuselage frame. |

| Structure | Integral monocoque or semi-monocoque cylindrical shell. | Segmented skin elements fastened to stringers and frames. |

| Function | Provides primary load-bearing fuselage structure and aerodynamic shape. | Encloses fuselage frame and contributes to aerodynamic smoothness. |

| Manufacturing | Usually formed by rolling and welding/fastening metal sheets or composites. | Fabricated as panels, then riveted or bonded onto the fuselage frame. |

| Maintenance | Difficult to replace; often requires large section removal. | Panels can be individually replaced or repaired. |

| Weight Impact | Designed for optimized strength-to-weight ratio in main structure. | Typically lighter; contributes marginally to overall fuselage weight. |

| Usage | Used in primary fuselage construction for structural integrity. | Applied for surface covering and aerodynamic refinement. |

Introduction: Fuselage Barrel vs Fuselage Panel

Fuselage barrels are large cylindrical sections forming the primary load-bearing structure of an aircraft's fuselage, providing strength and aerodynamic shape. Fuselage panels are smaller, removable sections attached to the barrel, allowing easy access for maintenance and housing secondary structures like doors and windows. Understanding the distinction between these components helps optimize your aircraft's design efficiency and maintenance strategy.

Historical Evolution of Fuselage Design

Fuselage barrels revolutionized aircraft construction by introducing large, cylindrical sections that enhanced structural integrity and simplified assembly in the mid-20th century. Earlier designs relied on fuselage panels, which involved assembling multiple smaller sections, often increasing complexity and weight. Understanding the evolution from fuselage panels to barrels can help you appreciate advancements in aeronautical engineering and modern aircraft durability.

Fundamental Differences: Barrel and Panel Construction

Fuselage barrels are large, cylindrical sections of an aircraft fuselage, typically made from multiple panels riveted or bonded together, providing structural integrity and streamlined shape. Fuselage panels are flat or slightly curved sheets that form the outer skin of the fuselage, attached to the underlying frames and stringers to create the overall barrel shape. The fundamental difference lies in barrels being assembled sections composed of panels, while panels are the individual components used in the construction of these barrels.

Structural Integrity and Load Distribution

Fuselage barrels provide enhanced structural integrity by forming continuous cylindrical sections that evenly distribute aerodynamic and pressurization loads throughout the aircraft's frame. Fuselage panels, while offering flexibility in assembly and maintenance, rely on precise fastening and reinforcement to manage localized stresses and prevent load concentration. Your choice between the two affects the overall durability and performance under operational stress conditions.

Manufacturing Processes and Complexity

Fuselage barrels involve the manufacturing of large cylindrical sections formed by assembling multiple panels through advanced processes such as automated riveting or friction stir welding, requiring high precision and specialized tooling. Fuselage panels are smaller, flat or slightly curved components produced using sheet metal forming techniques like stamping or hydroforming, which generally allow for simpler and faster fabrication. The complexity in manufacturing fuselage barrels is significantly higher due to the need for precise alignment and handling of larger structures, whereas panels benefit from modularity and easier integration.

Weight Efficiency and Material Utilization

Fuselage barrels offer superior weight efficiency by integrating long, cylindrical sections that reduce the number of joints and fasteners, minimizing structural redundancies and maximizing load distribution. Fuselage panels, while more modular and easier to manufacture in smaller batches, often result in increased weight due to overlapping materials and additional reinforcement at panel edges. Material utilization in fuselage barrels is optimized through streamlined manufacturing processes like automated fiber placement, whereas fuselage panels may experience greater scrap rates and higher cumulative weight from overlapping segments.

Assembly Time and Production Scalability

Fuselage barrels streamline assembly time by integrating large, pre-assembled cylindrical sections, reducing the number of joints and fastening operations compared to multiple fuselage panels. Production scalability benefits as barrel construction allows for automation in manufacturing processes, enabling faster throughput and consistent quality in high-volume aircraft production. In contrast, fuselage panels require more manual labor and complex alignment, which can increase assembly time and limit scalability in large-scale manufacturing.

Maintenance, Repair, and Modifications

Fuselage barrels provide a larger, continuous structural section, simplifying maintenance and major repairs by allowing for easier access and replacement of extensive damage areas. Fuselage panels, being smaller segmented components, enable targeted repairs and modifications with minimal disruption to adjacent structures, reducing downtime and maintenance complexity. Your choice between barrel and panel configurations impacts repair efficiency, cost, and the flexibility of modifications during aircraft maintenance cycles.

Cost Analysis: Initial and Lifecycle Expenses

Fuselage barrels generally incur higher initial manufacturing costs due to their complex tooling and assembly processes compared to fuselage panels, which are simpler and quicker to produce. Lifecycle expenses for fuselage barrels tend to be lower because their structural integrity reduces maintenance frequency and increases durability, whereas fuselage panels may require more frequent inspections and repairs, raising long-term costs. Understanding the balance between upfront investment and ongoing maintenance will help you optimize your aircraft's overall cost efficiency.

Future Trends in Aircraft Fuselage Development

Future trends in aircraft fuselage development emphasize lightweight composite materials to improve fuel efficiency and reduce emissions. Fuselage barrels, typically large cylindrical sections, are increasingly manufactured using automated fiber placement to enhance structural integrity and production speed. Fuselage panels, integral to modular designs, enable easier maintenance and customization, supporting the shift towards more flexible and sustainable aerospace manufacturing processes.

Fuselage barrel vs Fuselage panel Infographic

libmatt.com

libmatt.com