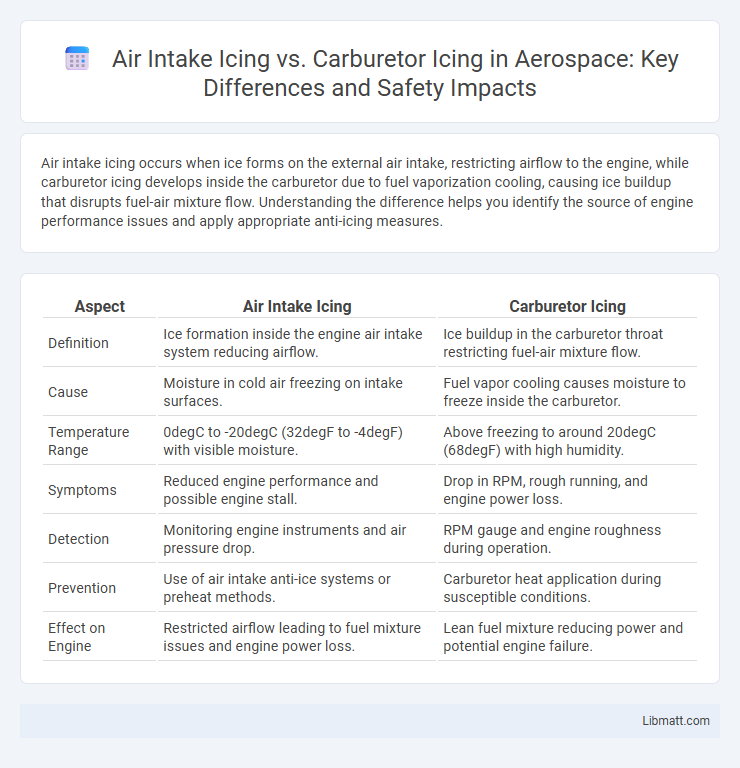

Air intake icing occurs when ice forms on the external air intake, restricting airflow to the engine, while carburetor icing develops inside the carburetor due to fuel vaporization cooling, causing ice buildup that disrupts fuel-air mixture flow. Understanding the difference helps you identify the source of engine performance issues and apply appropriate anti-icing measures.

Table of Comparison

| Aspect | Air Intake Icing | Carburetor Icing |

|---|---|---|

| Definition | Ice formation inside the engine air intake system reducing airflow. | Ice buildup in the carburetor throat restricting fuel-air mixture flow. |

| Cause | Moisture in cold air freezing on intake surfaces. | Fuel vapor cooling causes moisture to freeze inside the carburetor. |

| Temperature Range | 0degC to -20degC (32degF to -4degF) with visible moisture. | Above freezing to around 20degC (68degF) with high humidity. |

| Symptoms | Reduced engine performance and possible engine stall. | Drop in RPM, rough running, and engine power loss. |

| Detection | Monitoring engine instruments and air pressure drop. | RPM gauge and engine roughness during operation. |

| Prevention | Use of air intake anti-ice systems or preheat methods. | Carburetor heat application during susceptible conditions. |

| Effect on Engine | Restricted airflow leading to fuel mixture issues and engine power loss. | Lean fuel mixture reducing power and potential engine failure. |

Understanding Air Intake Icing and Carburetor Icing

Air intake icing occurs when moisture in the outside air freezes within the engine's air intake system, restricting airflow and reducing engine performance. Carburetor icing specifically happens when the fuel vaporizes in the carburetor throat, causing a temperature drop that freezes moisture and blocks the venturi, leading to engine power loss or failure. Recognizing the differences in location and formation between air intake icing and carburetor icing is crucial for effective prevention and engine safety during flight operations.

Key Differences Between Air Intake Icing and Carburetor Icing

Air intake icing occurs when ice forms within the engine's air intake system, restricting airflow and reducing engine performance, while carburetor icing specifically happens inside the carburetor, where fuel vapor and air mix, leading to ice buildup that disrupts fuel delivery and engine operation. Air intake icing generally affects the entire engine air supply, whereas carburetor icing is localized and influenced by the fuel-air mixture temperature. Understanding these key differences is crucial for pilots, as the prevention and mitigation techniques vary, with carburetor heat commonly used to combat carburetor icing.

Causes of Air Intake Icing

Air intake icing occurs when moisture in the air freezes upon contact with cold surfaces in the engine's air intake system, often caused by temperatures between -7degC and 21degC combined with high humidity. This ice buildup restricts airflow, leading to a decrease in engine performance or possible engine stall. You can prevent air intake icing by monitoring environmental conditions and using anti-icing systems or carburetor heat as appropriate.

Causes of Carburetor Icing

Carburetor icing occurs when moist air cools rapidly inside the carburetor, causing water vapor to freeze on the carburetor throat and throttle plate. This phenomenon is primarily caused by the pressure drop and fuel vaporization, which lower the temperature below freezing even in ambient conditions up to 70degF (21degC) with high humidity. Understanding these specific conditions helps pilots anticipate and prevent carburetor ice formation during flight.

Signs and Symptoms of Air Intake Icing

Air intake icing manifests through a noticeable reduction in engine power and rough engine operation, often accompanied by fluctuating RPM or manifold pressure. Pilots may observe increased fuel consumption and difficulty maintaining engine temperature, particularly in humid, cold environments where ice accumulates on intake screens or ducts. Visual indicators include frost or ice buildup around the air filter or intake openings, signaling restricted airflow that compromises engine performance.

Detecting Carburetor Icing in Aircraft

Detecting carburetor icing in aircraft involves monitoring changes in engine performance such as a drop in RPM, rough running, or a loss of power during flight, especially in conditions of high humidity and temperatures between -7degC and 21degC (20degF to 70degF). You can often identify carburetor icing by observing an increase in intake air temperature gauge readings alongside reduced engine output. Prompt use of carburetor heat helps prevent ice buildup by warming the incoming air, ensuring safer engine operation.

Effects on Engine Performance: Air Intake vs. Carburetor Icing

Air intake icing restricts the airflow to the engine, causing a significant reduction in power output and increased fuel consumption due to incomplete combustion. Carburetor icing disrupts the fuel-air mixture by blocking the venturi, leading to rough engine idling, loss of RPM, and potential engine stalling. Understanding these differences helps you identify and address the specific icing issue to maintain optimal engine performance and safety.

Prevention Strategies for Air Intake Icing

Effective prevention strategies for air intake icing include using heated air intakes or carburetor heat systems to maintain temperature above freezing, ensuring continuous airflow, and monitoring environmental conditions like humidity and temperature. Installing intake air temperature sensors helps detect early icing formation, allowing timely activation of anti-icing measures. Your aircraft's operational planning should incorporate preflight checks focusing on potential ice buildup to enhance safety and engine performance.

Managing and Preventing Carburetor Icing

Carburetor icing occurs when moisture in the air freezes inside the carburetor, restricting airflow and reducing engine performance, especially in humid and cold conditions. Managing carburetor icing involves routinely applying carburetor heat as recommended, which helps melt ice buildup and restore proper air-fuel mixture flow. Your ability to recognize initial signs of icing, such as a drop in engine RPM or rough running, is crucial for timely intervention and safe operation.

Safety Tips for Pilots: Dealing with Icing Hazards

Pilots must recognize that air intake icing reduces engine performance by restricting airflow, while carburetor icing disrupts fuel-air mixture, potentially causing engine failure. Monitoring temperature and humidity conditions below 70degF and above 80% relative humidity enables early detection and activation of carburetor heat to prevent ice buildup. Regularly inspecting air intake filters and applying anti-icing systems improve safety by maintaining engine efficiency and avoiding hazardous power loss during critical flight phases.

air intake icing vs carburetor icing Infographic

libmatt.com

libmatt.com