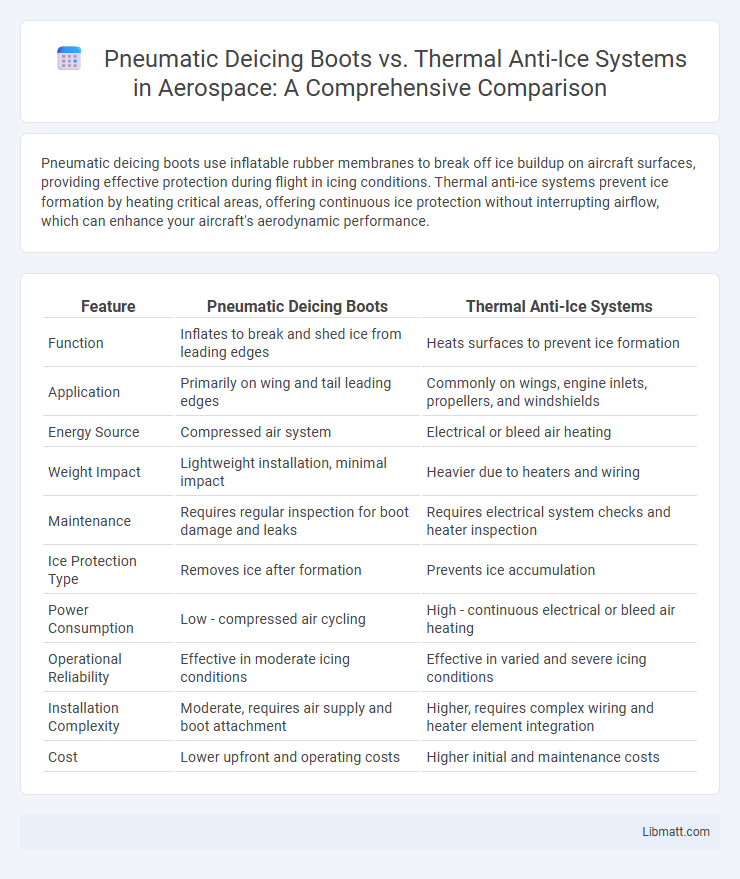

Pneumatic deicing boots use inflatable rubber membranes to break off ice buildup on aircraft surfaces, providing effective protection during flight in icing conditions. Thermal anti-ice systems prevent ice formation by heating critical areas, offering continuous ice protection without interrupting airflow, which can enhance your aircraft's aerodynamic performance.

Table of Comparison

| Feature | Pneumatic Deicing Boots | Thermal Anti-Ice Systems |

|---|---|---|

| Function | Inflates to break and shed ice from leading edges | Heats surfaces to prevent ice formation |

| Application | Primarily on wing and tail leading edges | Commonly on wings, engine inlets, propellers, and windshields |

| Energy Source | Compressed air system | Electrical or bleed air heating |

| Weight Impact | Lightweight installation, minimal impact | Heavier due to heaters and wiring |

| Maintenance | Requires regular inspection for boot damage and leaks | Requires electrical system checks and heater inspection |

| Ice Protection Type | Removes ice after formation | Prevents ice accumulation |

| Power Consumption | Low - compressed air cycling | High - continuous electrical or bleed air heating |

| Operational Reliability | Effective in moderate icing conditions | Effective in varied and severe icing conditions |

| Installation Complexity | Moderate, requires air supply and boot attachment | Higher, requires complex wiring and heater element integration |

| Cost | Lower upfront and operating costs | Higher initial and maintenance costs |

Introduction to Aircraft Ice Protection Systems

Aircraft ice protection systems include pneumatic deicing boots and thermal anti-ice technologies, each designed to prevent ice accumulation on critical surfaces. Pneumatic deicing boots use inflatable rubber sections to mechanically break and shed ice, primarily on wing leading edges. Thermal anti-ice systems employ electrical heating elements or hot bleed air to continuously prevent ice formation, offering seamless protection under diverse icing conditions.

Understanding Pneumatic Deicing Boots

Pneumatic deicing boots use inflatable rubber membranes installed on aircraft wings and tail surfaces to break and shed ice accumulation during flight. These boots operate by rapidly inflating and deflating to crack and remove ice, ensuring safer aerodynamics and maintaining lift. Your choice between pneumatic deicing boots and thermal anti-ice systems depends on factors like aircraft type, weight considerations, and operational environment.

How Thermal Anti-Ice Systems Work

Thermal anti-ice systems work by electrically heating critical aircraft surfaces such as leading edges of wings and engine inlets to prevent ice formation during flight. These systems use embedded heating elements or bleed air ducting to maintain a surface temperature above freezing, ensuring continuous ice prevention rather than relying on ice removal. Compared to pneumatic deicing boots, thermal systems provide seamless protection and reduce aerodynamic disturbances caused by boot inflation cycles, enhancing your aircraft's safety and performance in icing conditions.

Key Differences Between Pneumatic and Thermal Systems

Pneumatic deicing boots operate by inflating rubber surfaces on aircraft leading edges to physically dislodge accumulated ice, while thermal anti-ice systems use electrical heating elements or hot air to prevent ice formation altogether. Pneumatic systems are typically more effective in shedding ice after it forms, requiring less continuous power, whereas thermal systems offer continuous protection by maintaining surface temperatures above freezing but demand higher energy consumption. The choice between these systems depends on aircraft design, operational environment, and the balance between weight, power availability, and maintenance considerations.

Effectiveness in Various Icing Conditions

Pneumatic deicing boots provide effective protection against moderate to severe rime and mixed ice by mechanically expanding to break ice accumulation, making them reliable in intermittent icing conditions. Thermal anti-ice systems prevent ice formation by applying heat, excelling in continuous, severe freezing rain and clear ice conditions where mechanical methods might struggle. The choice between these systems depends on aircraft type, expected icing severity, and mission requirements, with thermal anti-ice offering superior performance in sustained freezing precipitation.

Maintenance and Operational Considerations

Pneumatic deicing boots require regular inspection for tears, leaks, and valve functionality to ensure reliable inflation during ice accumulation, making their maintenance moderately intensive but straightforward. Thermal anti-ice systems involve more complex components like heating elements and sensors, which demand detailed electrical system checks and potentially higher repair costs due to their intricate design. Operationally, pneumatic boots impose periodic inflation cycles that may momentarily affect aerodynamics, whereas thermal systems provide continuous ice prevention with consistent energy consumption, influencing fuel efficiency and system monitoring protocols.

Impact on Aircraft Performance and Efficiency

Pneumatic deicing boots add weight and aerodynamic drag, leading to increased fuel consumption and reduced climb performance during activation. Thermal anti-ice systems, while consuming significant electrical or bleed air power, provide continuous ice protection with less impact on drag but can reduce engine efficiency due to bleed air extraction. Both systems influence aircraft efficiency differently, with pneumatic boots affecting aerodynamics and thermal systems impacting power management.

Cost Comparison: Installation and Operation

Pneumatic deicing boots generally have lower upfront installation costs compared to thermal anti-ice systems, which require more complex electrical and structural modifications. Operational expenses for pneumatic boots tend to be lower due to minimal power consumption, while thermal anti-ice systems consume significant electrical energy, increasing ongoing costs. Your choice depends on balancing initial investment with long-term operational efficiency and maintenance requirements.

Safety and Reliability Analysis

Pneumatic deicing boots provide reliable ice removal by mechanically breaking ice accumulation with inflation cycles, ensuring consistent wing surface clarity during flight. Thermal anti-ice systems offer continuous prevention of ice formation using electrical or bleed air heating, reducing the risk of ice adherence and maintaining aerodynamic efficiency. Safety analysis indicates pneumatic boots excel in post-icing removal scenarios while thermal anti-ice systems perform better in preemptive ice prevention, making their combined use optimal for comprehensive ice protection.

Choosing the Right System for Your Aircraft

Pneumatic deicing boots effectively remove ice buildup by inflating rubber bladders on wing leading edges, ideal for smaller aircraft operating in intermittent icing conditions. Thermal anti-ice systems use electrically heated surfaces or hot air to prevent ice formation continuously, offering superior protection for larger, faster aircraft in sustained icing environments. Selecting the right system depends on aircraft size, mission profile, and typical weather conditions to ensure optimal safety and performance.

pneumatic deicing boots vs thermal anti-ice Infographic

libmatt.com

libmatt.com