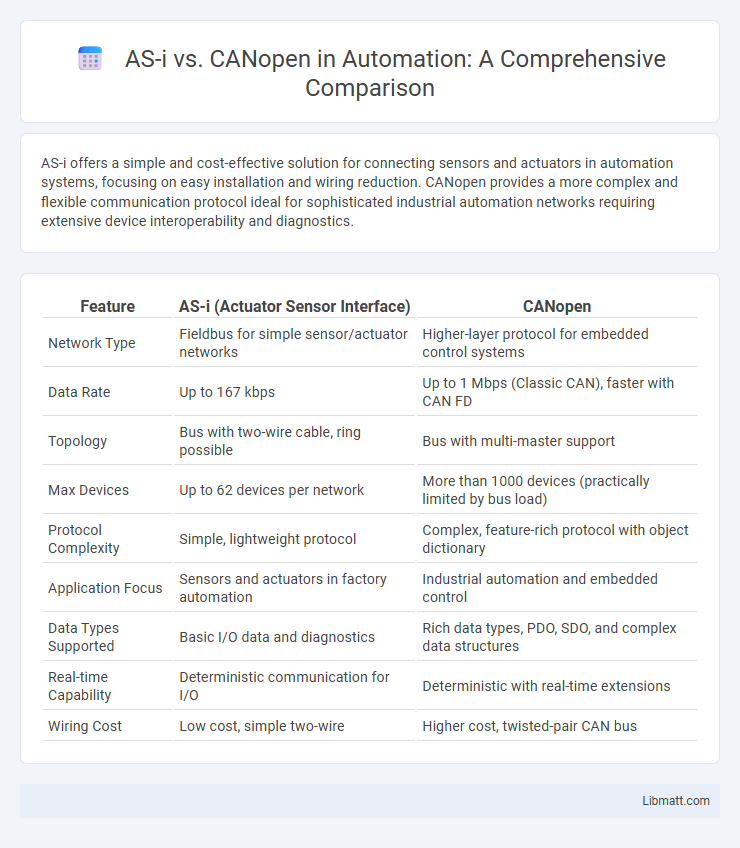

AS-i offers a simple and cost-effective solution for connecting sensors and actuators in automation systems, focusing on easy installation and wiring reduction. CANopen provides a more complex and flexible communication protocol ideal for sophisticated industrial automation networks requiring extensive device interoperability and diagnostics.

Table of Comparison

| Feature | AS-i (Actuator Sensor Interface) | CANopen |

|---|---|---|

| Network Type | Fieldbus for simple sensor/actuator networks | Higher-layer protocol for embedded control systems |

| Data Rate | Up to 167 kbps | Up to 1 Mbps (Classic CAN), faster with CAN FD |

| Topology | Bus with two-wire cable, ring possible | Bus with multi-master support |

| Max Devices | Up to 62 devices per network | More than 1000 devices (practically limited by bus load) |

| Protocol Complexity | Simple, lightweight protocol | Complex, feature-rich protocol with object dictionary |

| Application Focus | Sensors and actuators in factory automation | Industrial automation and embedded control |

| Data Types Supported | Basic I/O data and diagnostics | Rich data types, PDO, SDO, and complex data structures |

| Real-time Capability | Deterministic communication for I/O | Deterministic with real-time extensions |

| Wiring Cost | Low cost, simple two-wire | Higher cost, twisted-pair CAN bus |

Introduction to AS-i and CANopen

AS-i (Actuator Sensor Interface) is a cost-effective networking solution designed for linking simple field devices like sensors and actuators in industrial automation. CANopen, built on the CAN (Controller Area Network) protocol, supports complex device communication and real-time control in embedded systems, widely used in automotive and industrial applications. Your choice between AS-i and CANopen depends on the required network complexity, device compatibility, and application-specific performance needs.

Overview of Industrial Communication Protocols

AS-i (Actuator Sensor Interface) is a simple, cost-effective industrial communication protocol designed primarily for connecting sensors and actuators in automation networks, offering fast wiring and easy installation. CANopen, built on the robust CAN network, provides a more complex protocol suitable for real-time control and monitoring in industrial automation, with advanced features like device profiles and network management. Your choice between AS-i and CANopen depends on the required network complexity, speed, and device integration in your industrial communication system.

AS-i: Key Features and Benefits

AS-i (Actuator Sensor Interface) offers a simple, cost-effective networking solution primarily designed for connecting binary sensors and actuators in automation systems with a single two-wire cable. Its key features include easy installation, fast commissioning, and reduced wiring complexity, which significantly lowers overall system costs compared to other fieldbus technologies like CANopen. Your industrial automation applications benefit from AS-i's robust real-time communication and seamless integration with higher-level protocols, enhancing efficiency and scalability.

CANopen: Core Characteristics and Advantages

CANopen is a robust communication protocol widely used in industrial automation for its real-time data exchange and flexible device interoperability. It supports complex network topologies, facilitates easy integration of multiple devices, and offers standardized communication profiles that enhance system scalability and diagnostics. Your automation system benefits from CANopen's high reliability, efficient bandwidth usage, and extensive support for embedded control applications.

Architecture Comparison: AS-i vs CANopen

AS-i features a simple, flat bus architecture optimized for connecting binary sensors and actuators with a maximum of 31 devices per segment, prioritizing cost-effectiveness and ease of installation. CANopen is based on a layered, complex CAN network architecture supporting extensive device profiles, flexible node addressing, and advanced real-time communication for up to 127 nodes per network. The AS-i architecture excels in straightforward, low-level I/O integration, while CANopen provides scalable, high-level device interoperability and diagnostic capabilities suitable for complex industrial automation systems.

Performance and Data Transmission

AS-i (Actuator-Sensor Interface) offers a simple, cost-effective solution with data transmission speeds typically up to 167 kbps, ideal for basic sensor and actuator communication in industrial automation. CANopen, built on the robust CAN bus protocol, supports higher performance with data rates up to 1 Mbps and advanced features like real-time data exchange, error handling, and network management, making it suitable for complex machine control systems. Performance-wise, CANopen provides faster, more reliable communication and better scalability compared to AS-i, which is optimized for simpler, lower-speed networks.

Scalability and Network Size

AS-i (Actuator Sensor Interface) supports smaller network sizes typically up to 31 devices per segment, making it ideal for simple and localized automation tasks with limited scalability. CANopen, built on the Controller Area Network (CAN) protocol, accommodates larger, more complex networks with up to 127 nodes, providing greater scalability for extensive industrial applications. The inherent flexibility of CANopen supports segmented networks and advanced topologies, enabling efficient management of expansive systems compared to AS-i's simpler linear configuration.

Integration and Compatibility

AS-i offers seamless integration with sensor and actuator level devices using a simple two-wire cable system, optimizing installation costs and reducing complexity. CANopen provides broad compatibility across a wide range of industrial automation devices, supporting higher-layer protocols and standardized device profiles for flexible system configuration. Both protocols ensure interoperability, but CANopen excels in complex network topologies while AS-i is preferred for straightforward, cost-effective device-level integration.

Typical Applications and Industry Use Cases

AS-i is primarily used in simple automation tasks such as sensor and actuator networking in automotive manufacturing and packaging industries, offering cost-effective and easy integration for binary devices. CANopen excels in complex applications including mobile machinery, medical equipment, and industrial automation where real-time data exchange, scalability, and robust communication are critical. Your choice depends on the complexity of the control system and the level of network performance required for specific industry use cases.

Choosing Between AS-i and CANopen

Choosing between AS-i and CANopen depends on the specific industrial automation needs and network complexity. AS-i offers a cost-effective and simple solution for connecting sensors and actuators with a focus on low data rates and easy installation. CANopen supports higher data throughput, advanced device profiles, and flexible topology, making it suitable for complex, safety-critical, or multi-vendor environments.

AS-i vs CANopen Infographic

libmatt.com

libmatt.com